A dismantling device and dismantling method for a touch screen and a liquid crystal display

A liquid crystal display, touch screen technology, applied in metal processing and other directions, can solve the problems of low yield and material waste of touch screen and display screen, and achieve the effect of alleviating low stability, avoiding damage, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

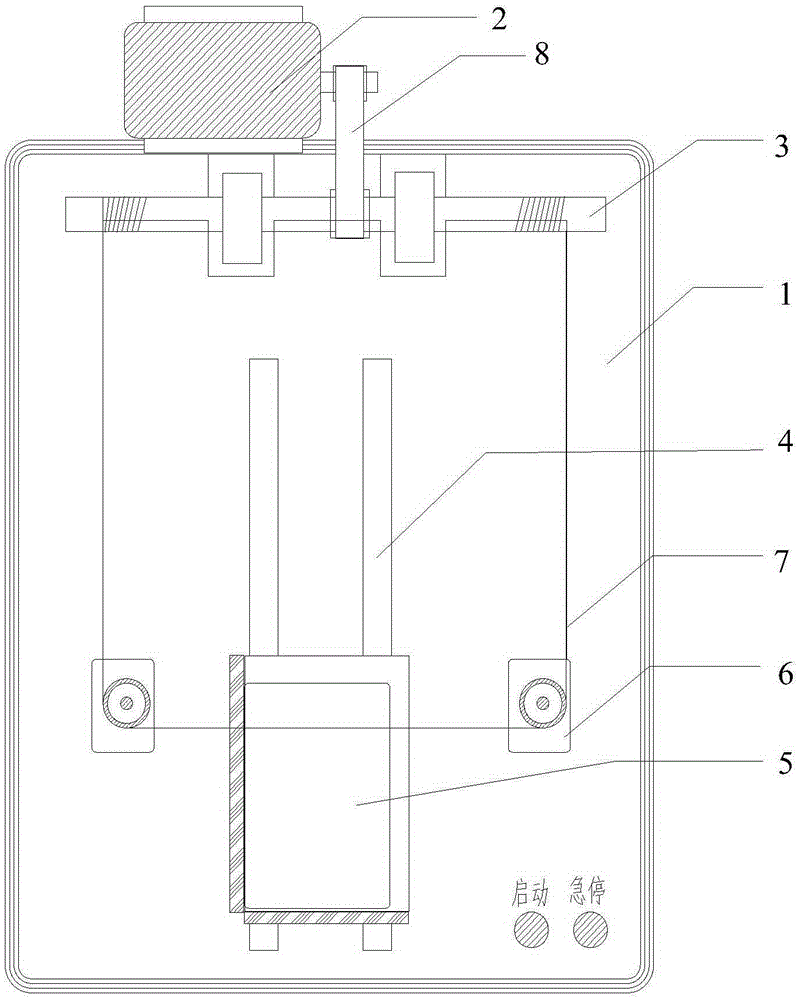

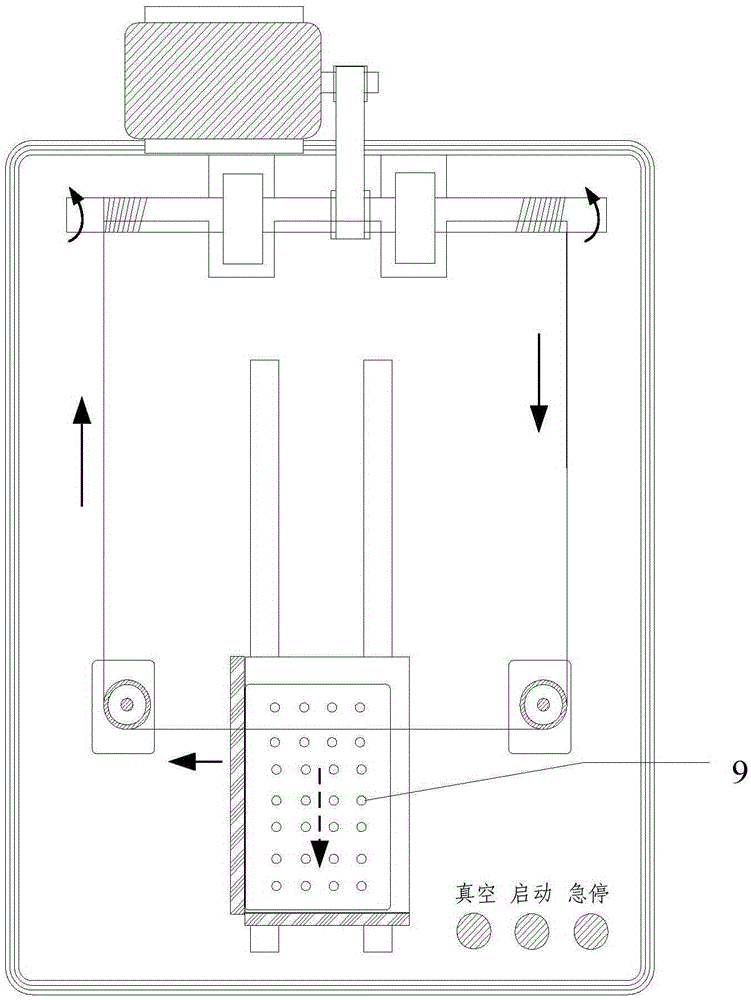

[0056] A dismantling device for a touch screen and a liquid crystal display disclosed in an embodiment of the present invention, such as figure 1 As shown, it includes a working platform 1, a motor 2, a winding shaft 3, a guide rail 4, a jig 5, a rotor 6 and a steel wire 7.

[0057] Wherein, the working platform 1 is a supporting mechanism of the dismantling device, and the working platform 1 may be a rectangular box or a solid workbench, which is not limited in this embodiment. It should be noted that, in this embodiment, the working platform 1 is preferably a box structure, and items can be placed inside it, such as a governor connected to the motor for adjusting the speed of the motor, a power supply for providing electric energy to the motor, and The control circuit and the like of the entire dismantling device (not shown in the figure), the corresponding working platform may also include buttons corresponding to the controller, so as to facilitate the operator to control ...

Embodiment 2

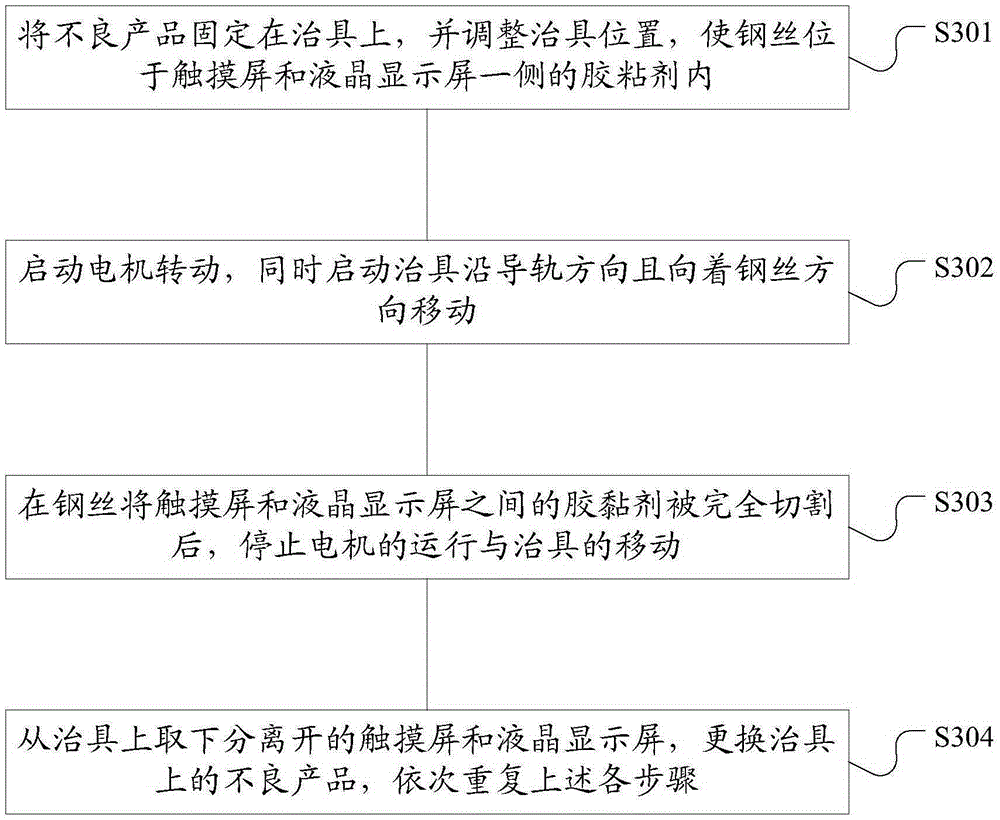

[0072] An embodiment of the present invention provides a method for dismantling a touch screen and a liquid crystal display, which is applied to the dismantling device provided in the previous embodiment, and is used to dismantle defective products that are fixedly connected between the touch screen and the liquid crystal display through an adhesive, Specifically, the process method is as image 3 shown, including the following steps:

[0073] Step S301: Fix the defective product on the jig, and adjust the position of the jig so that the steel wire is located in the adhesive on one side of the touch screen and the liquid crystal display.

[0074] It should be noted that, as known to those skilled in the art, it is necessary to check whether the power of the device is turned on before this. When the power of the device is turned on, adjust the position of the jig on the guide rail so that the steel wire is located between the touch screen and the liquid crystal display. in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com