A negative pressure airtight greenhouse applied to the repair of sites with irritating odor and its construction method and repair method

A pungent odor and site restoration technology, applied in the restoration of contaminated soil, etc., can solve the problems of increasing project management costs and safety risks, affecting construction efficiency and applicability, and high turnover cost, so as to achieve safe and reliable wind and snow protection, Disassembly loss and transportation costs are reduced, and assembly and disassembly are simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

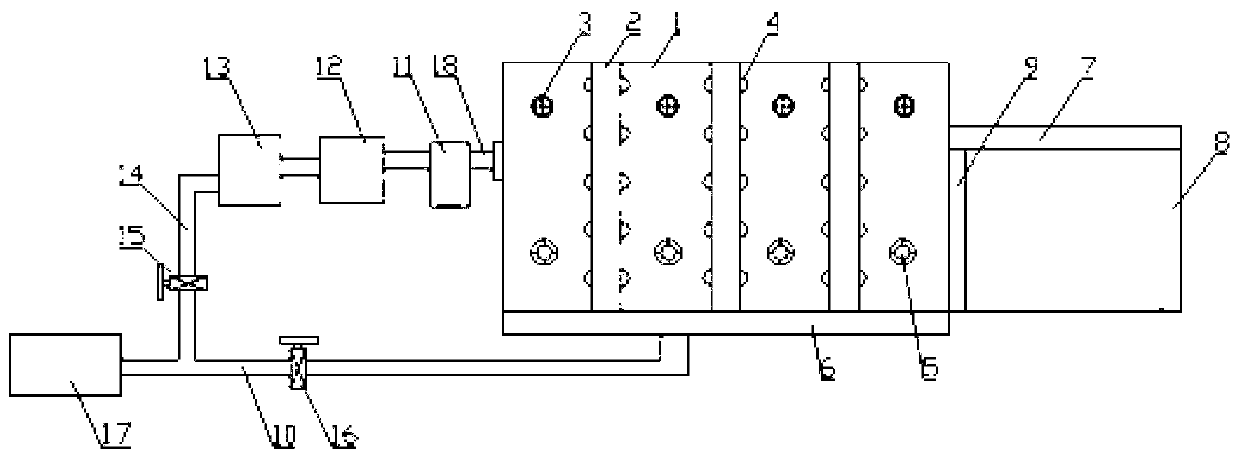

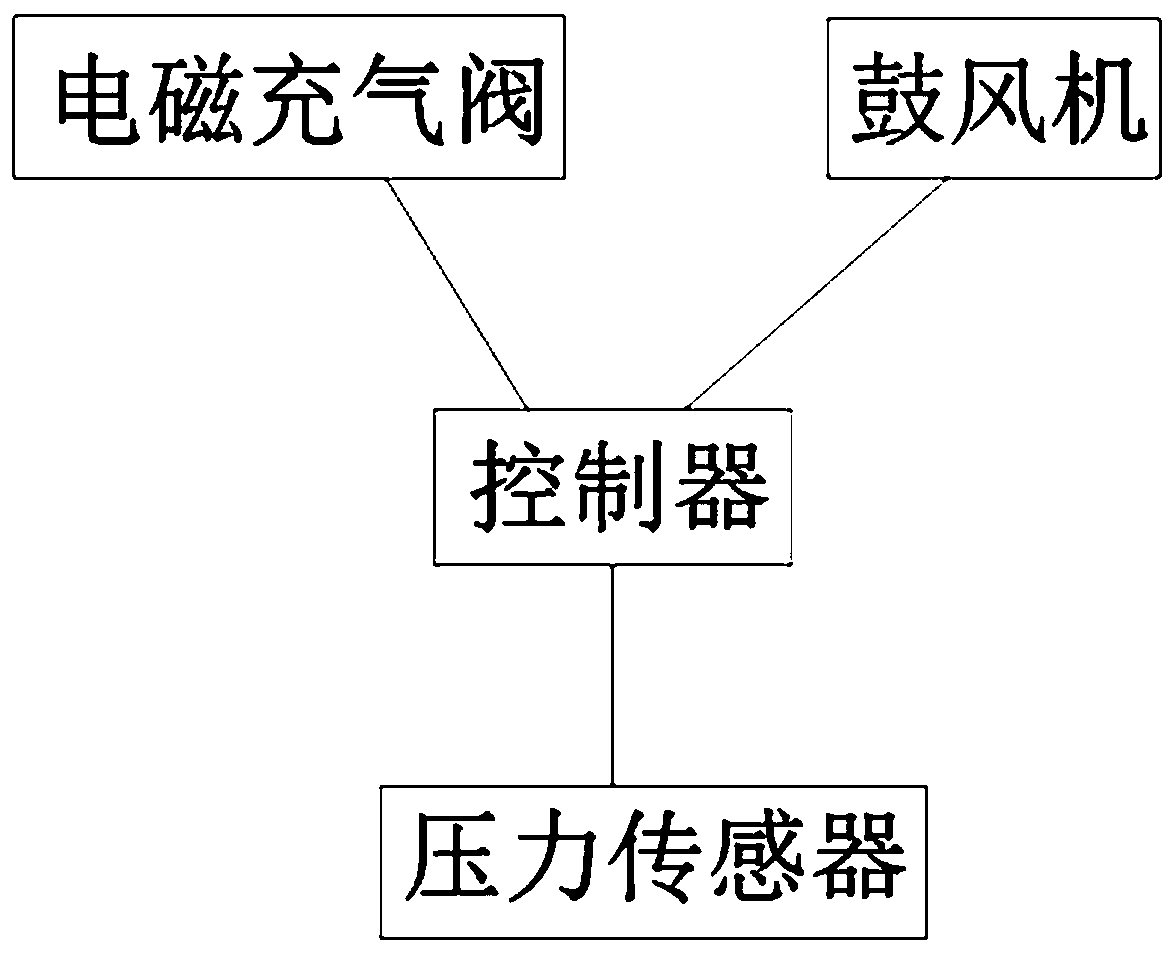

[0036] Such as Figure 1-Figure 3As shown, a negative pressure airtight greenhouse and its construction method applied to site restoration with irritating odors, including an airbag shed body, a vehicle corridor 7 arranged on one side of the airbag shed body, arranged on the side of the airbag shed body and located at the side of the airbag shed The feed door 9 between the shed body and the vehicle corridor 7, the vehicle entrance and exit door 8 arranged on the outside of the vehicle corridor 7 and corresponding to the feed door 9, the exhaust gas treatment system arranged on the other side of the airbag shed body, and one end connected to the The return air pipeline 10 on the exhaust gas treatment system; the bottom of the airbag shed is provided with a grid plate 6; the two sides of the airbag shed are respectively provided with side airbag rows that are airtightly connected with the airbag shed; The other end of the air duct 10 is disposed below the mesh grid plate 6 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com