Tritium gas purified tail gas storage and tinning system

A tritium gas introduction system technology, applied in inorganic chemistry, chemical instruments and methods, non-metallic elements, etc., can solve the problems of high cost and low tritium recovery rate, achieve rapid separation, reduce the risk of tritium leakage, and operate safely Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated in conjunction with specific implementation methods and accompanying drawings of the description.

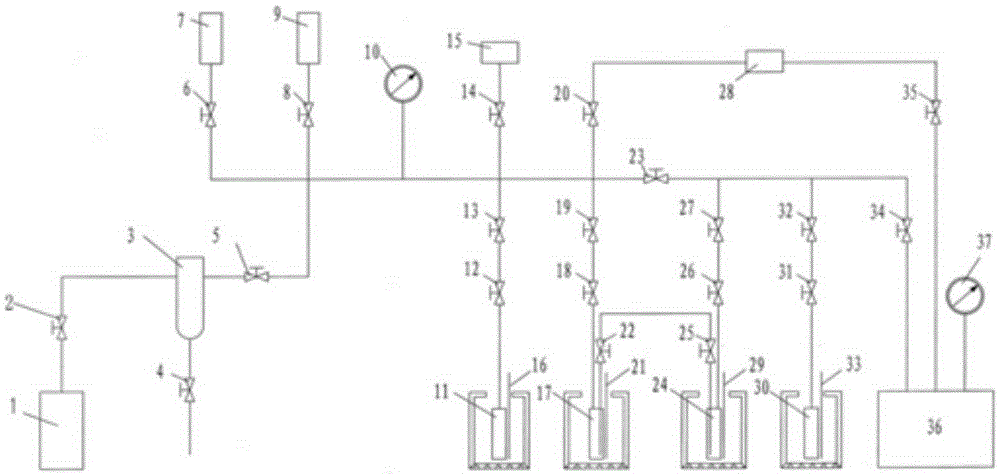

[0027] A tritium gas purification system, such as figure 1 shown. The system includes a tritium gas introduction system, a circulation separation system, and an exhaust gas monitoring system that can be connected or disconnected through a valve; the tritium gas introduction system includes a vacuum pump 1, a cold trap 3, buffer bottles 7, 9, a vacuum gauge 15 and a The purified tritium-uranium powder bottle 11, wherein the tritium-uranium powder bottle 11 to be purified provides tritium gas for the entire purification system, the vacuum pump 1 is connected to the cold trap 3 through pipelines, and the pipelines drawn from the cold trap 3 are respectively connected to the buffer bottle through four links 7, 9, the vacuum gauge 15, the detritiated uranium powder bottle 11 to be purified and the circulation separation system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com