Automatic batch tracing method of solar cells

A solar cell, automatic technology, applied in circuits, electrical components, instruments, etc., can solve the problems of increasing labor costs and increasing the risk of mixed batches, and achieve the effect of reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail through the following embodiments in conjunction with the accompanying drawings.

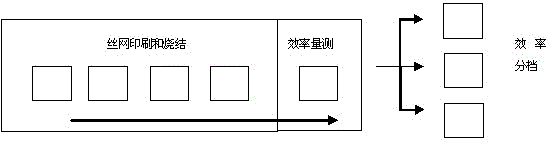

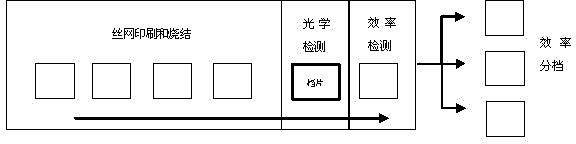

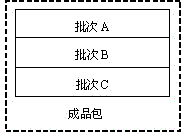

[0013] Such as figure 2 As shown, the automatic batch tracking method of solar cells: the solar cells obtained after screen-printing electrodes by screen printing machine and sintering are tested for efficiency through a sorting machine and enter the finished product package. There are files between different batches of solar cells. The sorting machine is equipped with an automatic optical detection lens. The automatic optical detection lens is connected to the sorting machine and the screen printing machine. When the automatic optical detection lens detects the file, the batch is automatically switched; through system integration, the batch is switched The data can be automatically linked with the finished product package number, and the batch and manufacturing time contained in each finished product package are stored in the sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com