Thermal-fluid-solid coupling CT triaxial pressure chamber lifting device for loaded coal and rock mass

A triaxial pressure, thermal fluid solid technology, applied in the direction of measuring device, using stable tension/pressure test material strength, suspension and porous material analysis, etc., can solve the problem of low strength-density ratio, low stress and difficult matching Structure and other issues, to achieve the effect of simple structure, convenient operation, low cost of manufacture and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

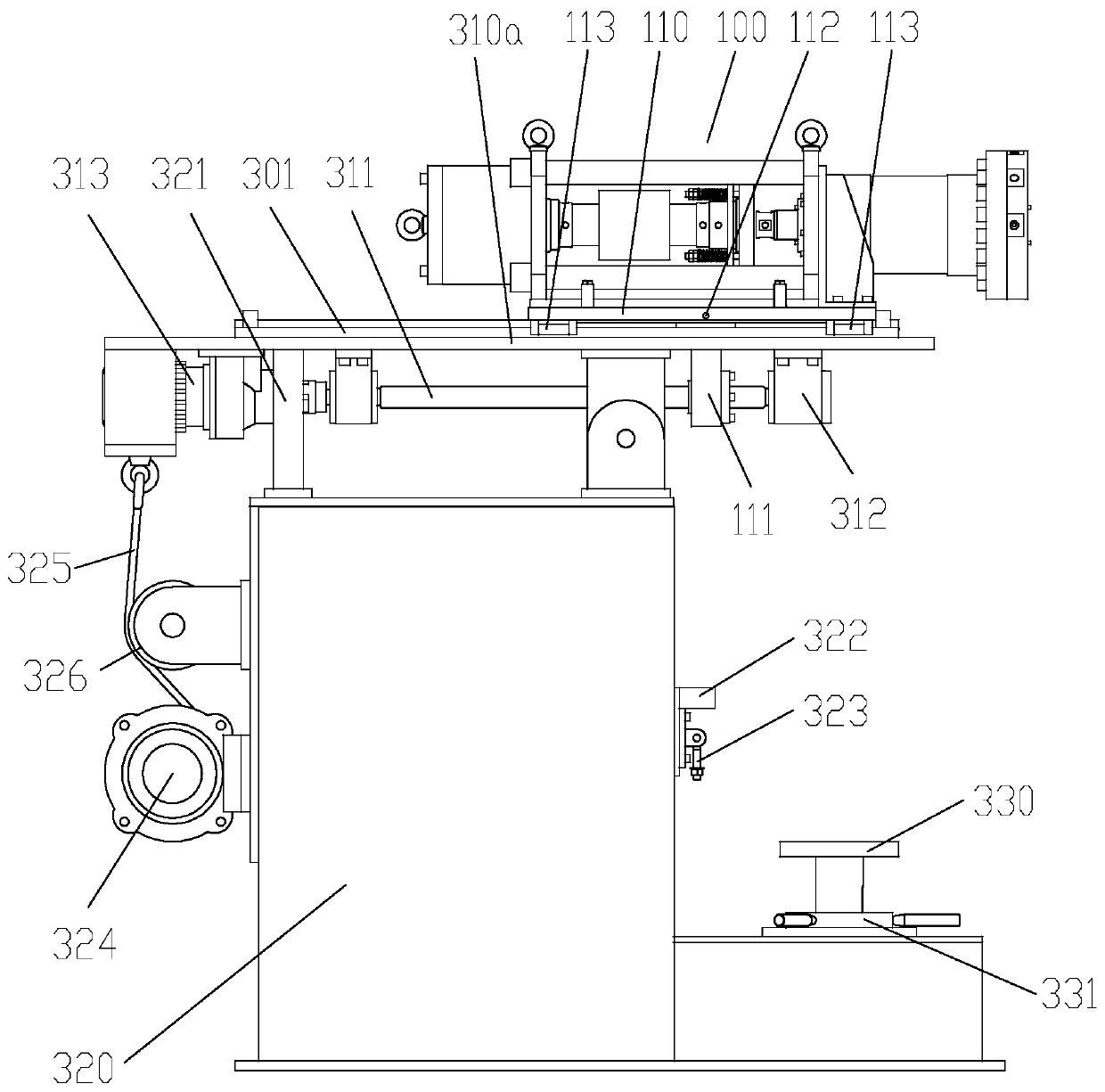

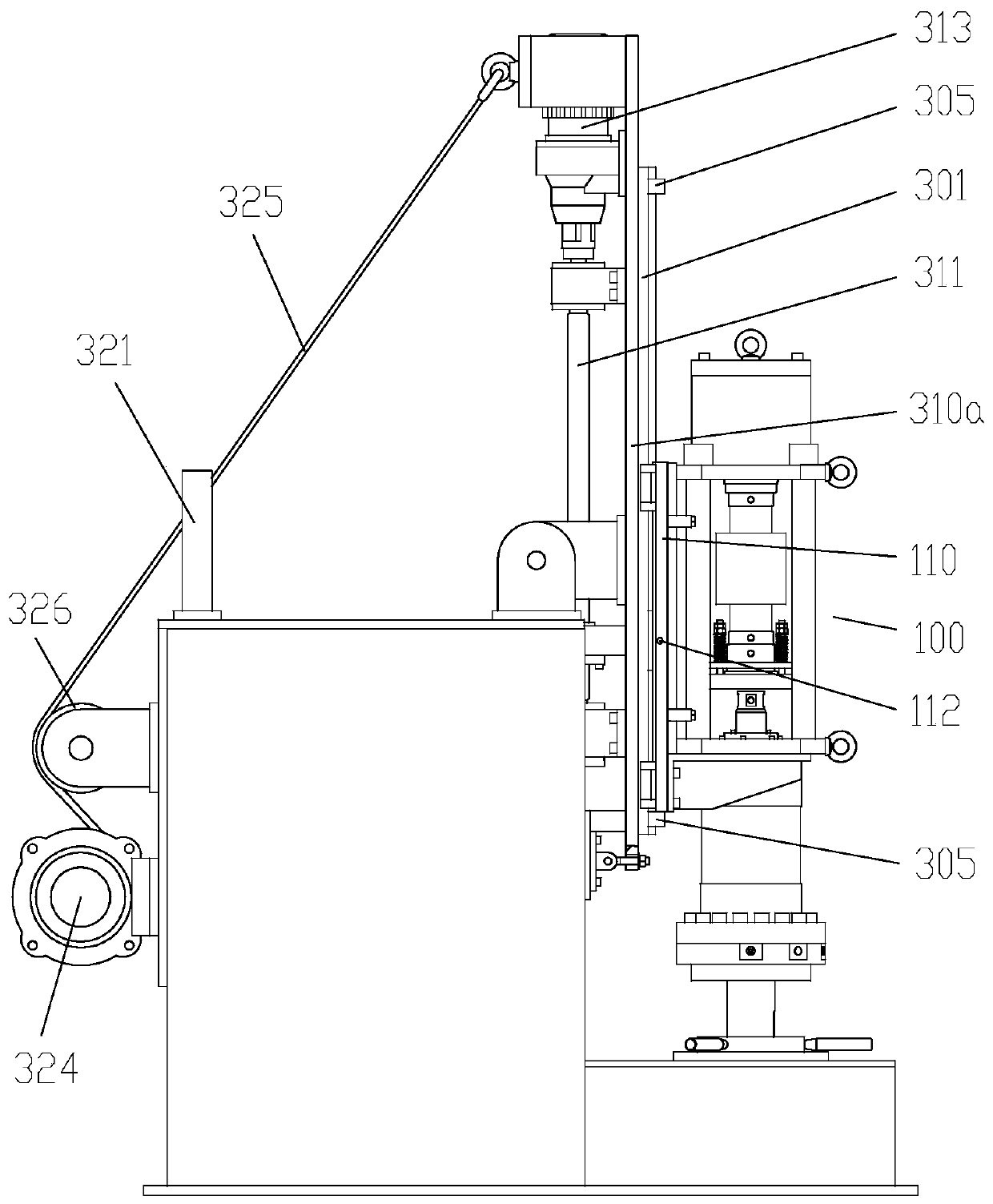

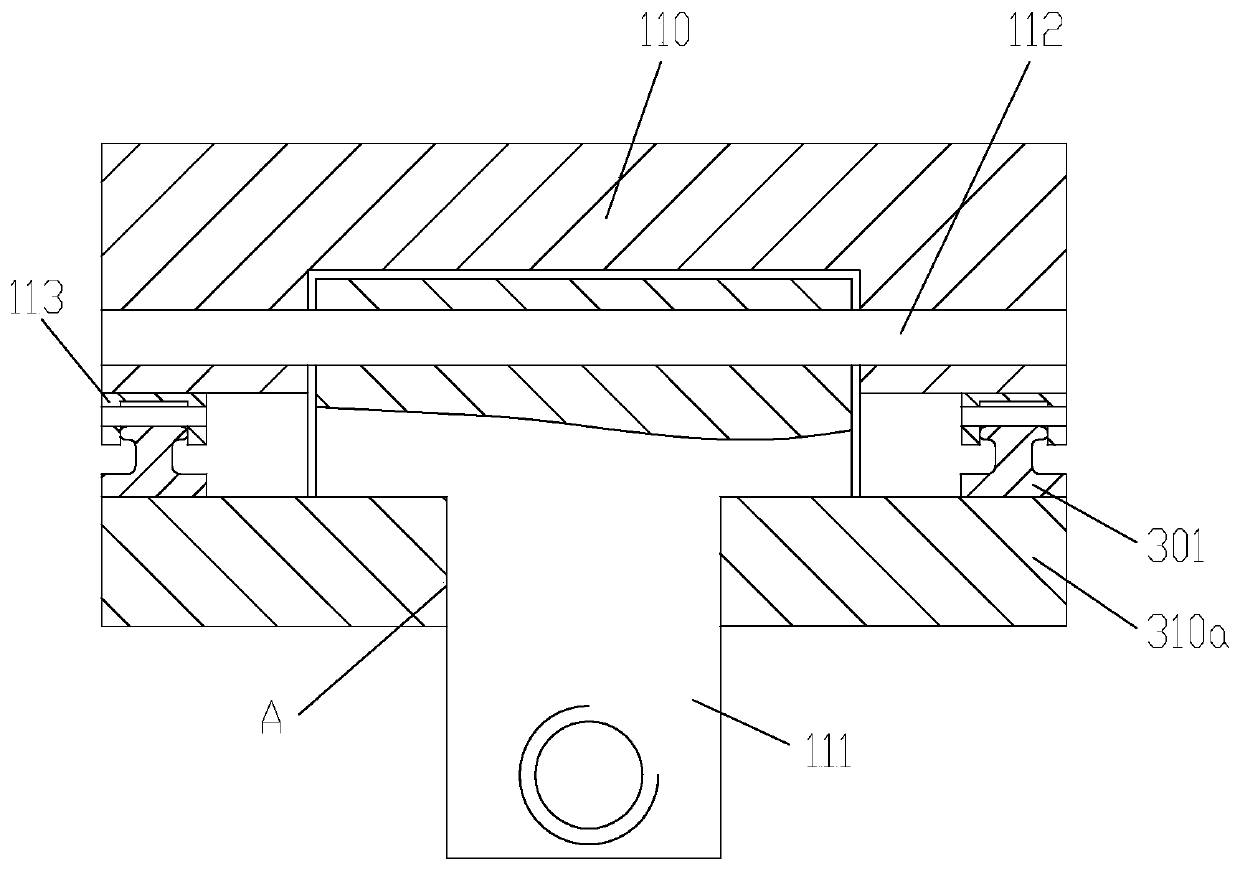

[0024] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , a thermal-fluid-solid coupling CT triaxial pressure chamber lifting device for loaded coal and rock mass, which constitutes a loading unit 300 for a triaxial test unit 100, the triaxial test unit 100 is provided with a triaxial pressure chamber, and the triaxial test unit 100 passes through the loading unit 300 To install the rock sample, the triaxial test unit 100 is set on the loading platform 310a of the loading unit 300, and a straight line for the triaxial test unit 100 is provided between the loading platform 310a and the triaxial test unit 100. A moving linear guide rail pair structure; a mobile drive device for driving the triaxial test unit 100 is provided between the loading plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com