Semi-active vibration isolation system

A semi-active and workbench technology, applied in the direction of non-rotational vibration suppression, etc., can solve the problems of limited vibration isolation performance, no vibration isolation performance, and decreased production efficiency, so as to reduce shaking time, reduce resonance frequency, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

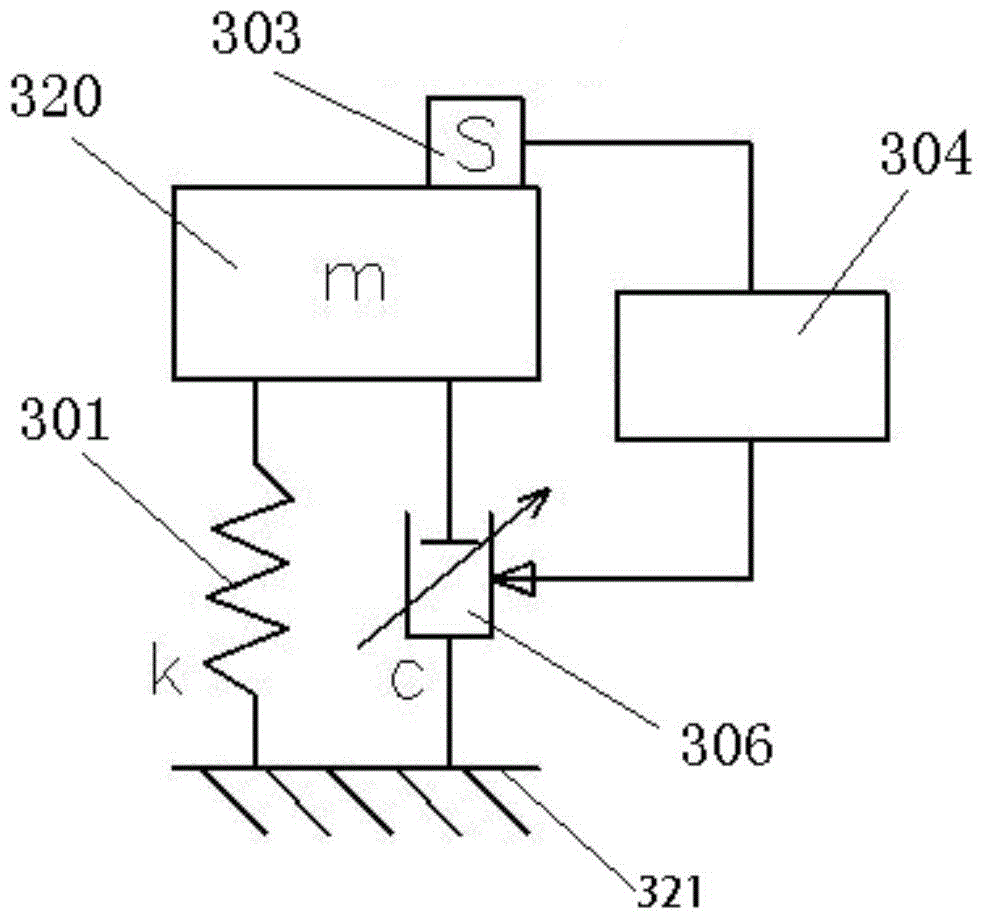

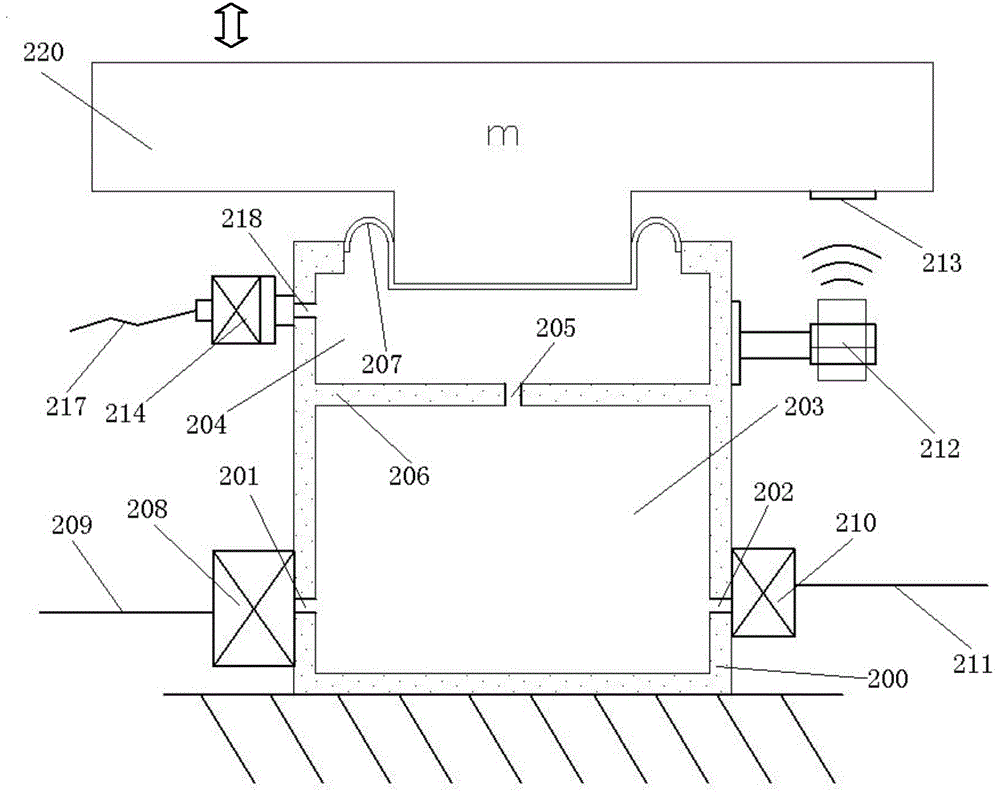

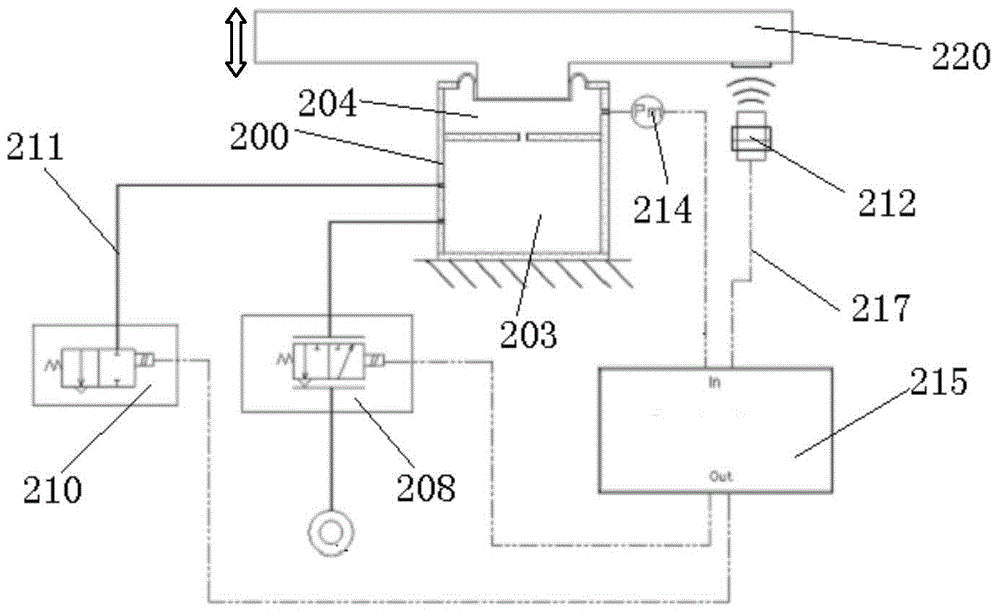

[0024] A semi-active vibration elimination system, including a base plate and an upper worktable, a vibration isolation mechanism is provided between the base plate 321 and the upper worktable 320, and the vibration elimination mechanism includes a spring 301 and a buffer device, and the buffer The device is connected with the sensor 303 placed on the upper workbench through the controller 304, and the buffer device adopts an adjustable buffer device 306, and forms an integral vibration elimination system with the controller, sensor and spring. The vibration-removing mechanism includes an elastic module body 200, the elastic module body is composed of a hollow buffer chamber 203 and a spring chamber 204, a rubber diaphragm 207 is arranged on the top of the spring chamber, and the rubber diaphragm and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com