Trash removal device on sugarcane harvester

A harvester and sugarcane technology, which is applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of reducing sugarcane work efficiency, affecting sugarcane processing work, and easy blocking of cutting devices. Transfer and maintenance, smooth effect of impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

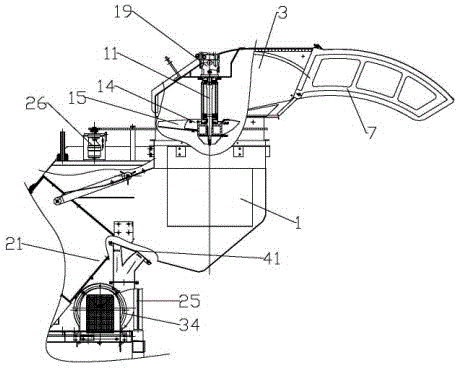

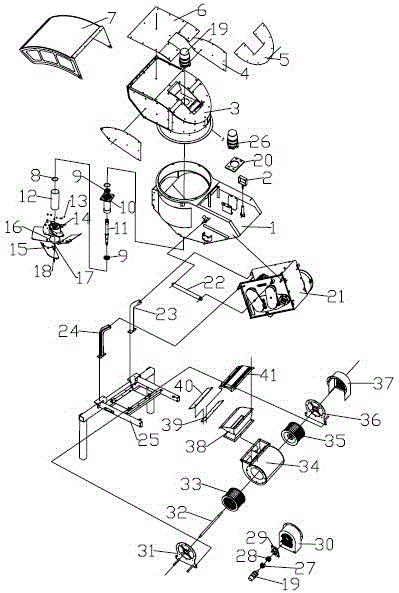

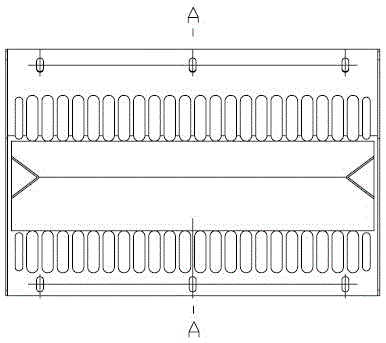

[0021] Below in conjunction with accompanying drawing, the miscellaneous device on the sugarcane harvester of the present invention is further described:

[0022] Such as figure 1 , figure 2 , shows the parts related to the miscellaneous removal device on the sugarcane harvester of the present invention, namely the fan mounting base 1, the upper fan oil pipe frame 2, the drive box 3, the wear plate 4, the top wear plate 5, the outlet upper plate wear plate 6. Outlet cover 7, snap ring 8, deep groove bearing 9, upper fan transmission cylinder 10, fan shaft 11, external delivery cylinder 12, nut 13, fan blade seat 14, fan blade 15, dust cover 16, gasket 17 , bolt 18, upper fan motor 19, swing motor mount 20, three-stage conveying 21, hydraulic cylinder 22, bracket left 23, bracket right 24, frame 25, air outlet swing motor 26, motor shaft coupling 27, lower Fan shaft coupling 28, motor mounting plate 29, left wheel cover 30, left support plate welding 31, bellows shaft 32, le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com