Profile cutting machine

A cutting machine and profile technology, applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as hidden safety hazards and low cutting efficiency of large profiles, so as to improve work efficiency, eliminate unsafe factors, and ensure health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

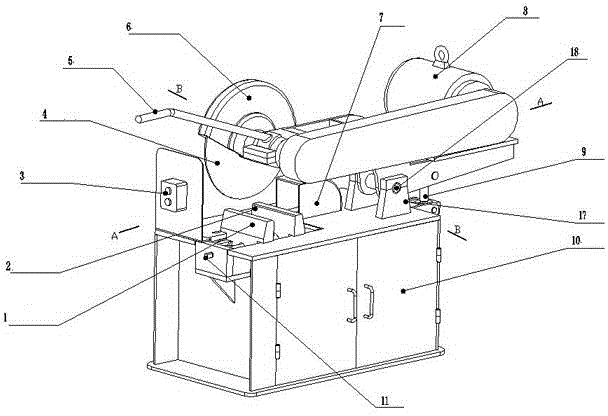

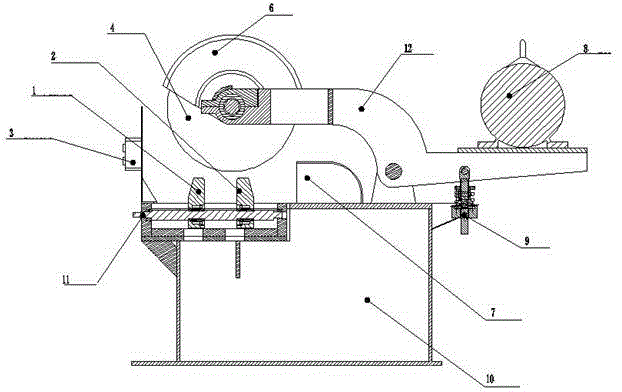

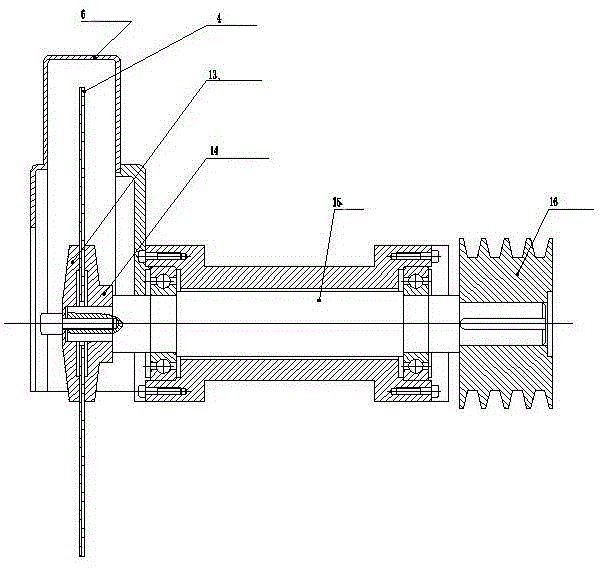

[0012] For better understanding and implementation, the profile cutting machine of the present invention will be described in detail below in conjunction with the accompanying drawings, including a box platform 10, a bracket 17 and a power switch 3 are provided on the box platform 10, and a hinge shaft 18 is provided on the bracket 17 Frame 12, frame 12 rear end is provided with motor 8, and front end is provided with axle 15, and axle 15 one end is provided with belt pulley 16, and the other end is provided with emery wheel seat plate 14, emery wheel pressing plate 13, between emery wheel seat plate 14, emery wheel pressing plate 13 There is a grinding wheel piece 4 between them, the pulley 16 is connected with the motor 8 by a belt, and the box platform 10 is provided with a clamping clamp I1 and a clamping clamp II2, and the clamping clamp I1 and clamping clamp II2 are connected with the left-handed screw on the lead screw 11 respectively. The thread and the right-handed thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com