Double-clutch transmission with long idler shaft

A dual-clutch, idler shaft technology, applied to vehicle gearboxes, geared components, gear transmissions, etc., can solve the problems of difficulty in increasing the ratio of teeth, low economy and power, and high engine efficiency loss. Achieve the effects of increased balance, convenient design of the number of teeth, and small loss of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

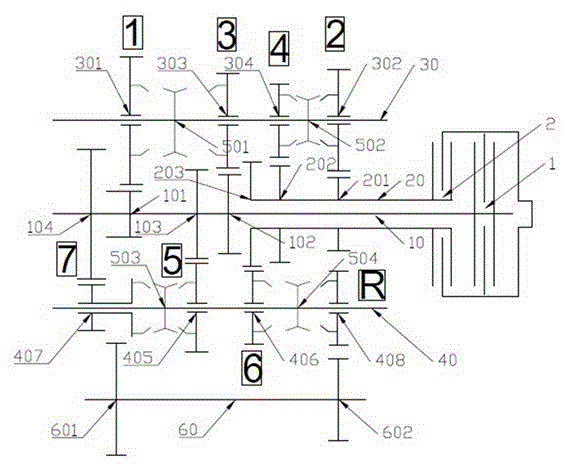

[0031] The present invention provides a dual clutch gearbox with a long idler shaft, such as figure 1 As shown, a dual-clutch gearbox with a long idler shaft includes: a first clutch 1, a second clutch 2 arranged in a clutch housing, and a first output shaft 30 and a second clutch protruding from the gearbox housing. Two output shafts 40.

[0032] The first clutch 1 is connected with the first input shaft 10, the second clutch 2 is connected with the second input shaft 20 and the second input shaft 20 is sleeved on the first input shaft 10, and the output shaft is parallel to the input shaft and located on both sides of the input shaft. side. The first clutch 1 and the second clutch 2 selectively transmit engine torque to the first output shaft 10 and the second output shaft 20 .

[0033] A dual-clutch transmission with a long idler shaft has seven forward gears and one reverse. The design of the seven-speed gearbox structure makes the engine have better economy and power, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com