The cold forging production process of the pressure box gland of the tiller

A production process and micro-tiller technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of high production cost, billet fracture, large forging, etc., achieve good surface quality and save production The effect of high cost and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0061] The cold forging production process of the tiller pressure box gland of the present embodiment comprises the following steps:

[0062] 1) Blanking, punching the blank into a disc-shaped blank;

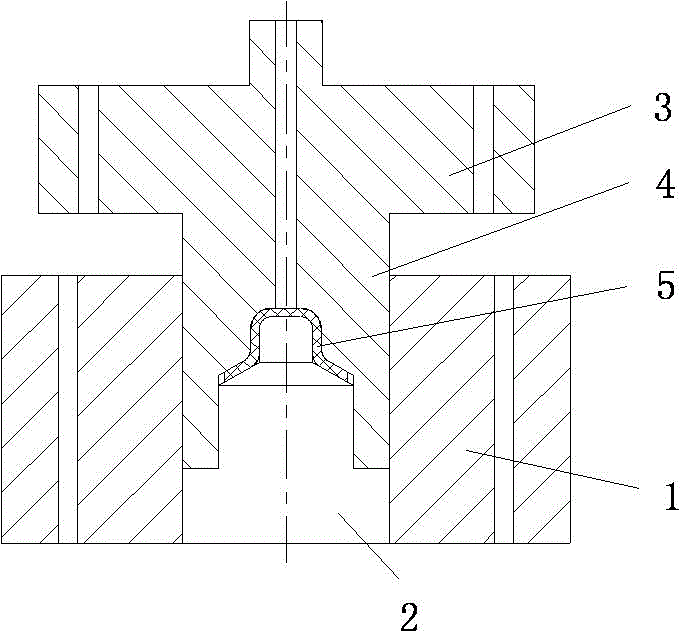

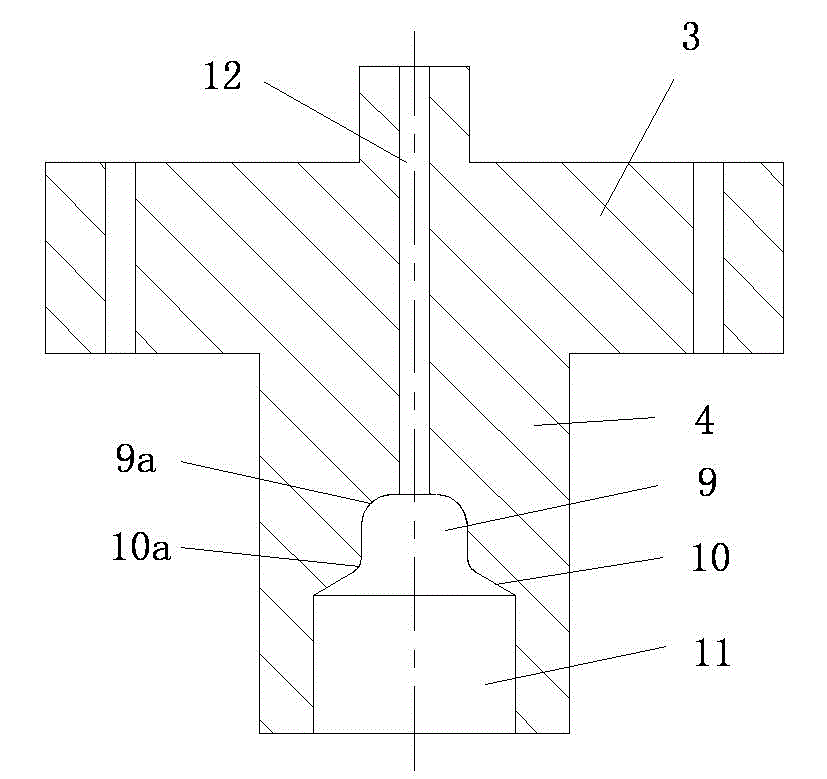

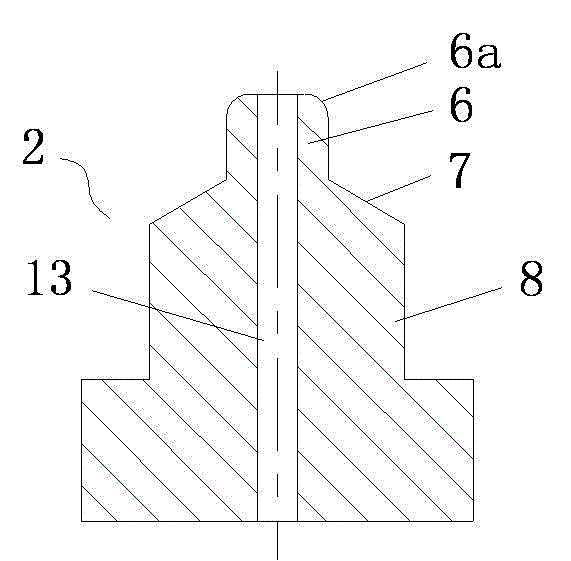

[0063] 2) One-ring cold forging: use the above-mentioned one-ring cold forging die to cold-forge the billet into a transition gland 5, and the arc transition between the top surface of the transition gland 5 and the top side wall of the transition gland 5, the radius of the arc It is equal to 1 / 4 of the diameter of the transition gland cover top 5a, and the cover edge 5b of the transition gland is tapered, and its taper is 115°, that is, the taper of the lower tapered surface 7 and the upper tapered surface 10 is taken as 115°, The radius of the transition arc I 6a is equal to 1 / 4 of the diameter of the top of the transition gland;

[0064] 3) Two-ring cold forging: using the above-mentioned two-ring cold forging die to cold forge the transition gland 5 into a gland forging 14;...

no. 2 example

[0068] The cold forging production process of the tiller pressure box gland of the present embodiment comprises the following steps:

[0069] 1) Blanking, punching the blank into a disc-shaped blank;

[0070] 2) One-ring cold forging: use the above-mentioned one-ring cold forging die to cold-forge the billet into a transition gland 5, and the arc transition between the top surface of the transition gland 5 and the top side wall of the transition gland 5, the radius of the arc It is equal to 1 / 3 of the diameter of the transition gland cover top 5a, and the cover edge 5b of the transition gland is tapered, and its taper is 120°, that is, the taper of the lower tapered surface 7 and the upper tapered surface 10 is taken as 120°, The radius of the transition arc I 6a is equal to 1 / 3 of the diameter of the top of the transition gland;

[0071] 3) Two-ring cold forging: using the above-mentioned two-ring cold forging die to cold forge the transition gland 5 into a gland forging 14;...

no. 3 example

[0075] The cold forging production process of the tiller pressure box gland of the present embodiment comprises the following steps:

[0076] 1) Blanking, punching the blank into a disc-shaped blank;

[0077] 2) One-ring cold forging: use the above-mentioned one-ring cold forging die to cold-forge the billet into a transition gland 5, and the arc transition between the top surface of the transition gland 5 and the top side wall of the transition gland 5, the radius of the arc It is equal to 2 / 7 of the diameter of the transition gland cover top 5a, and the cover edge 5b of the transition gland is tapered, and its taper is 125°, that is, the taper of the lower tapered surface 7 and the upper tapered surface 10 is taken as 125°, The radius of the transition arc I 6a is equal to 2 / 7 of the top diameter of the transition gland;

[0078] 3) Two-ring cold forging: using the above-mentioned two-ring cold forging die to cold forge the transition gland 5 into a gland forging 14;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com