System and method for testing rock damage and permeability under coupling effect of temperature stress and circumferential seepage

A technology of temperature stress and penetration testing, which is applied in the direction of applying stable tension/pressure to test material strength, permeability/surface area analysis, and measuring devices, etc. It can solve the problems of uneven test performance, stagnation, and no uniform standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

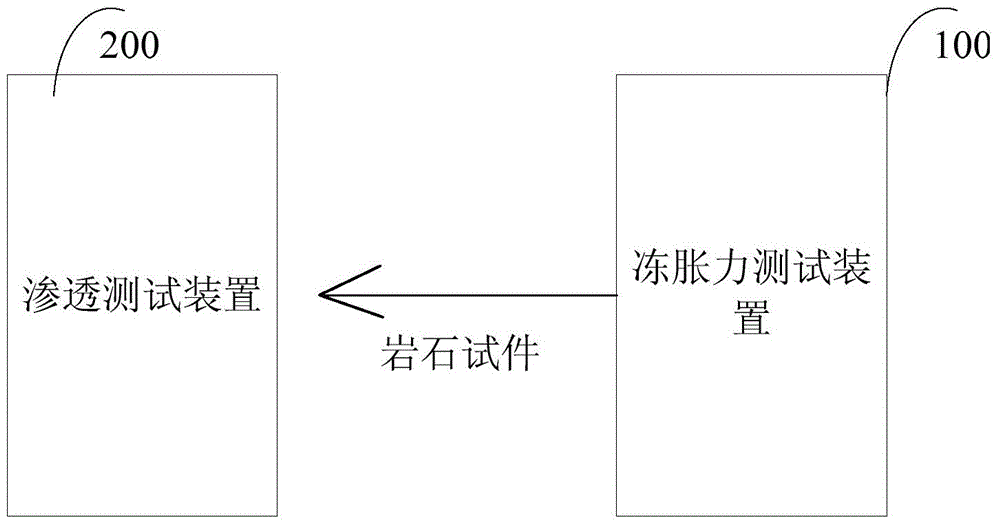

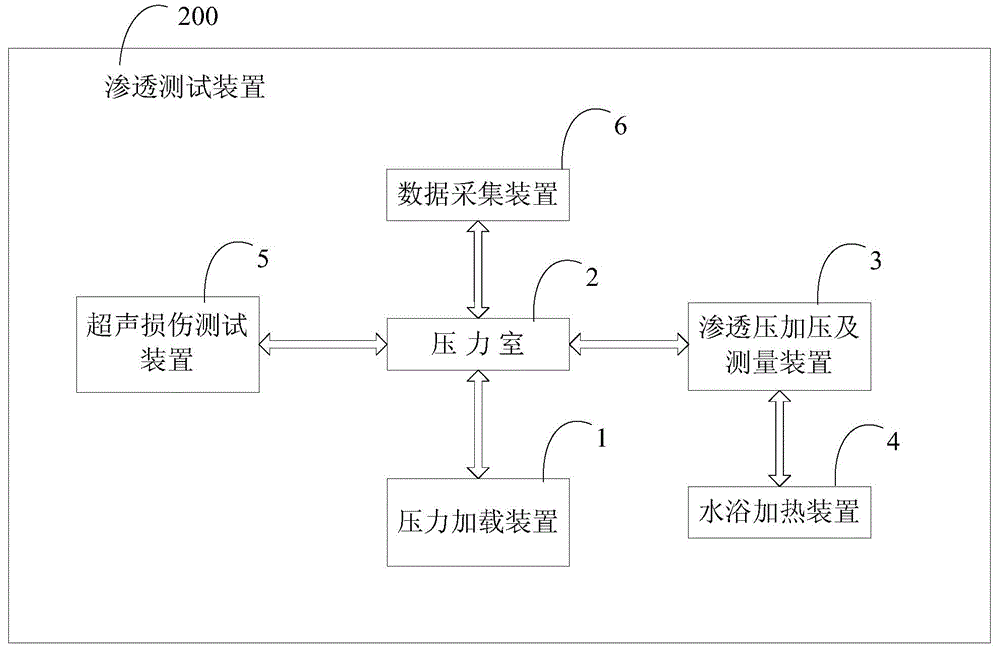

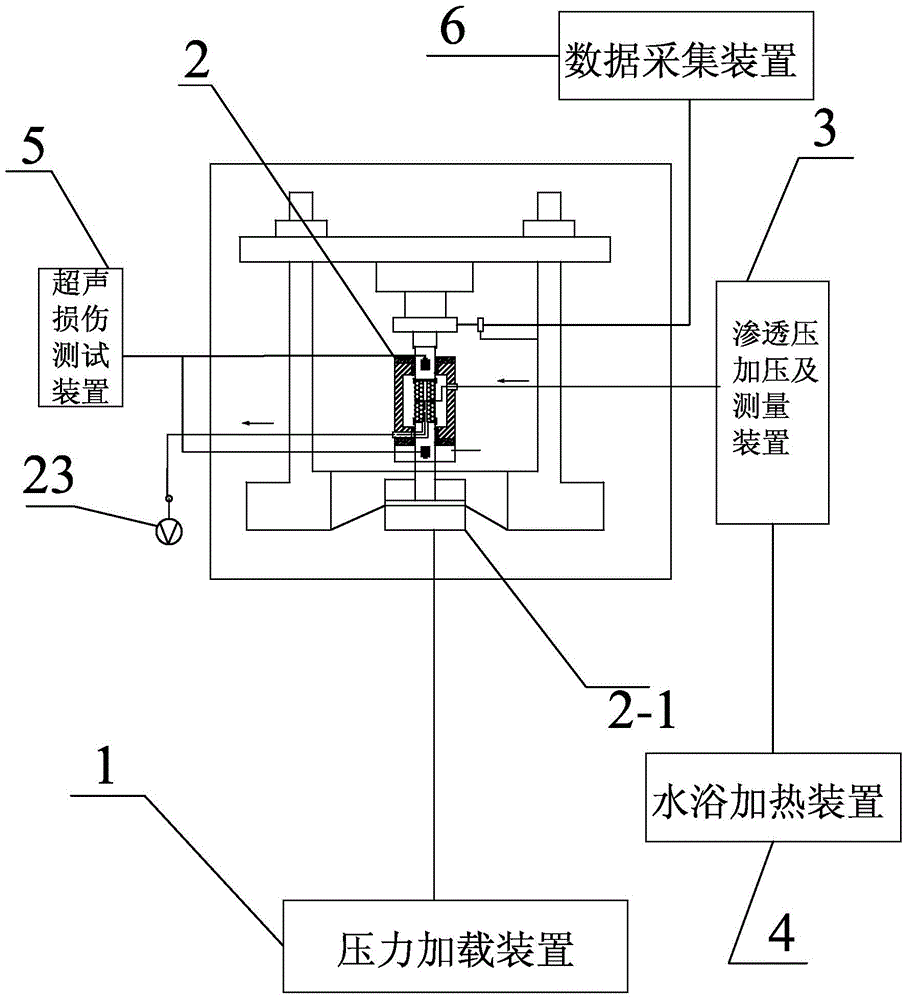

[0041] Embodiment: The testing process of the rock damage and penetration testing system is as follows: firstly, the rock test piece is processed into a hollow structure matching the device shape of the system, the rock test piece is made into different forms of special crack combinations, and the rock test piece The parts are repeatedly frozen and thawed in the frost heaving force testing device 100, and the magnitude of the frost heaving force is measured by the load cell of the device. Then the rock specimen is taken out from the frost heaving force testing device 100, put into the pressure chamber 2 in the penetration testing device 200, and the pressure chamber 2 is ensured to be sealed. Use the pressure loading device 1 to raise the pressure chamber 2 to a certain height to ensure that the rock specimen is sealed in the pressure chamber 2, clear the readings of the load cell in the pressure chamber 2, and set the ultrasonic probe I12-1 and ultrasonic probe II12-2 to zero....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com