Press-fitting tool for spark plug barrel of cylinder cover

A technology for press-fitting tools and cylinder heads, which is used in manufacturing tools, metal processing, hand-held tools, etc., can solve the problems of complicated operation procedures, affecting assembly efficiency, affecting the quality of the water cavity of the copper sleeve sealed cylinder head, etc., and achieves convenient operation. , High assembly efficiency, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

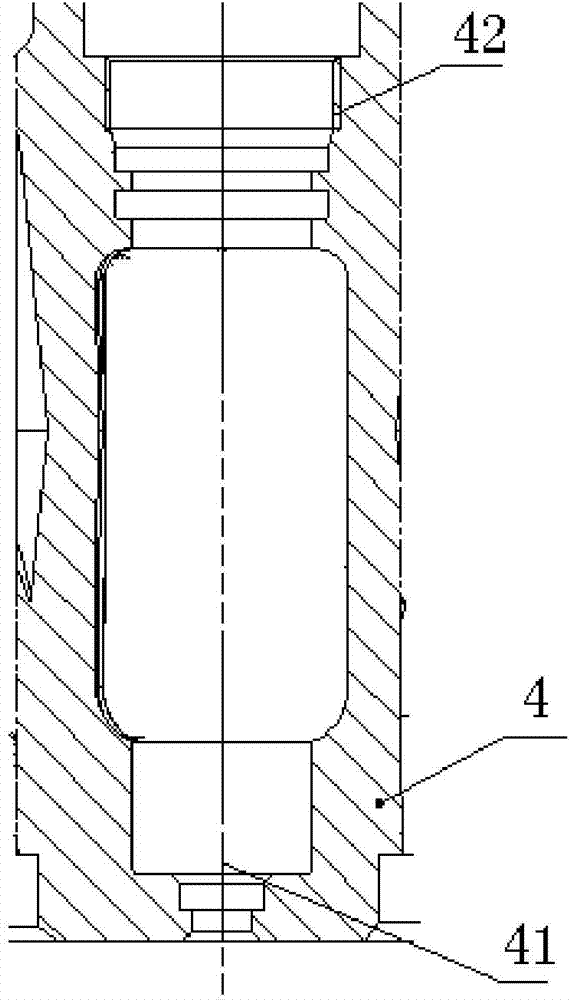

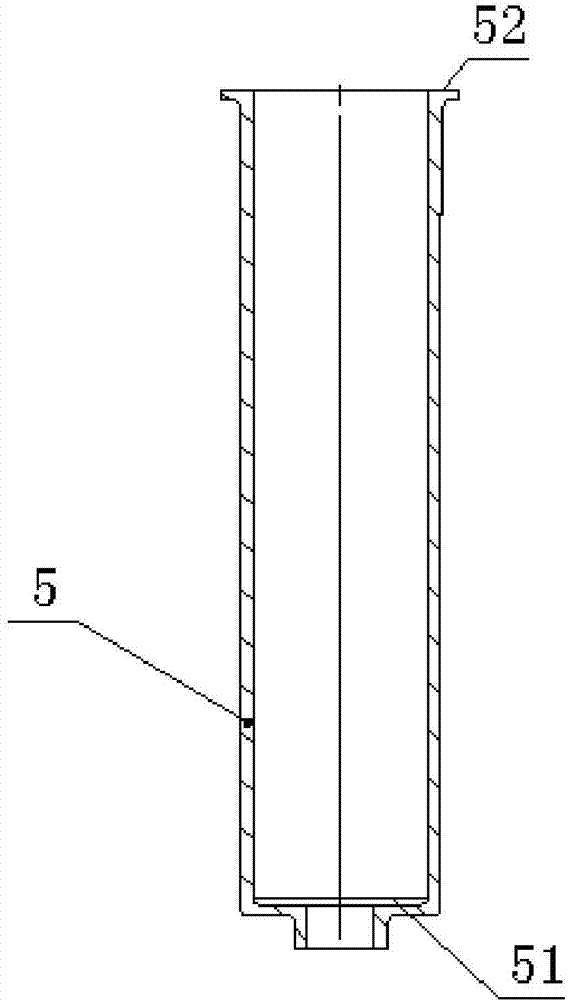

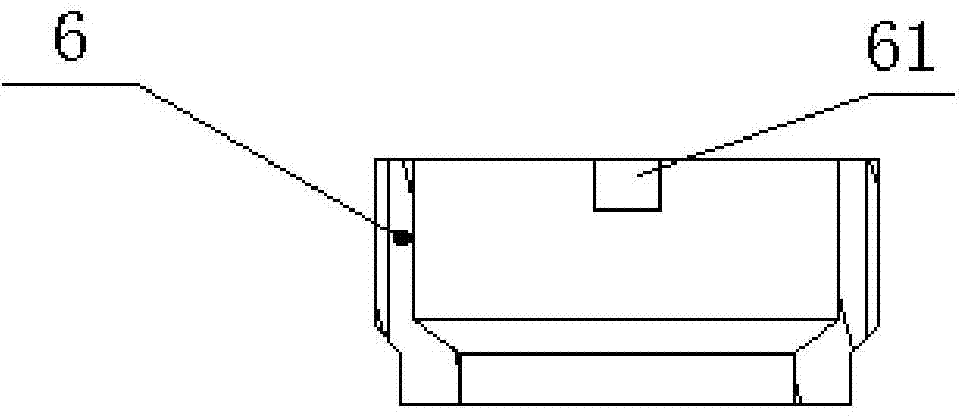

[0022] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment. It should be understood that the "upper", "lower", "left", "right", "front" and "reverse" mentioned in the following embodiments of the present invention are all based on the directions shown in the figures, These words used to limit the direction are only for convenience of description, and do not mean to limit the specific technical solution of the present invention.

[0023] The cylinder head spark plug screw sleeve pressing tool of the present invention has a simple and reasonable structure. Through the steps of composite pressing the end face of the copper sleeve and tightening the screw sleeve, the copper sleeve can be tightened without pressure release, which can ensure that the lower end surface of the copper sleeve i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com