Automatic sandblast derusting equipment for artillery shells

A sandblasting and rust removal, automatic technology, used in metal processing equipment, spray guns, abrasive jet machine tools, etc., can solve problems such as low processing efficiency, complex machine adjustment, unreasonable structure, etc. Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

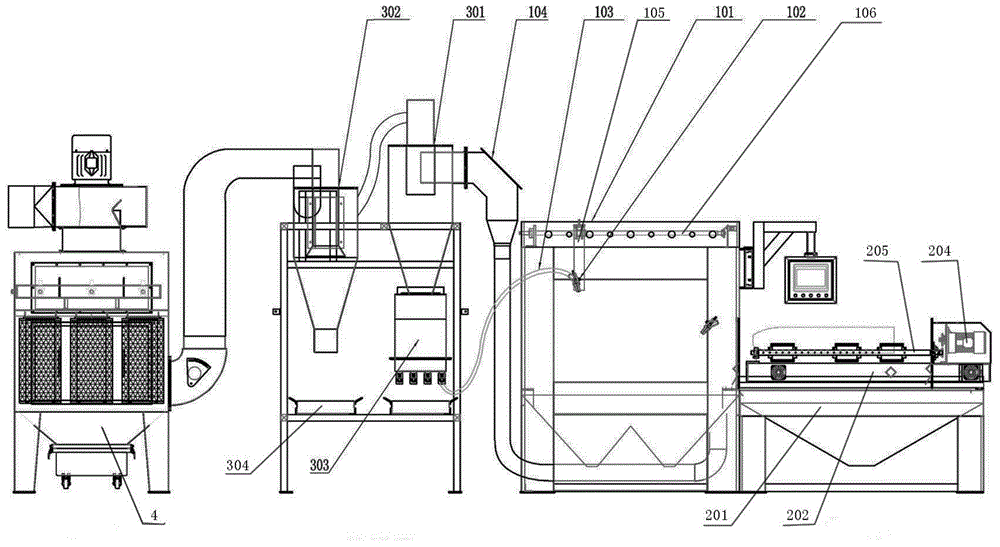

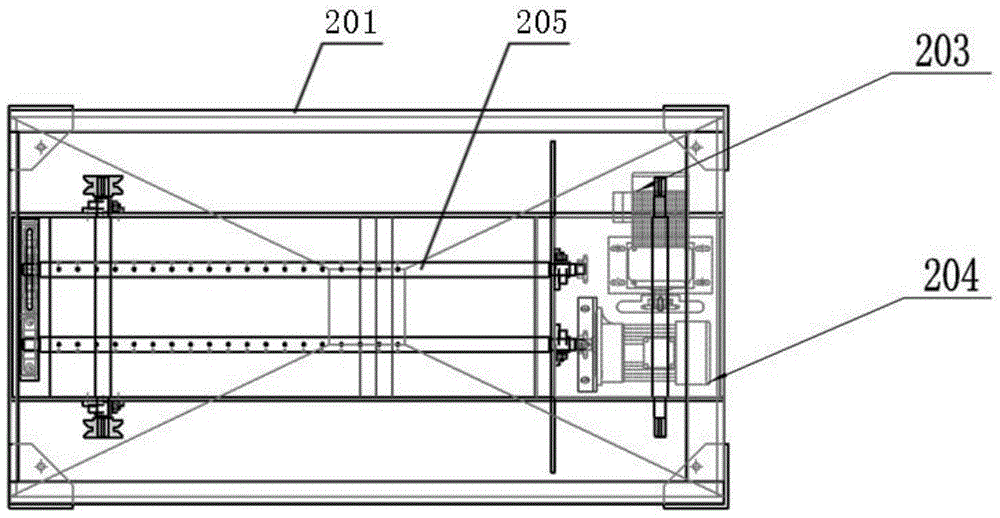

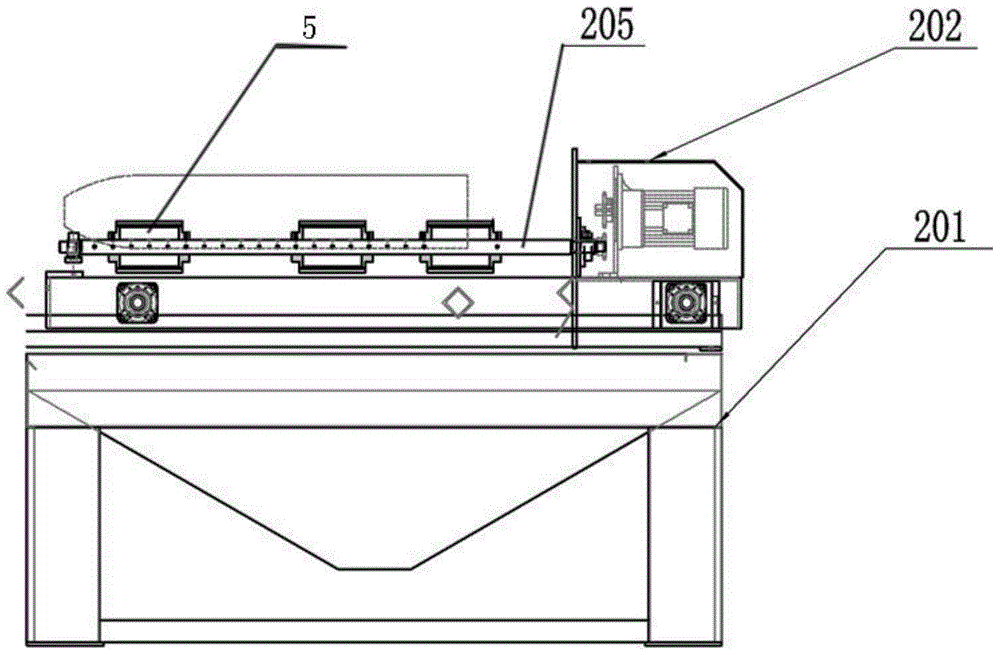

[0023] An automatic sandblasting and derusting equipment for shells, including a main machine, a trolley mechanism, a cyclone separator and a dust collector;

[0024] Such as figure 1 As shown, the main engine includes a machine body 101, a spray gun mechanism, a sand supply pipeline 103 and a dust extraction pipeline 104. The cyclone separator is connected, and the other end is connected with the spray gun mechanism; the cyclone separator is connected with the dust collector 4 .

[0025] The cyclone separator includes a primary cyclone separator 301, a secondary cyclone separator 302 and a sand storage device 303, the dust extraction pipeline 104 is connected to the primary cyclone separator 301, and the primary c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com