Abrasion-resistant abrasive paper provided with porous structure

A porous structure, wear-resistant sand technology, applied in the field of grinding tools, can solve the problems of short service life, easy blockage of the grinding layer, poor wear resistance of the grinding layer, etc., so as to improve the service life, improve the grinding effect, prolong the The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

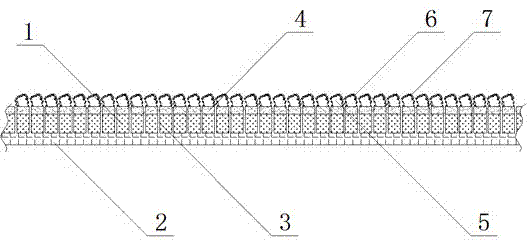

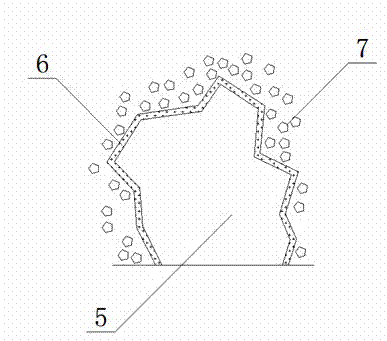

[0017] see figure 1 , figure 2 , a kind of wear-resistant sandpaper with porous structure that the present invention relates to, comprises paper substrate layer 1 and primer layer 4, and the upper surface of paper substrate layer 1 is provided with primer layer 4, and the bottom of described paper substrate layer 1 A layer of mesh cloth layer 2 is bonded to the surface, and the upper surface of the primer layer 4 is provided with a large particle wear-resistant layer 5. The coating layer 7 is pressed with micropores 3 penetrating through the paper base layer 1 and the primer layer 4 on the surface of the paper base layer 1 .

[0018] The large particle wear-resistant layer 5 is made by mixing large particles of titanium dioxide, large particles of silicon dioxide and large particles of calcium carbonate.

[0019] The adhesive 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com