Method for enhancing oil recovery of low permeability sandstone reservoir

A sandstone reservoir, low-permeability technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of low average permeability of the formation, loss of oil displacement, and reduced viscosity, and achieve improved crude oil recovery. Yield, good water dispersibility, good elasticity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The method for improving the oil recovery rate in the late stage of fracturing water injection in ultra-low permeability sandstone reservoirs, the steps are as follows:

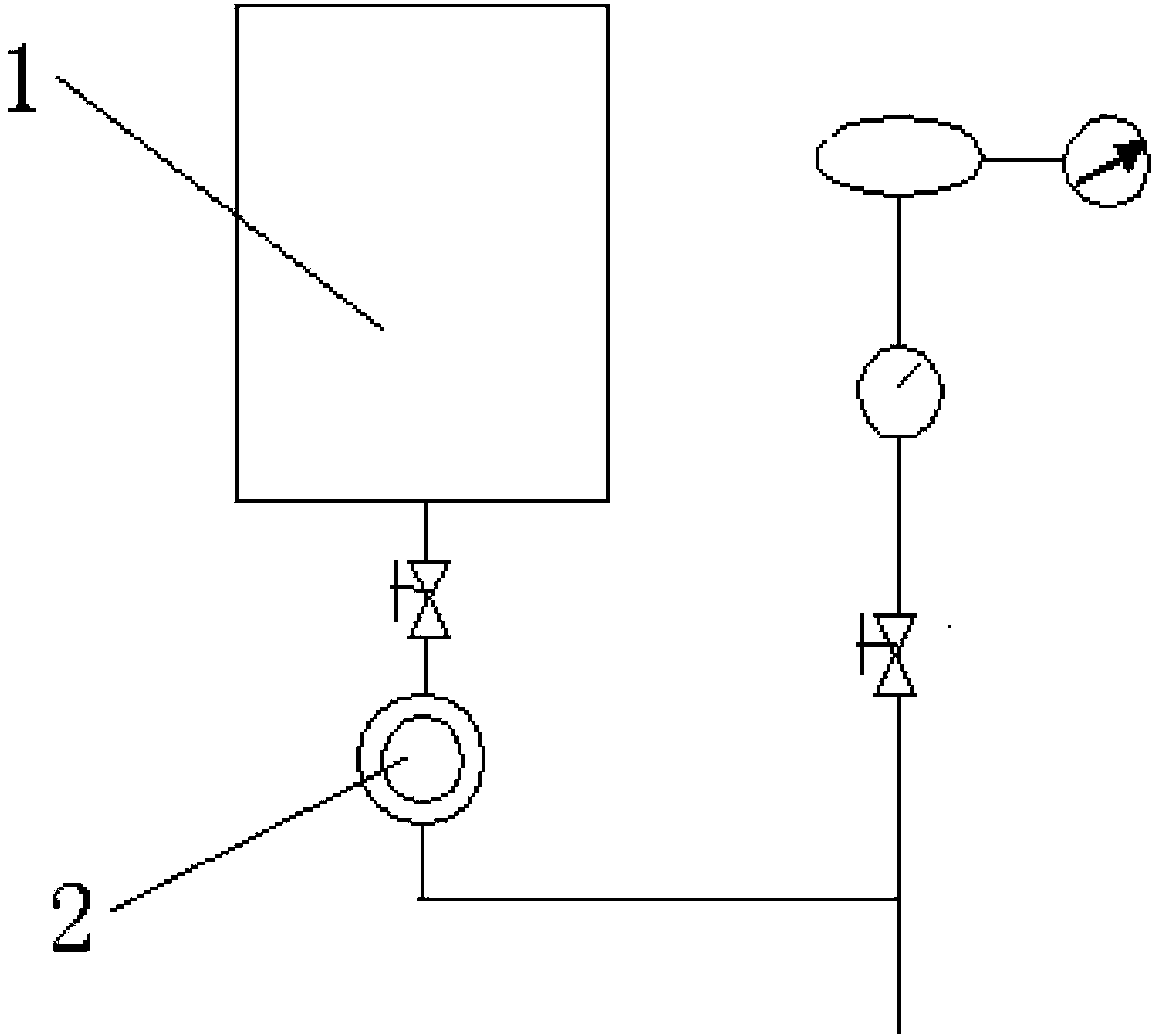

[0019] The average permeability of the ultra-low permeability sandstone reservoir formation is 0.6 mD, the daily water injection volume of the water injection well is 30 tons, and the soft microgel deep control and displacement agent is selected. The initial average particle size is 106nm. The equipment is connected as attached figure 1 As shown, the flexible microgel deep water control agent is placed in the storage tank 1, and the pump speed of the metering pump 2 is controlled to make the injected water control agent concentration 1000ppm. After continuous injection for 12 months, stop, and then continue to inject water separately , corresponding to 8% cumulative increase in oil wells, and a duration of 2.5 years for stable and increased production.

Embodiment 2

[0021] The method for improving the oil recovery rate in the late stage of fracturing water injection in ultra-low permeability sandstone reservoirs, the steps are as follows:

[0022] The average permeability of the ultra-low permeability sandstone reservoir formation is 0.9 mD, and the daily water injection volume of the water injection well is 40 tons. The soft microgel deep control and displacement agent is selected, and the initial average particle size is 200nm. The equipment is connected as attached figure 1 As shown, the flexible microgel deep water-regulating agent is placed in the storage tank 1, and the pumping speed of the metering pump 2 is controlled so that the concentration of the injected water-controlling agent is 5000ppm. After continuous injection for 6 months, stop, and then continue to inject water separately , corresponding to a 5% cumulative increase in oil wells, and a duration of 1.5 years for stable and increased production.

Embodiment 3

[0024] The method for improving the oil recovery rate in the late stage of fracturing water injection in ultra-low permeability sandstone reservoirs, the steps are as follows:

[0025] The average permeability of the ultra-low permeability sandstone reservoir formation is 0.2 mD, the daily water injection volume of the water injection well is 20 tons, and the soft microgel deep control and displacement agent is selected, the initial average particle size is 20nm, and the equipment is connected as attached figure 1 As shown, the flexible microgel deep water-regulating agent is placed in the storage tank 1, and the pumping speed of the metering pump 2 is controlled so that the concentration of the injected water-controlling agent is 100ppm. After continuous injection for 36 months, stop, and then continue to inject water separately , corresponding to a cumulative oil increase of 10% for oil wells, and a period of 5 years for stable and increased production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com