Intelligent terminal used for metal damage detection

An intelligent terminal, damage detection technology, applied in the direction of material magnetic variables, etc., can solve the problems of missed detection, the speed and position of human hand movement cannot be accurately controlled, etc., and achieve the effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the drawings:

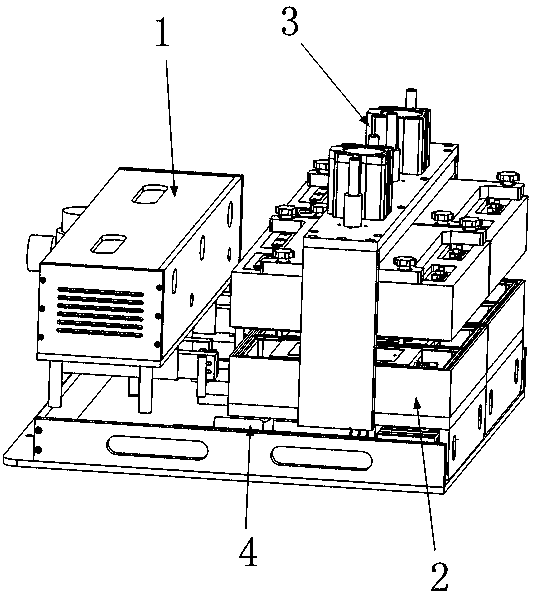

[0017] Such as figure 1 As shown, the smart terminal includes: a processing mechanism 1, a detection mechanism 2, and a driving mechanism 3. The metal 4 to be tested is placed in the detection mechanism 2. The processing mechanism 1 is used to receive the test data sent by the detection mechanism 2 and analyze and process the data. The driving mechanism 3 can optionally form an electrical connection with the detection mechanism 2 for driving or The detection operation of the detection mechanism 2 is stopped.

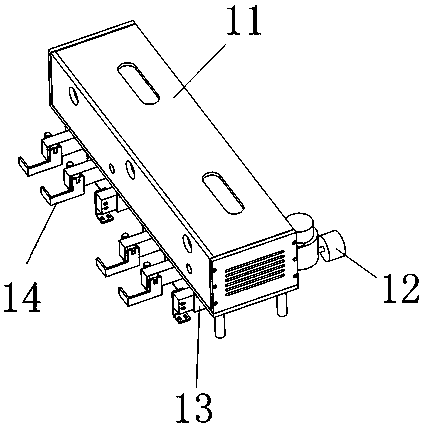

[0018] Such as figure 2 As shown, the processing mechanism 1 includes: an electric control box 11, a power supply 12, a connecting cylinder 13 and a connecting metal sheet 14. The components in the electric control box 11 include a single-chip microcomputer, an amplifier, an A / D converter, and a voltage comparator. The working principle is the same as that of the data processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com