A pre-branched flexible mineral composite insulated fireproof cable and its manufacturing method

A composite insulation and branch cable technology, applied in the direction of insulated cables, cable/conductor manufacturing, insulated conductors, etc., can solve the problems that restrict the promotion and application of fireproof cables, decrease the fireproof performance of cables, and unstable electrical performance, and achieve good sealing, The effect of stable electrical performance and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

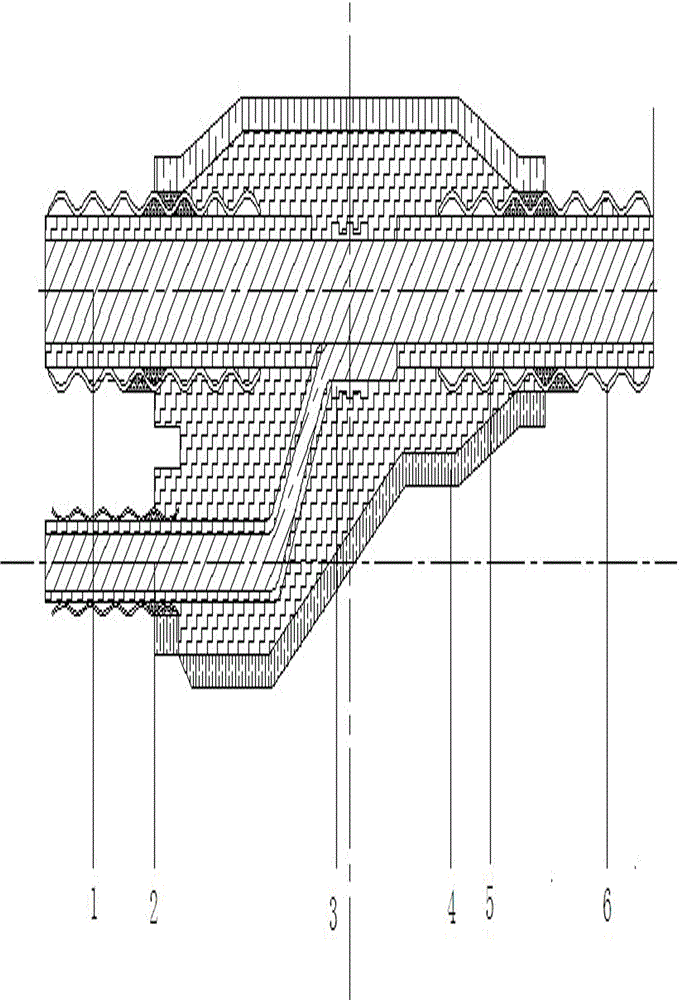

[0057] according to figure 1 , 2 , 5 and 6, a single-core grafted single-core pre-branched flexible mineral composite insulated fireproof cable and a manufacturing method thereof, the steps are as follows:

[0058] (1) According to the diameter requirements of the copper single wire, the copper rod is drawn into a round single wire with a diameter of 0.4mm through the continuous annealing and wire drawing process of a multi-channel circular hole drawing die;

[0059] (2) According to the requirements of the conductor structure, different annealed round copper single wires are tightly twisted on the stranding machine to complete the conductive wire core;

[0060] (3) The conductive wire core is first wrapped with 3 layers of synthetic mica tape, and then extruded or wrapped with a specified thickness of ceramic silicone rubber to complete the mineral composite insulating layer;

[0061] (4) Complete the copper sheath armoring of the main cable core and the branch cable core t...

Embodiment 2

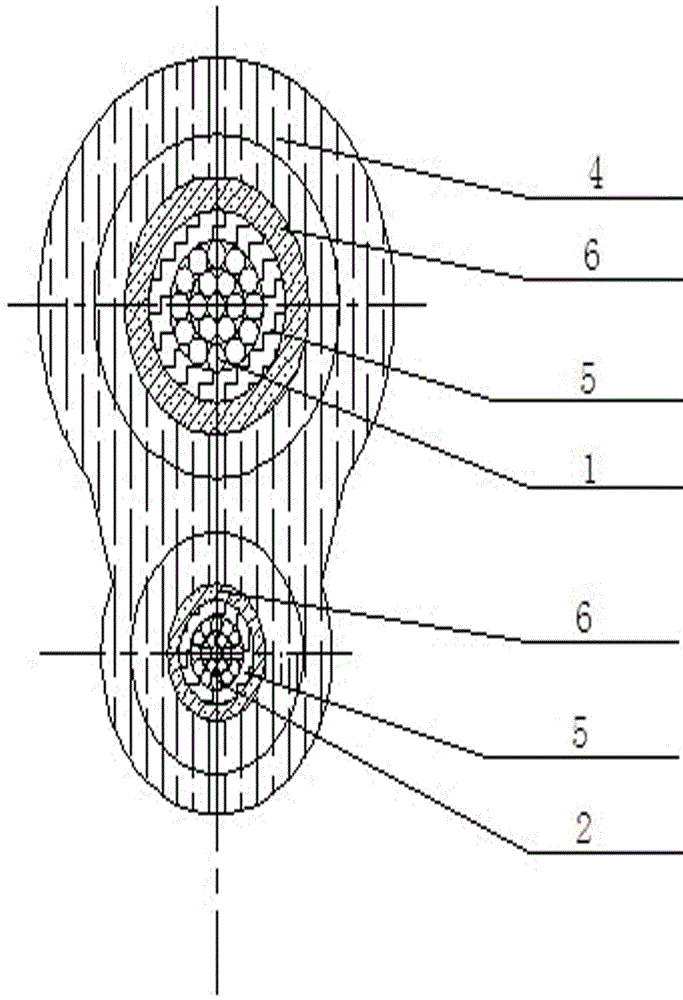

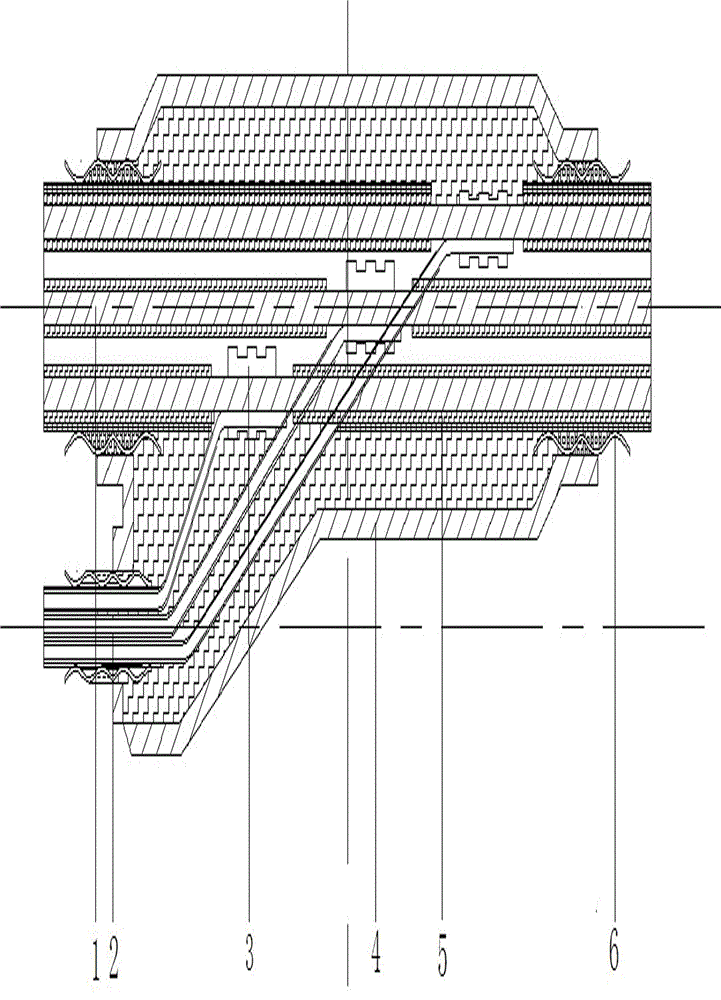

[0069] according to image 3 , 4 , 5 and 6, a method for making a multi-core grafted multi-core pre-branched flexible mineral composite insulated fireproof cable, the steps are as follows:

[0070] (1) According to the diameter requirements of the copper single wire, the copper rod is drawn into a round single wire with a diameter of 4mm through the continuous annealing and wire drawing process of a multi-channel circular hole drawing die;

[0071] (2) According to the requirements of the conductor structure, different numbers of annealed round copper single wires are tightly twisted on the stranding machine to complete the conductive wire core;

[0072] (1) The conductive wire core is first wrapped with 4 layers of synthetic mica tape, and then extruded or wrapped with a specified thickness of ceramic silicone rubber to complete the mineral composite insulating layer;

[0073] (2) Insulated cores, filling materials and lining tapes are cabled by a cable forming machine;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com