A kind of ice nano-indentation sample platform and related experimental method

A nano-indentation and nano-indentation instrument technology, which is applied in the direction of testing material hardness, measuring devices, instruments, etc., can solve the problems of large surface roughness, contamination of the sample surface, temperature rise, etc., and achieve simple material preparation and optimized experiments Process, the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

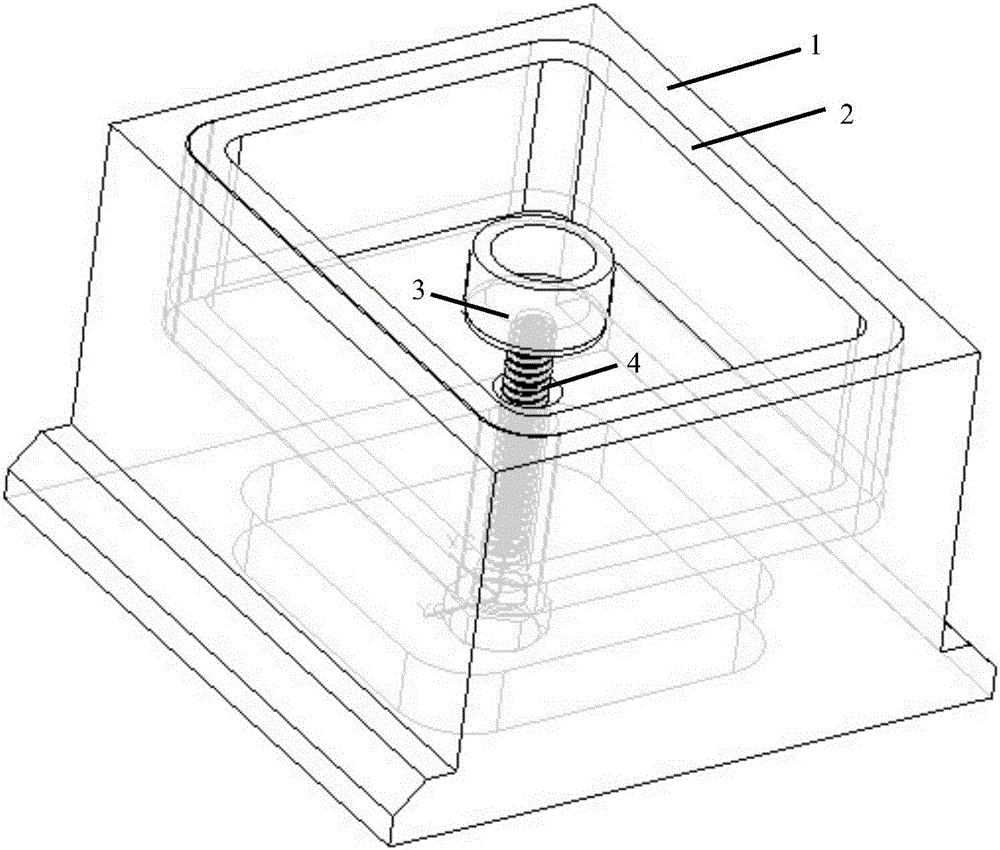

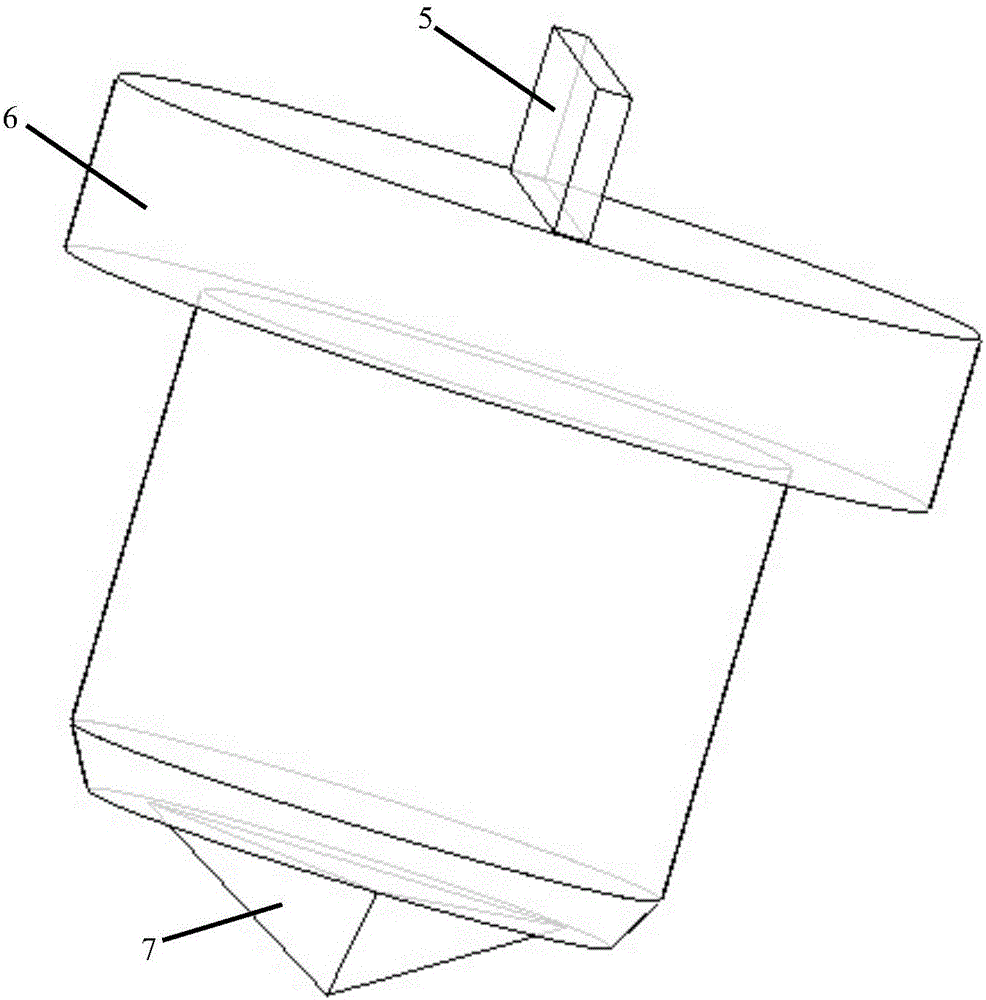

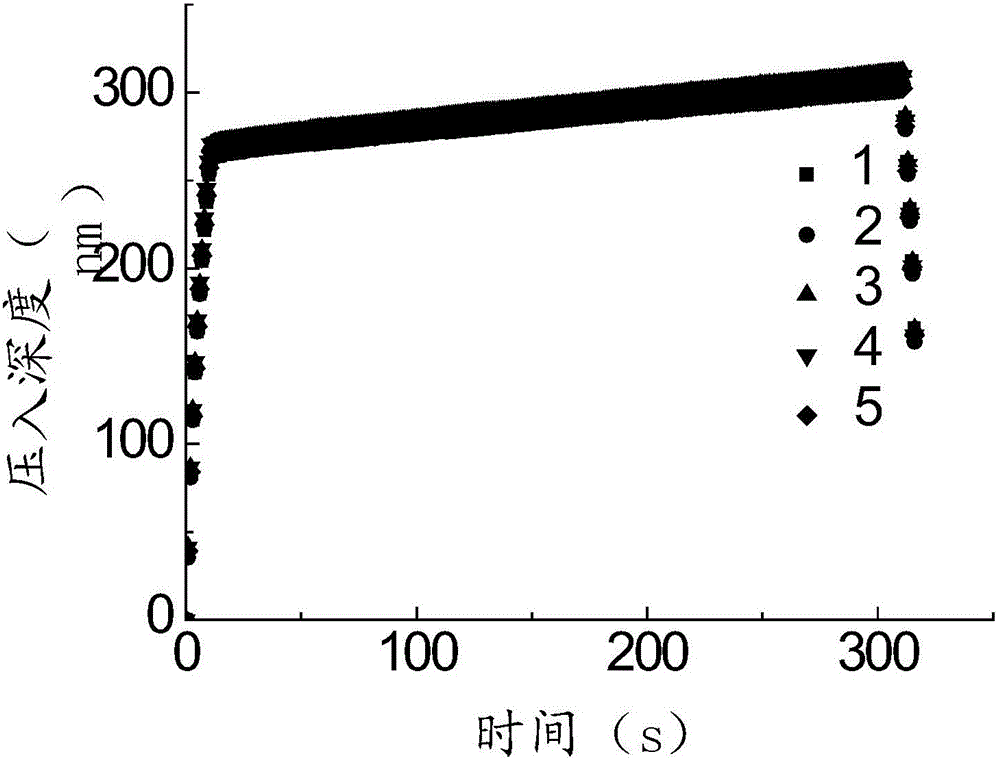

[0022] When using the ice nano-indentation sample stage to test the mechanical properties of the resin film in a low temperature environment, first put the glass block as the base material into the holding tank II3, and the height of the glass block is 200 microns lower than the edge height of the holding tank II3. Pour the well-stirred resin on the surface of the glass block, the height of the resin is about 1 mm higher than the container II3, pour the cooling material dry ice into the container I1, and grind the surface with 3000-grit sandpaper for 1 minute after 15 minutes to make the resin The height is the same as the height of the edge of the receiving groove II3, and continue to polish for 1 minute through the tweed. Install the indenter into the indenter fixture of the nanoindenter, and the sample stage into the sample fixture of the nanoindenter. Adjust the height of the lifting device to ensure that the height of the ice body meets the test height of the nano-indente...

example 2

[0024] When using the ice nanoindentation sample stage to test the mechanical properties of the shape memory polymer film in a low temperature environment, the glass block as the base material is first loaded into the holding tank II3, and the height of the glass block is lower than the edge height of the holding tank II3 200 microns, pour the evenly stirred shape memory polymer on the surface of the glass block, the height of the shape memory polymer is about 31 mm higher than the container II, pour the cooling material dry ice into the container I1, and pass 1500 grit sandpaper after half an hour Grind the surface for 1 minute, and grind the surface with 2000-grit sandpaper for 1 minute, so that the height of the shape memory polymer film is the same as the height of the edge of the receiving groove II3. Install the indenter into the indenter fixture of the nanoindenter, and the sample stage into the sample fixture of the nanoindenter. Adjust the height of the lifting platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com