Assembling and disassembling tool and method of coupler

A coupling, assembly and disassembly technology, used in manufacturing tools, metal processing, metal processing equipment, etc., can solve problems such as tools that do not involve coupling assembly and disassembly, and achieve safe assembly and disassembly, good technical effects, and economical The effect of removing physical labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

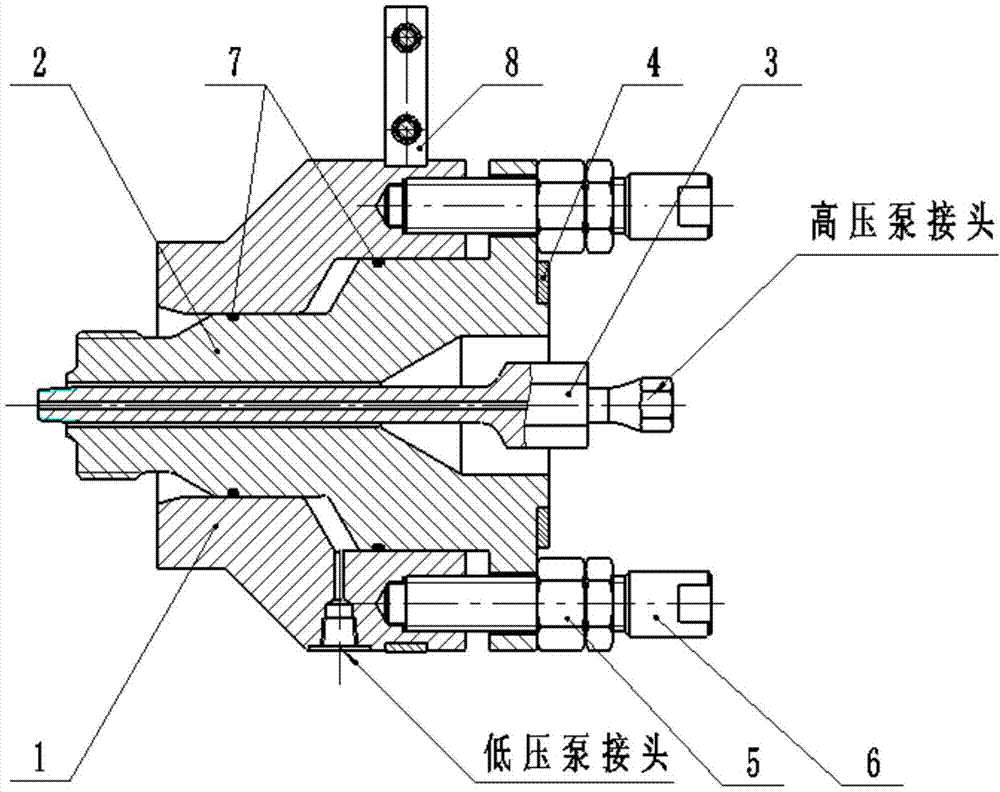

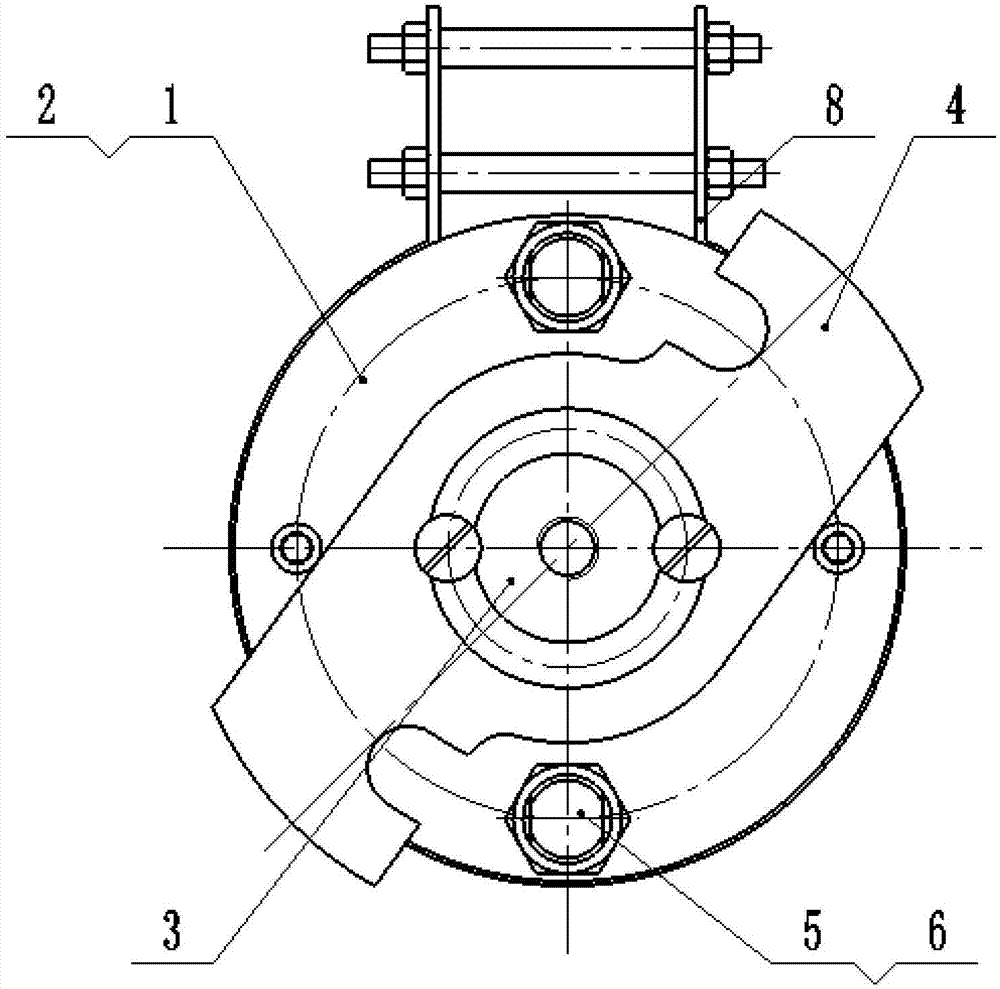

[0031] Embodiment 1 Assembly and disassembly tool for shaft couplings with a diameter of 70 to 80 mm

[0032] The specifications of the cylinder body are: the diameter of the front section is 90mm; the diameter of the back section is 155mm; the total length is 125mm; mm; thread Z3 / 8 at the front end of the hydraulic pipe, the outer diameter of the middle section is 17.6 mm, the inner diameter is 4 mm, and the length is 310 mm. The screw is M18×1.5, and the length is 130 mm.

Embodiment 2

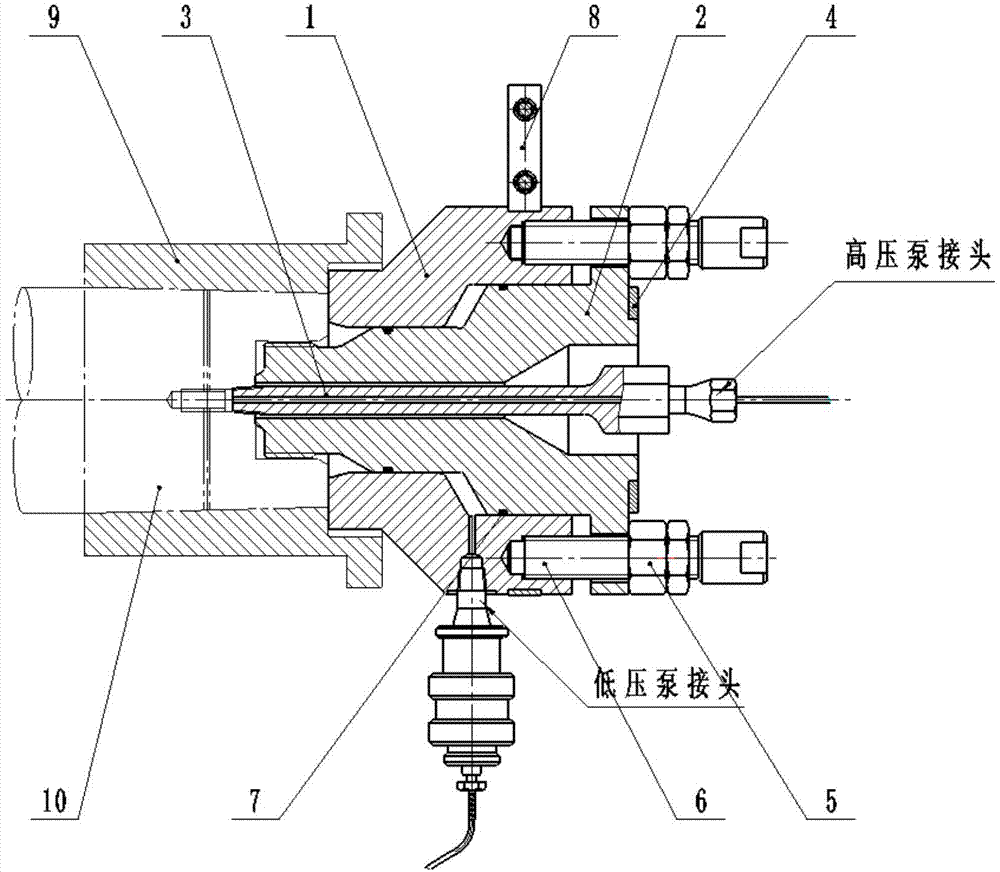

[0033] Embodiment 2 Assembly and disassembly tools for shaft couplings with a diameter of 90 mm

[0034] The specifications of the cylinder body are: the diameter of the front section is 120mm; the diameter of the rear section is 155mm; the total length is 175mm; the specification of the piston is: the thread of the front section is M36×3, the diameter of the second section is 37mm, the diameter of the third section is 45mm, and the diameter of the disc is 155mm ; The thread of the front end of the hydraulic pipe is Z3 / 8, the inner diameter is 4 mm, and the length is 17.5 mm. The screw M18×105 is 130 mm in length.

Embodiment 3

[0035] Embodiment 3 Assembly and disassembly tools for shaft couplings with a diameter of 100 to 110 mm

[0036] The specifications of the cylinder body are: the diameter of the front section is 120mm; the diameter of the rear section is 155mm; the total length is 175mm; the specification of the piston is: the front thread M36×3, the diameter of the second section is 49mm, the diameter of the third section is 57mm, and the diameter of the disc is 155mm ; Hydraulic front thread Z3 / 8, inner diameter 4 mm, outer diameter 17.5 mm, length 310 mm; screw M10×1.5, length 130 mm.

[0037] Since the centrifugal compressor and the power machine connected to it are quite heavy, it is extremely difficult to assemble and disassemble manually, which is labor-intensive and labor-intensive, and it is easy to cause coupling deformation, or there is a certain stress due to the misalignment between the compressor and the power machine. These will make the compressor work abnormally. The above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com