Refrigerator

A technology for refrigerators and cold rooms, applied in the field of refrigerators, which can solve the problems of reducing the amount of frost in coolers 105, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

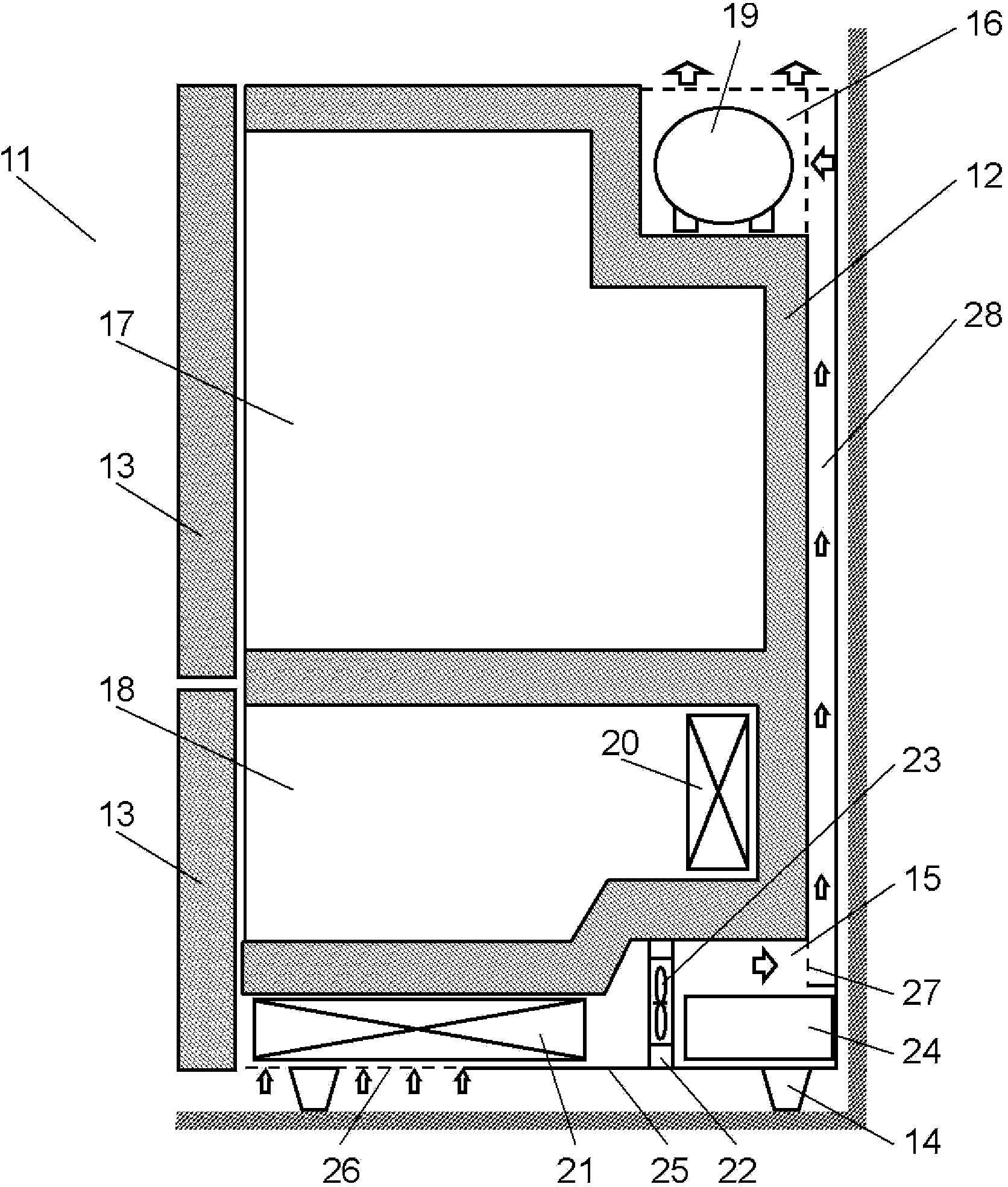

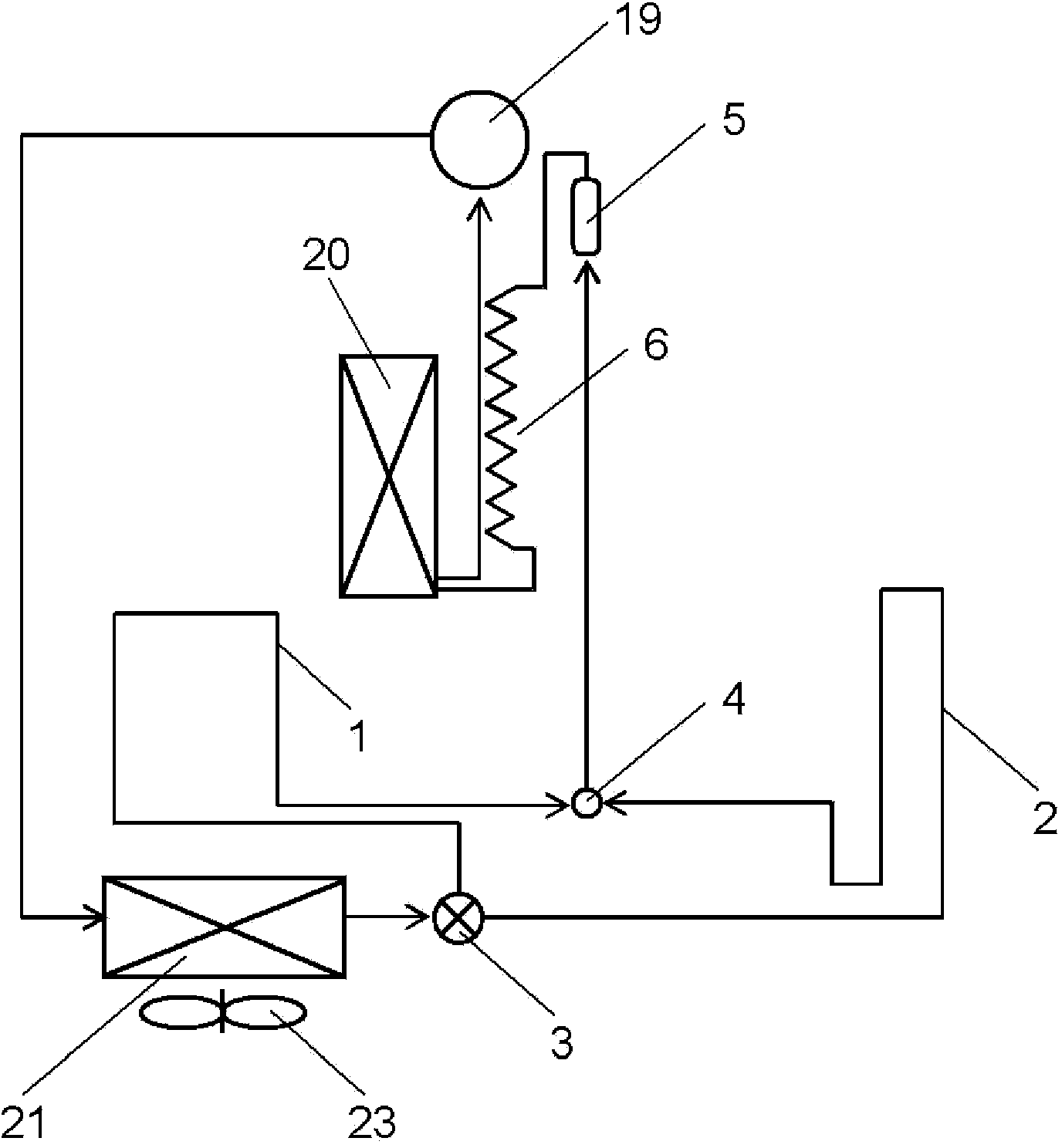

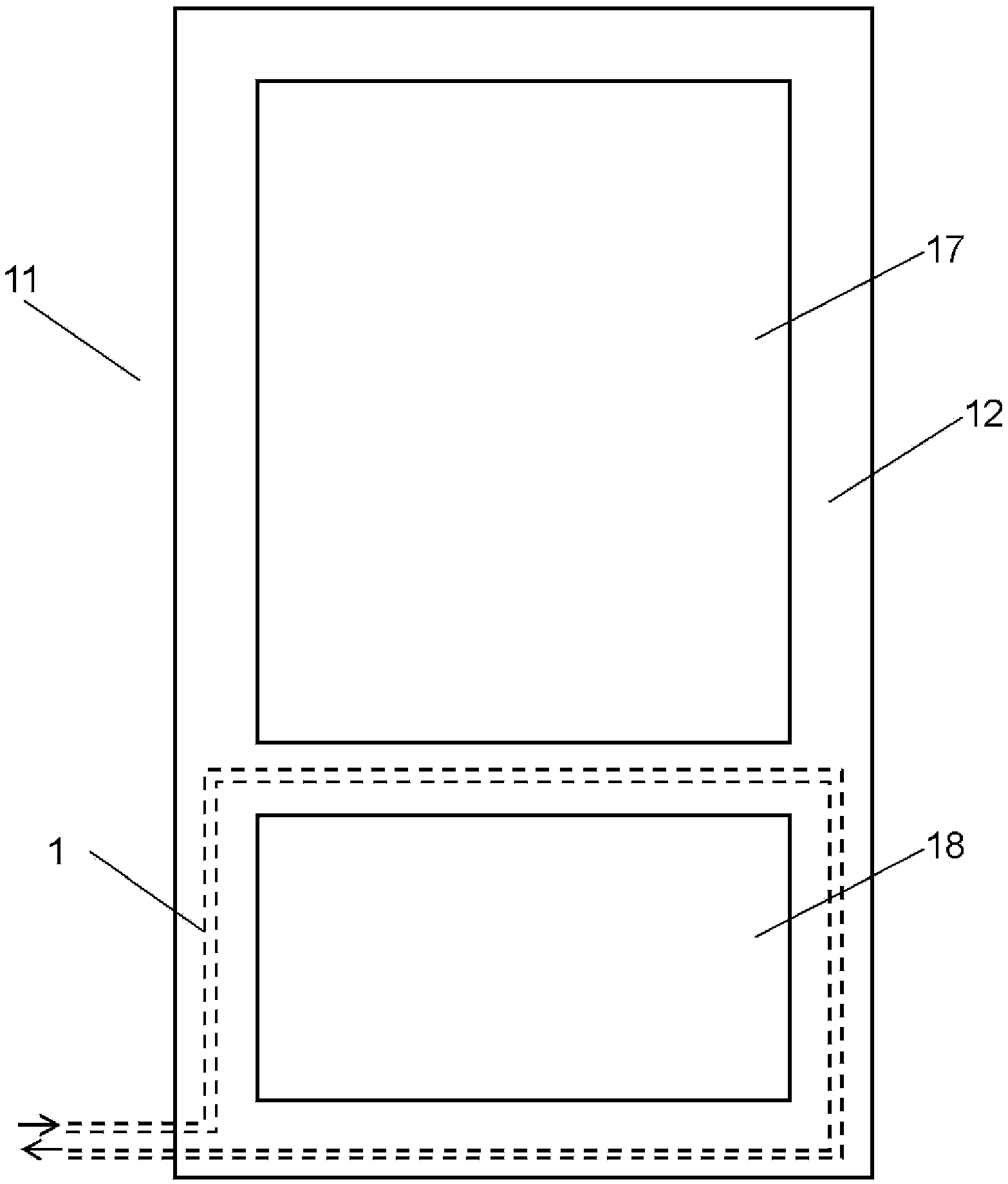

[0125] figure 1 It is a longitudinal sectional view of the refrigerator in the first embodiment of the present invention, figure 2 is a cycle configuration diagram of the refrigerator in the first embodiment of the present invention, image 3 is a schematic diagram of the front of the refrigerator in the first embodiment of the present invention, Figure 4 is a schematic diagram of the back of the refrigerator in the first embodiment of the present invention, Figure 5 It is a schematic diagram of the control pattern of the refrigerator in 1st Embodiment of this invention.

[0126] exist figure 1 Among them, the refrigerator 11 includes: a box body 12, a door 13, a foot 14 supporting the box body 12, and is formed with a lower machine room 15 arranged at the bottom of the box body 12, an upper machine room 16 arranged at the upper part of the back side of the box body 12, Refrigerating room 17 as a store room arranged at the upper part of box body 12 and freezer room 18...

no. 2 approach )

[0156] Image 6 It is a longitudinal sectional view of the refrigerator in 2nd Embodiment of this invention, Figure 7 is a cycle configuration diagram of the refrigerator in the second embodiment of the present invention, Figure 8 is a dynamic waveform diagram of the temperature sensor of the refrigerator in the second embodiment of the present invention, Figure 9 It is a flowchart which shows the control at the time of defrosting of the refrigerator in 2nd Embodiment of this invention.

[0157] exist Image 6 and Figure 7 Among them, the refrigerator 11 has: a box body 12, a door 13, a foot 14 supporting the box body 12, a lower machine room 15 arranged at the bottom of the box body 12, an upper machine room 16 arranged at the top of the box body 12, and a The refrigerating chamber 17 on the upper part of the housing 12 and the freezing chamber 18 on the lower part of the casing 12 are arranged. Also, components constituting the refrigeration cycle include a compress...

no. 3 approach )

[0193] Figure 10 It is a longitudinal sectional view of the refrigerator in the 3rd Embodiment of this invention, Figure 11 is a cycle configuration diagram of the refrigerator in the third embodiment of the present invention, Figure 12 It is a waveform diagram of the dynamics of the temperature sensor of the refrigerator in the third embodiment of the present invention.

[0194] exist Figure 10 and Figure 11 Among them, the refrigerator 11 has: a box body 12, a door 13, a leg 14 supporting the box body 12, a lower machine room 15 arranged at the lower part of the box body 12, an upper machine room 16 arranged at the upper part of the box body 12, and an upper machine room 16 arranged at the box body 12. The refrigerating chamber 17 on the upper part of the housing 12 and the freezing chamber 18 on the lower part of the casing 12 are arranged. Also, components constituting the refrigeration cycle include a compressor 19 housed in the upper machine compartment 16 , an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com