Method for spraying silicone rubber paint layer on engine shell

A technology for engine casings and silicone rubber, which is applied to coatings, devices for coating liquid on the surface, spraying devices, etc., and can solve problems such as low coating efficiency and poor coating quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

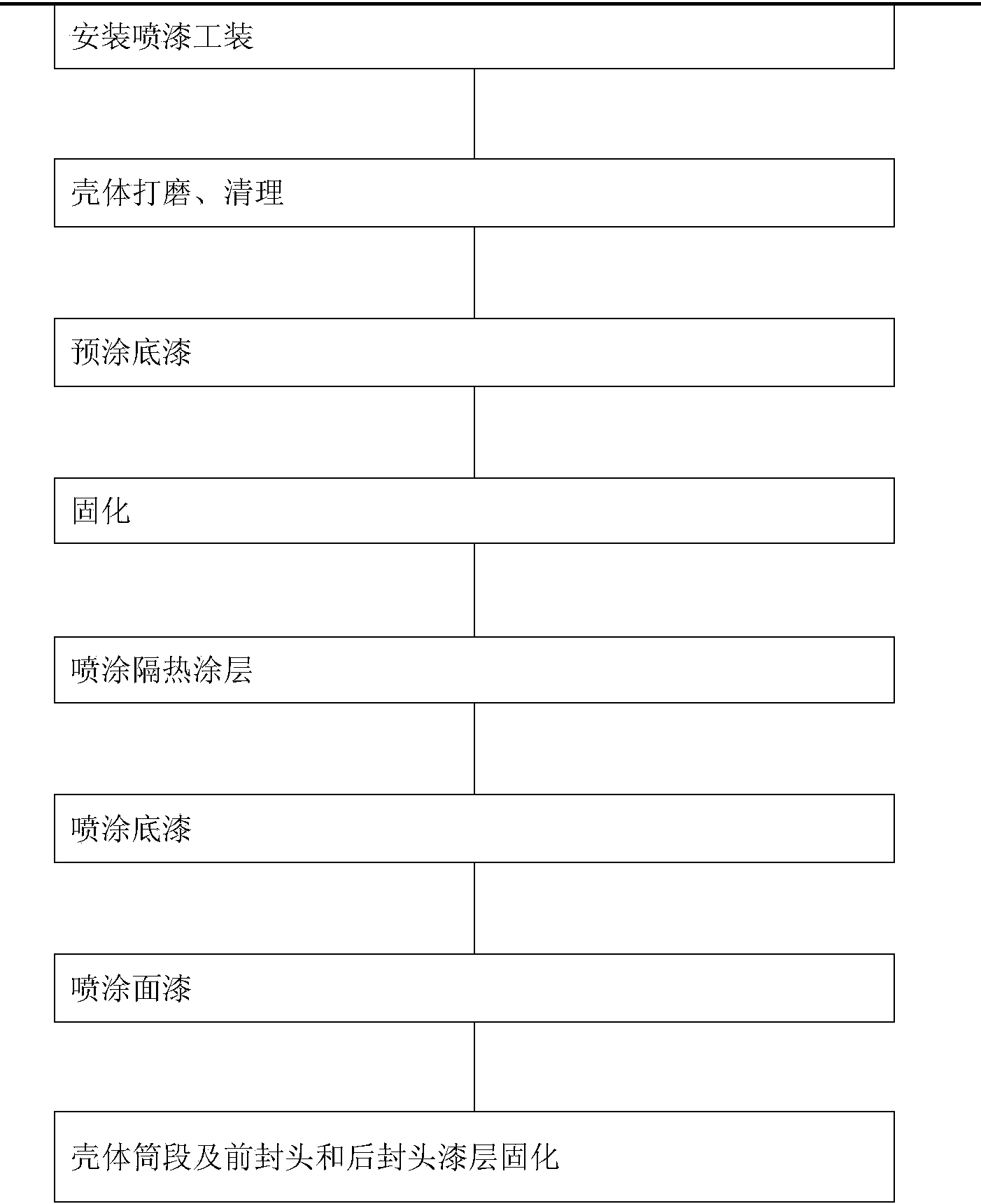

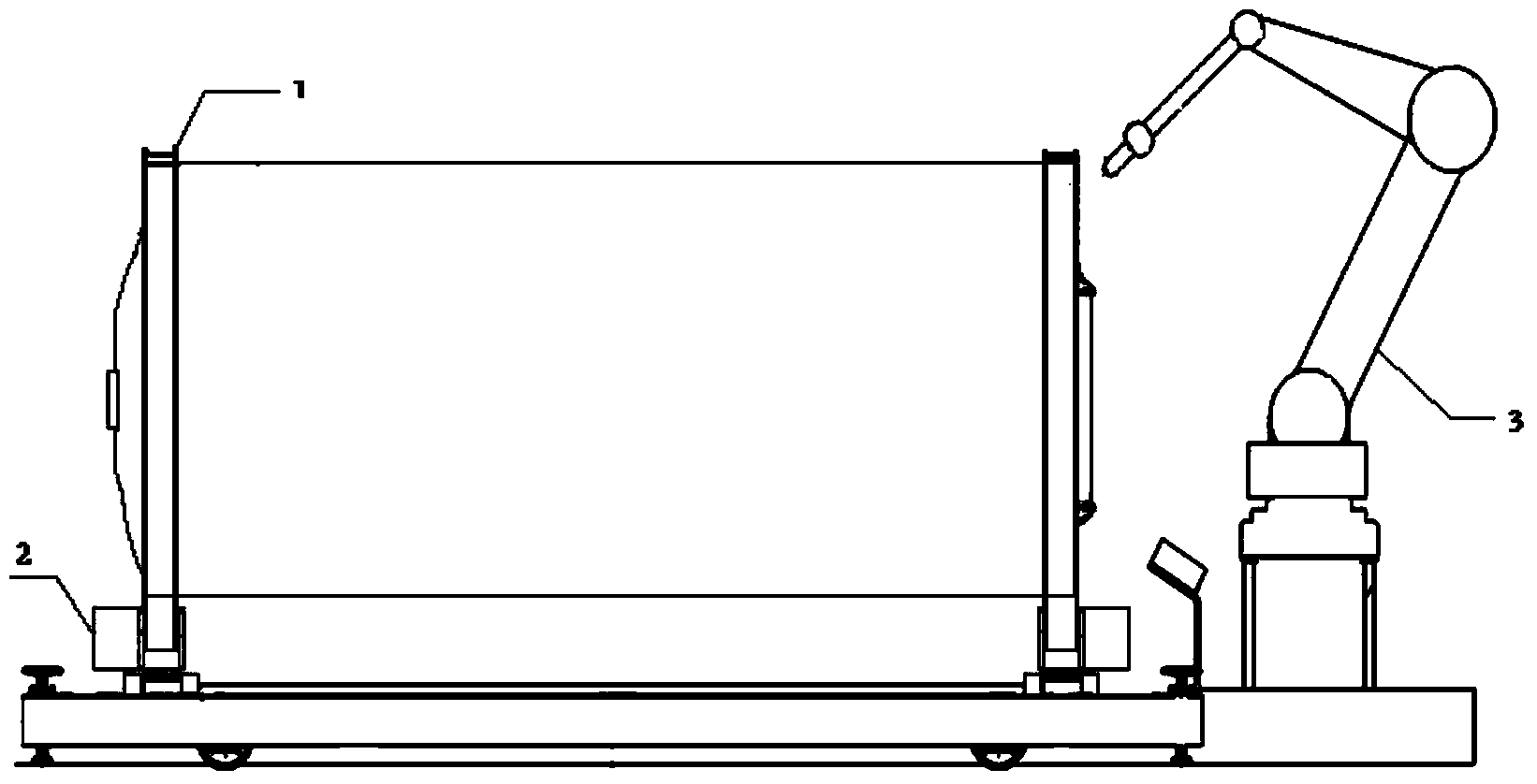

[0082] This embodiment is a method for spraying an engine casing with a diameter of 2000 mm. The geometric structure of the outer surface of the casing is mainly composed of a cylindrical straight cylinder surface and an ellipsoidal head with two central openings. The specific process is:

[0083] Step 1: Install the painting tooling. During installation, the engine casing is hoisted on the paint-spraying turning car 2, and the painting tooling 1 is installed on the skirt end faces of the two ends of the engine casing, and the described painting tooling is positioned in the roller groove of the turning car; the painting tooling and the roller groove There is no interference between the groove walls. The painting tooling and turning car are the same as the tooling and turning car used when spraying the engine casing in the prior art.

[0084] Step 2: Shell grinding and cleaning. Use 120-grit sandpaper to polish the front and rear heads along the fiber direction; use 80-grit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com