Core machine

A core making machine and core box technology, applied in the direction of cores, molding machines, manufacturing tools, etc., can solve the problems of easy damage of vacuum pipelines and seals, manual installation and disassembly maintenance, failure of installation and fixation, etc., to achieve convenient replacement and maintenance, The effect of improving synchronization performance and simplifying installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

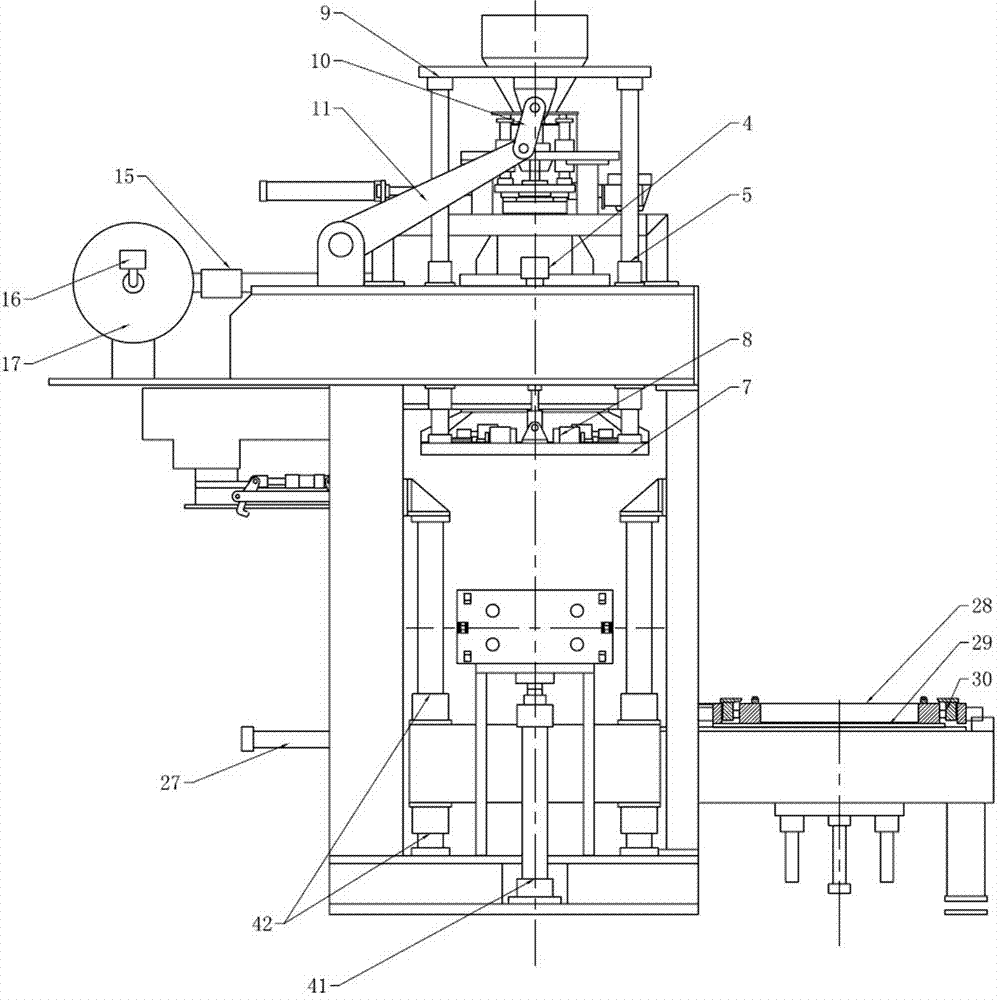

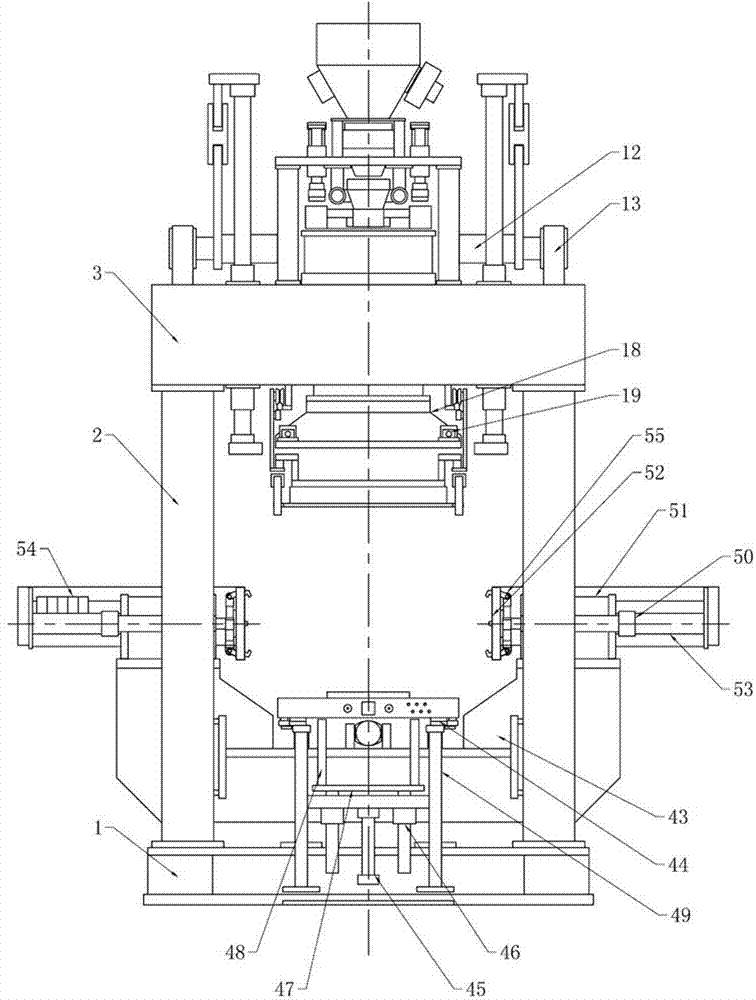

[0025] Embodiment one: see Figure 1 to Figure 2 As shown, the present invention provides a cold box core making machine which is mainly suitable for the production mode of manual coring. Through the visual human-computer interaction interface, manual / automatic operation can be performed, which is very flexible and versatile; it is suitable for 2~ The 6-box core box mold can be equipped with multiple sets of pneumatic or hydraulic movable blocks at the same time to meet the needs of producing various complex sand cores. The mold loading is mainly carried out by manual hoisting at the front side of the equipment, and a superimposed step-by-step mold loading method is adopted, and the loading and unloading process is completed step by step.

[0026] The standard model of the cold box core making machine can have different series of products from 20L to 150L to choose from. The sand shooting area can reach up to 1800mm front and rear, and 1200mm left and right. The maximum weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com