Ultra-wear-resistant control valve

A valve control, super wear-resistant technology, used in sliding valves, valve details, valve devices, etc., can solve problems such as valve body extrusion and rupture, valve switching, adjustment failure, and inability to solve the problem of high abrasive materials on valve wear, etc. Achieve the effect of increasing life and preventing valve damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

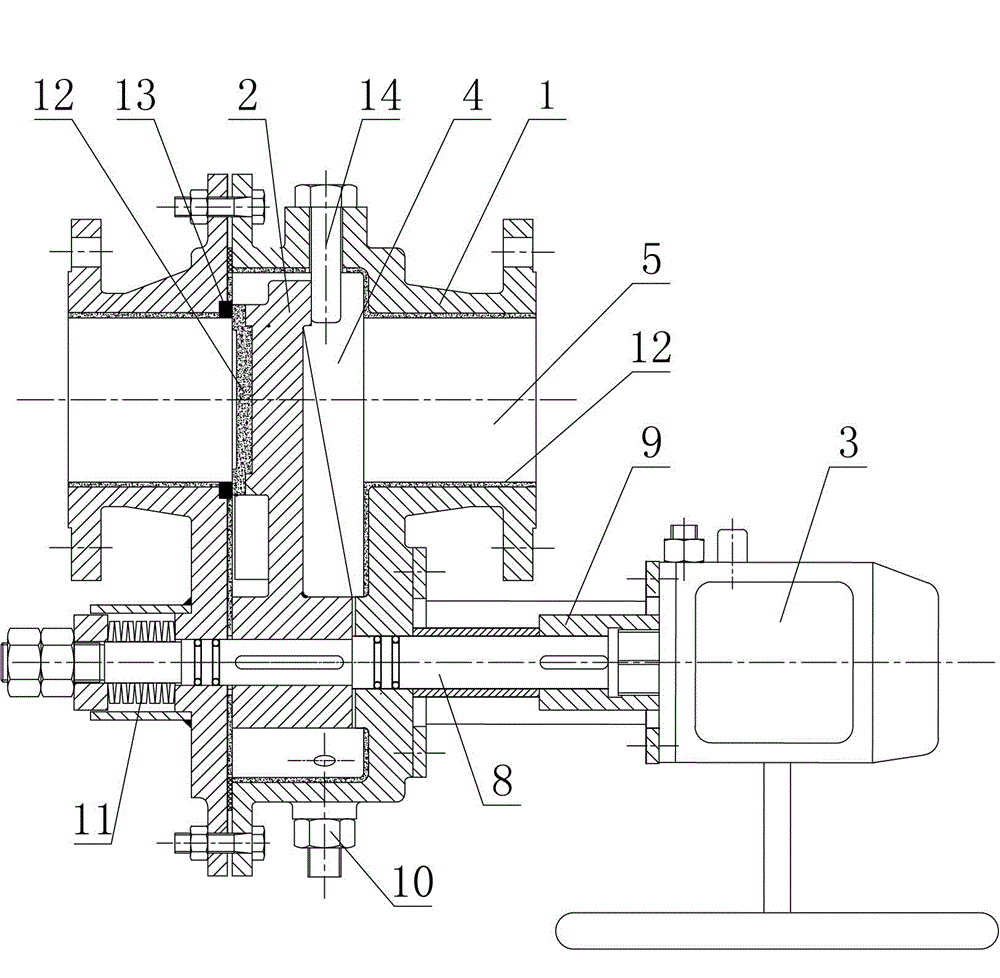

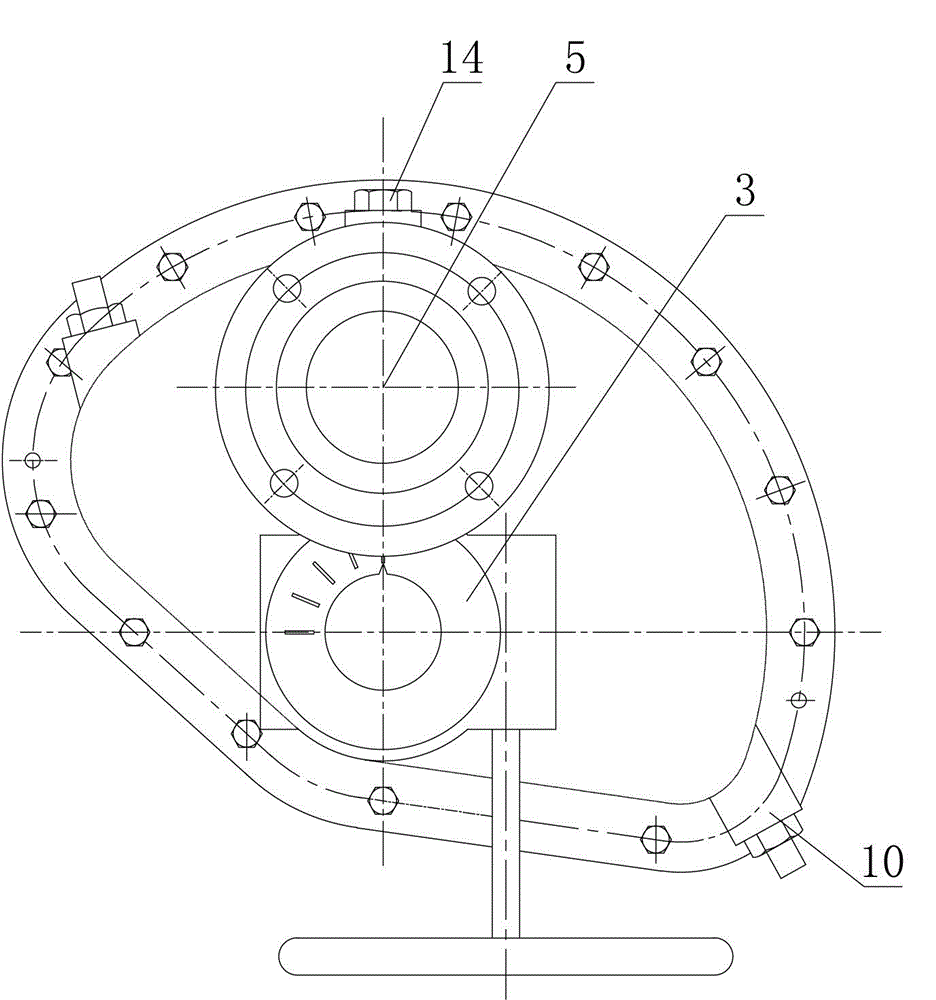

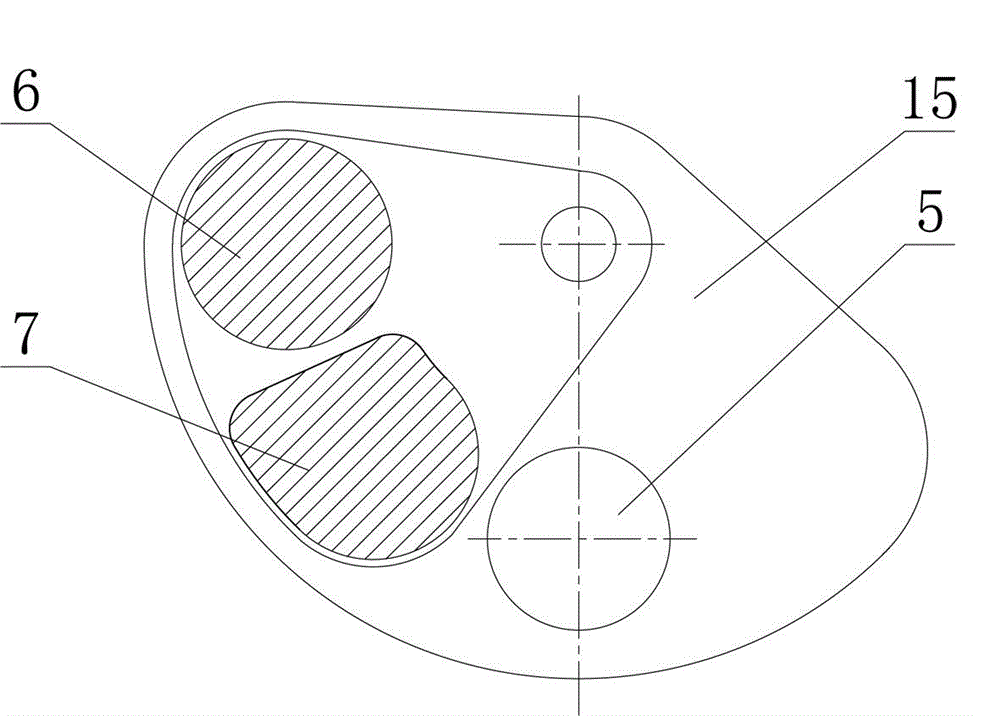

[0024] Such as Figure 1-5 As shown, a super wear-resistant control valve described in the embodiment of the present invention mainly includes a valve body 1, a valve core 2 and an actuator 3, the valve body mainly includes a valve cavity 4 and a medium flow channel 5, and the valve core 2 is placed In the valve cavity 4, the actuator 3 is connected with the valve core 2 and controls the rotation of the valve core 2. The valve core 2 is provided with a sealing body 6 and an adjusting body 7. The sealing body 6 and the adjusting body 7 are arranged separately. When the valve core 2 rotates, The sealing body 6 can be used to seal the medium flow channel 5, and the regulating body 7 can be used to regulate the flow rate of the medium in the medium flow channel 5. The thickness of 12 is greater than the thickness of the tungsten carbide coating 12 on the sealing body, so that the abrasion resistance of the adjusting body 7 is higher than that of the sealing body 6 .

[0025] In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com