Method and system for image analysis of gear collision/damage deformation process

An image analysis and gear technology, which is applied in image communication, closed-circuit television system, TV system components, etc., can solve the problems of low detection accuracy and unintuitive results, achieve high signal reliability, improve credibility and reliability, The effect of high-precision real-time tracking detection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] A method for image analysis of gear collision / damage deformation process, comprising the following steps:

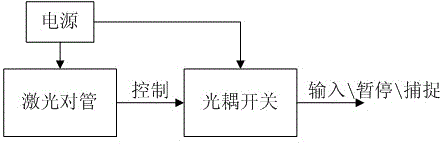

[0028] 1) There is a strain gauge at the tooth root of the tested mechanical gear; there is a shooting hole on the tooth of the gear, and a laser shooting tube is provided at the position where the signal can be received directly in front of and directly behind the shooting hole;

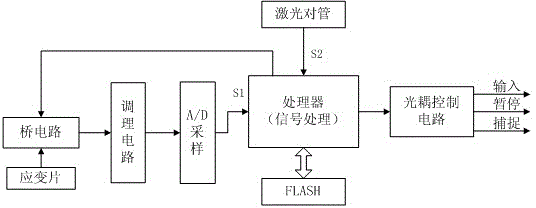

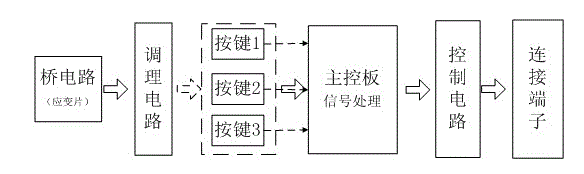

[0029] 2) Under the working condition of the mechanical gear under test, the deformation signal of the strain gauge after the collision and the laser signal of the laser tube are collected synchronously, and the processor monitors and synchronously triggers the deformation signal and the laser signal in real time Control, control the high-speed camera for real-time video recording;

[0030] 3) Based on the images captured by the high-speed cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com