Roof Negative Pressure Exhaust Configuration

An exhaust port and negative pressure technology, applied in vertical pipes, building components, buildings, etc., can solve problems such as energy consumption, noise, vibration, etc., and achieve the effects of simple body, easy maintenance, and various installation forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

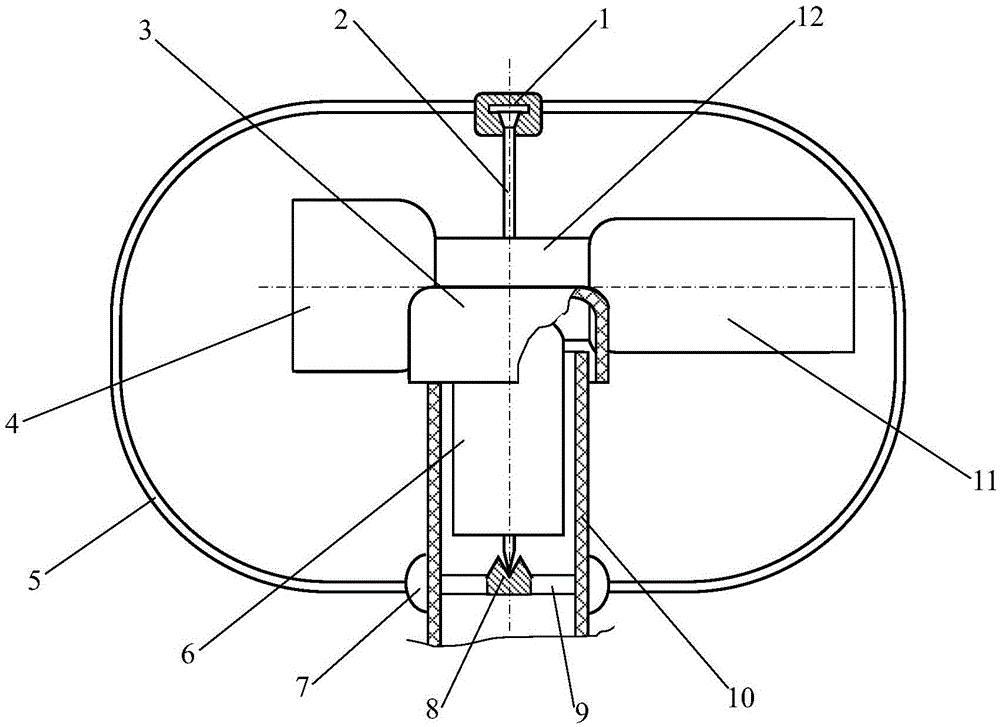

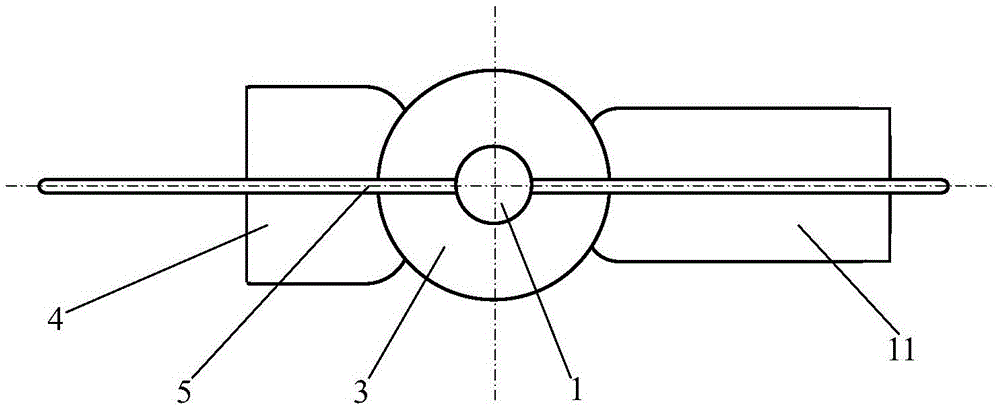

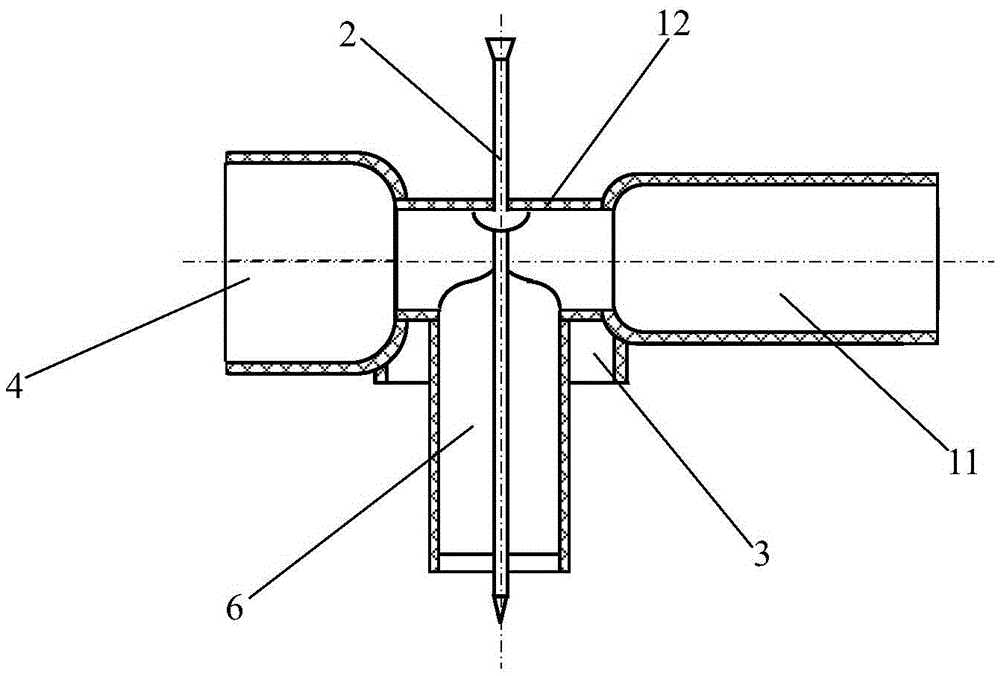

[0015] exist figure 1 , 2 In the roof negative pressure exhaust outlet configuration view shown in and 4: the roof negative pressure exhaust outlet configuration includes the roof negative pressure exhaust outlet device and frame 5, the roof pipe 10, and the roof negative pressure exhaust outlet device It is installed on the roof pipe 10 through the framework 5 . The roof negative pressure exhaust port device is composed of mandrel 2, cover 3, front windward pipe 4, lower vertical pipe 6, support beam 9, rear tailpipe 11 and neck pipe 12. The frame 5 is composed of an upper bearing structure 1 , a lower bearing structure 8 and a hoop seat structure 7 .

[0016] exist figure 1 The front view and figure 2 In the top view of the configuration of negative pressure exhaust outlets on the roof shown: the upper bearing structure 1 is fixedly installed in the center of the top section of the frame 5 of the elliptical ring structure, and the upper bearing structure 1 is rolled and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com