Probe moving position control device for ultrasonic flaw detection of wheel set and usage method

A technology for probe movement and control devices, which is applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves. It can solve problems such as increased moving range, crack detection, and incomplete coverage, and achieves flexible positioning and adjustment. , avoid offset, reduce the effect of scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

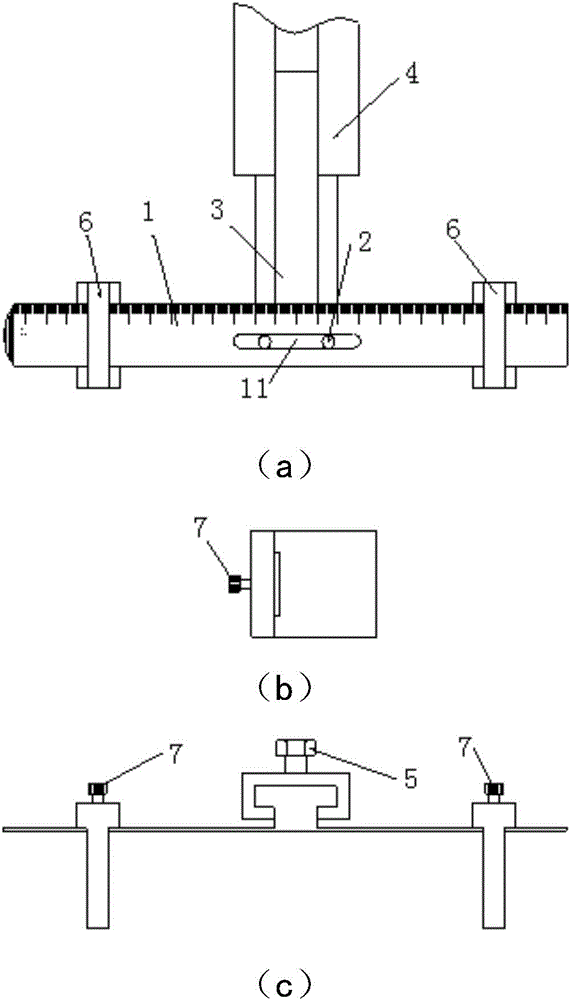

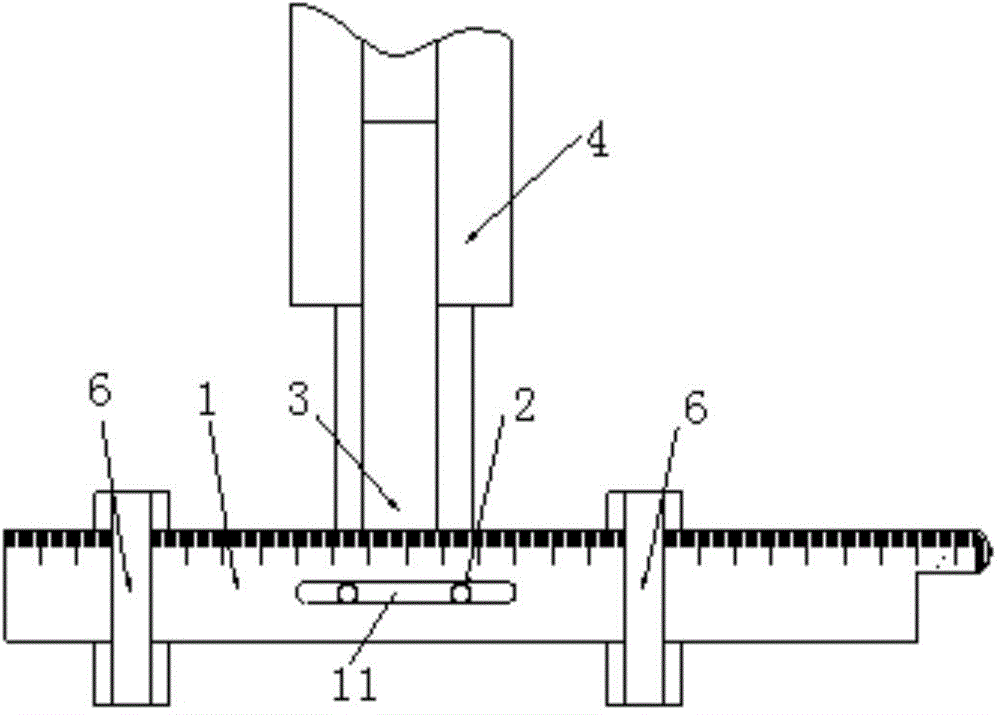

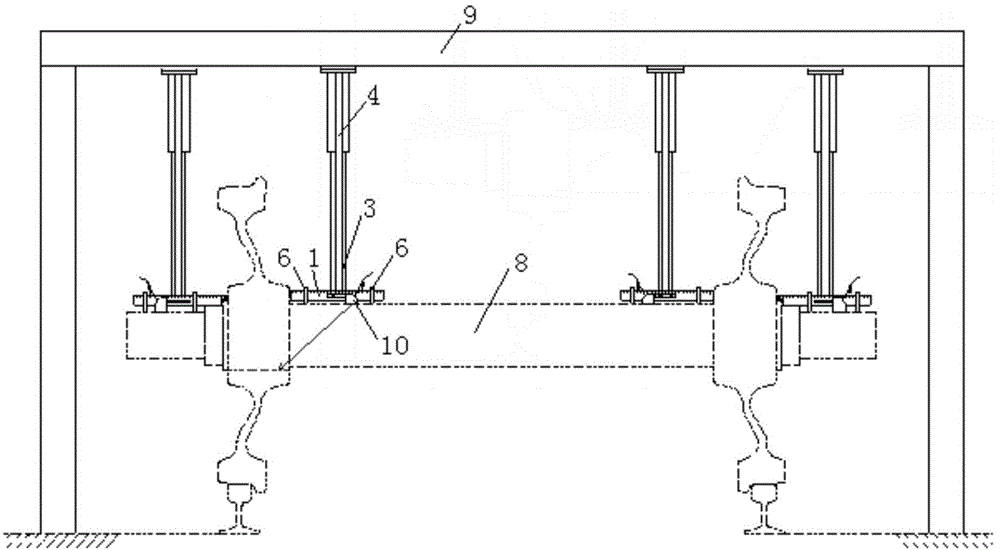

[0017] Such as figure 1 As shown, the probe moving position control device for wheel set ultrasonic flaw detection of the present invention includes a scaled substrate 1, more than one bolt nut 2, a dovetail slide bar 3, a dovetail chute 4, a fastening bolt 5, two Limiting moving plate 6 and two fastening screws 7. There is a long hole 11 horizontally in the middle of the base plate 1. The bolts and nuts 2 pass through the long hole 11 to fix one end of the dovetail slider 3 on the base plate 1, and the other end of the dovetail slider 3 is slid in the dovetail chute 4. , so that the connection position between the dovetail slide bar 3 and the dovetail chute 4 can be adjusted, and after the connection position is determined, the dovetail slide bar 3 is fixed in the dovetail chute 4 by fastening bolts 5 . Two limit moving plates 6 are respectively in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com