Absorption structure of compressor

A technology for compressors and suction parts, which is applied to mechanical equipment, machines/engines, liquid displacement machinery, etc., and can solve problems such as poor startup, slow startup of the prime mover 150, and stagnation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

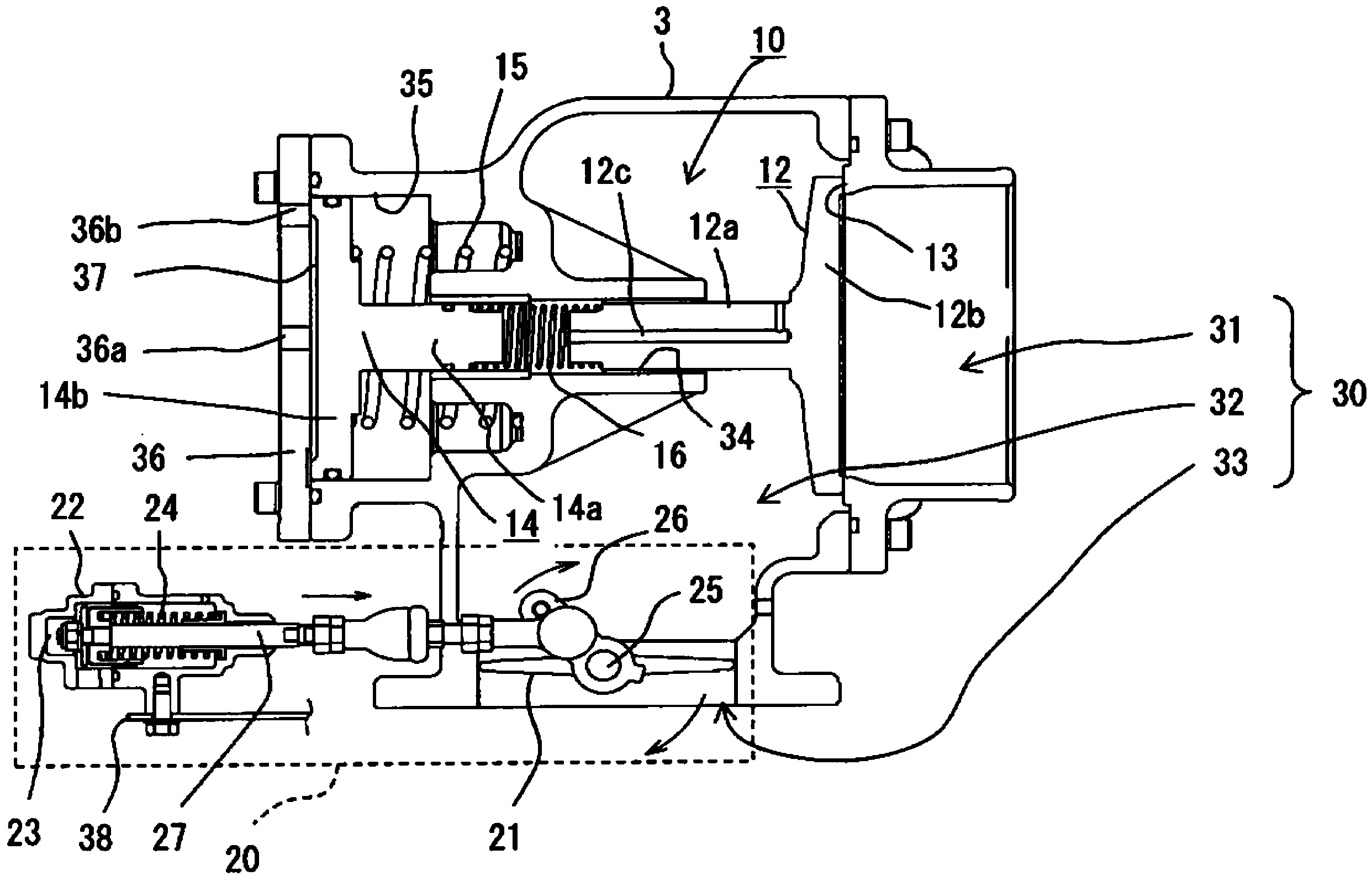

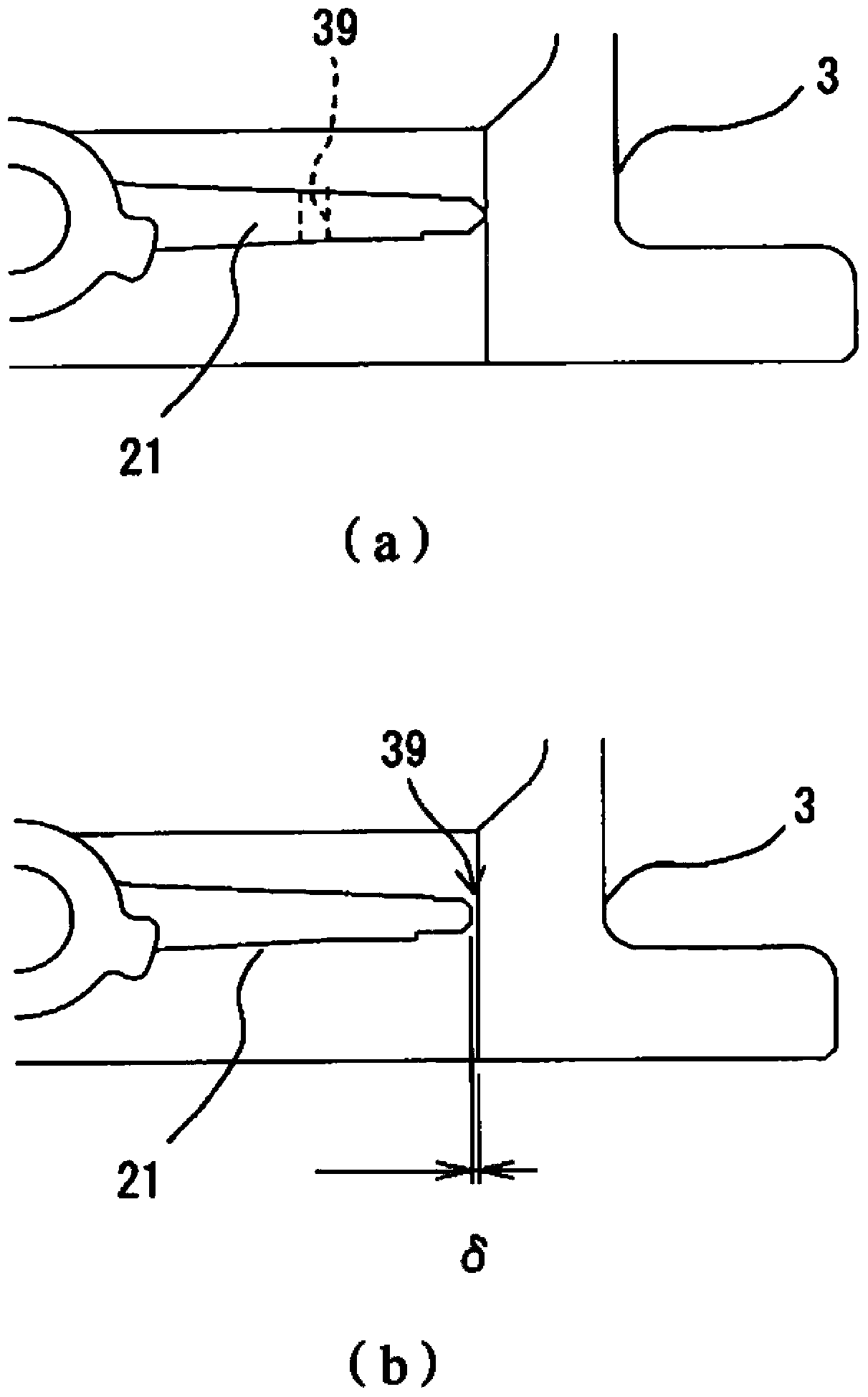

[0133] Hereinafter, the compressor of the present invention will be described with reference to the drawings.

[0134] 〔Structure of the compressor〕

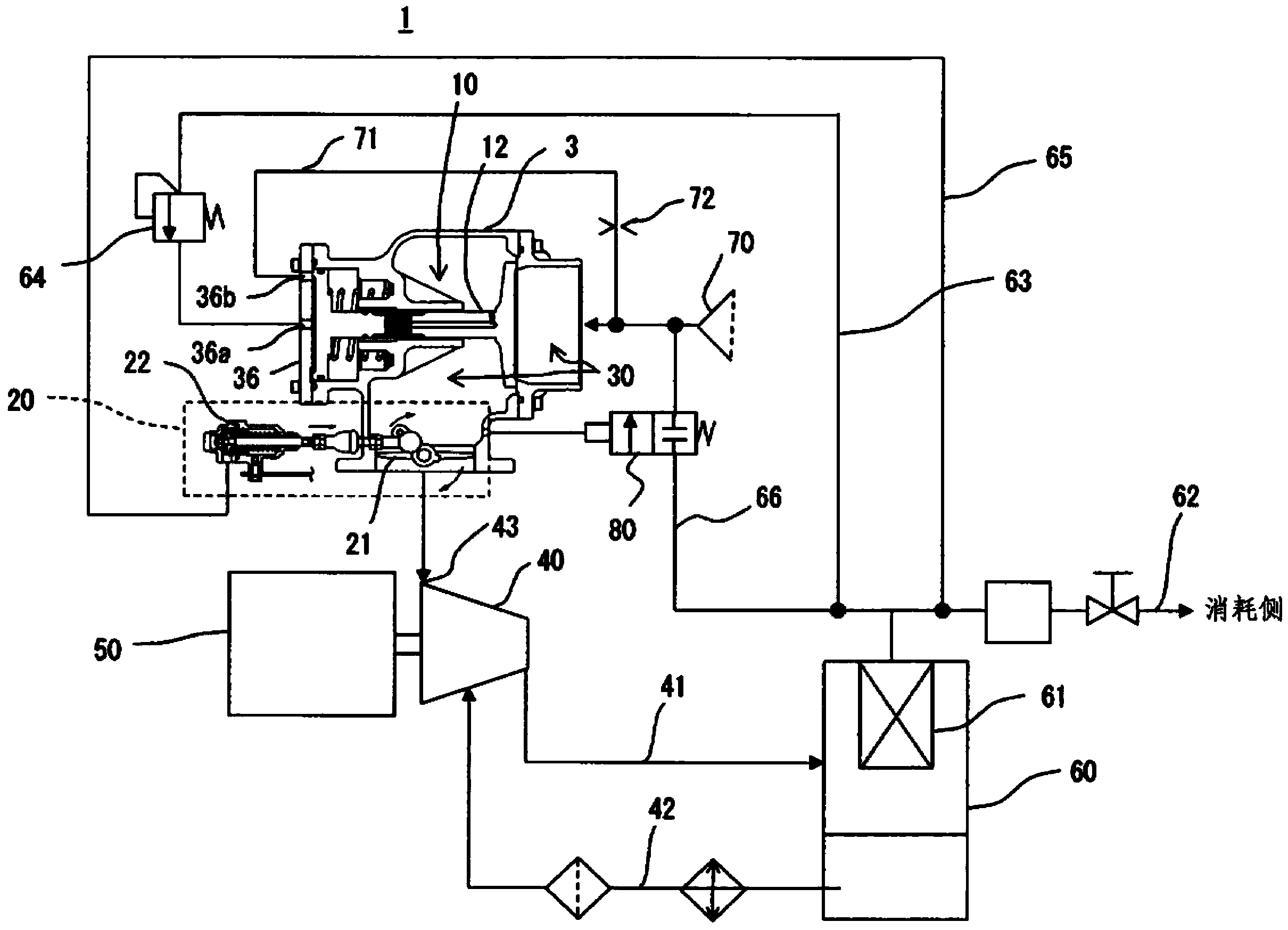

[0135] figure 1 The reference numeral 1 in is the compressor of the present invention, and the compressor 1 includes a compressor main body 40, a prime mover 50 such as an engine or an electric motor that drives the compressor main body 40, and storage from the compressor main body 40 The storage tank 60 for the ejected compressed gas. The compressed gas discharged from the compressor main body 40 is stored in the accumulator 60 , and can be supplied to the consumption side connected with an unshown air working machine or the like through a supply circuit 62 communicating with the accumulator 60 .

[0136] In this embodiment, the above-mentioned compressor body 40 uses an oil-cooled screw compressor, and a separator 61 is provided in the storage tank 60, which is used to dissipate the gas from the gas-liquid mixed fluid with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com