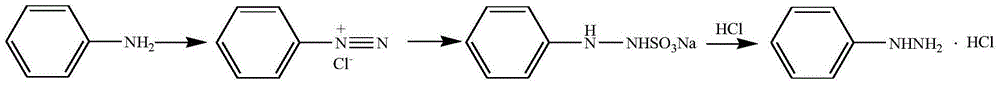

Synthetic method of phenylhydrazine hydrochloride

A technology of phenylhydrazine hydrochloride and synthesis method, which is applied in the field of organic synthesis, can solve problems such as product yield reduction, serious environmental pollution, and nitrogen salt instability, and achieve the effects of easy reaction temperature, simple operation, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The synthetic method of phenylhydrazine hydrochloride:

[0019] In a 1000mL four-necked flask equipped with a mechanical stirrer, a dropping funnel, a reflux condenser and a thermometer, dissolve 93g (1mol) of aniline in 500mL of 2M dilute hydrochloric acid, then add 64g (1.07mol) of urea, stir to dissolve, and heat to reflux 2h, hot filtration, cooling, the filtrate precipitated crystals. The crystals were washed with a small amount of cold water, and the filtrate and washings were refluxed again. Repeat the operation more than three times to obtain crude N-phenylurea. Crude N-phenylurea was recrystallized and dried to obtain 117.6 g of N-phenylurea, yield 86.4%, mp: 145-147°C.

[0020] In a 500mL four-necked flask equipped with a mechanical stirrer, a dropping funnel, a reflux condenser and a thermometer, dissolve 58.5g (0.43mol) of N-phenylurea in ethanol, control the temperature at 15°C, and add dropwise to the solution The ethanol solution containing 32g (0.45mo...

Embodiment 2

[0024] The synthetic method of phenylhydrazine hydrochloride:

[0025] The preparation of N-phenylurea is the same as in Example 1.

[0026] In a 500mL four-neck flask equipped with a mechanical stirrer, a dropping funnel, a reflux condenser and a thermometer, dissolve 58.5g (0.43mol) of phenylurea in methanol, control the temperature at 15°C, and dropwise add 32g of (0.45mol) methanol solution of chlorine gas, after the dropwise addition, continue to react for half an hour. Under the condition of ice-water bath, 86g (2.15mol) NaOH aqueous solution was slowly added dropwise, and the reaction was continued for half an hour after the dropwise addition was completed. Filter, heat and distill off methanol and part of the water, and extract the remaining mixture with toluene. First distill the toluene from the extract, and then distill the fraction at 120-125°C / 10mmHg under reduced pressure to obtain phenylhydrazine. The obtained phenylhydrazine was added dropwise to hydrochlori...

Embodiment 3

[0030] The synthetic method of phenylhydrazine hydrochloride:

[0031] The preparation of N-phenylurea is the same as in Example 1.

[0032] In a 500mL four-necked flask equipped with a mechanical stirrer, a dropping funnel, a reflux condenser and a thermometer, dissolve 58.5g (0.43mol) of phenylurea in ethanol, control the temperature at 15°C, and dropwise add 62g of (0.86mol) ethanol solution of chlorine gas, after the dropwise addition, continue to react for half an hour. Under the condition of ice-water bath, 86g (2.15mol) NaOH aqueous solution was slowly added dropwise, and the reaction was continued for half an hour after the dropwise addition was completed. Filter, heat and distill off ethanol and part of the water, and extract the remaining mixture with toluene. First distill off the toluene from the extract, and then distill off the fraction at 120-125°C / 10mmHg under reduced pressure to obtain phenylhydrazine. The obtained phenylhydrazine was added dropwise to hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com