Specialized maintenance device for spindle knife locking belleville spring

A technology of butterfly spring and locking knife, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of heavy workload, disc spring ejection, danger, etc., and achieve the effects of high precision, safe and reliable fixing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

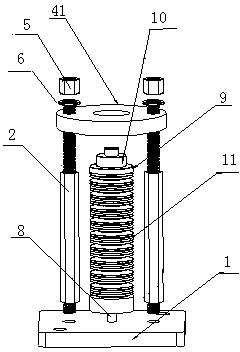

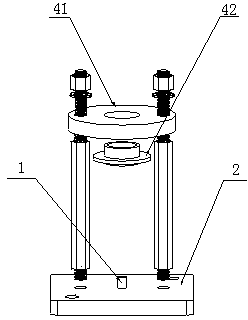

[0014] Such as figure 1 , 4 As shown, a professional device for overhauling the butterfly spring of the main shaft lock knife, including a base 1, an adjusting screw 2, and a shaft pressing plate 4, a pair of adjusting screws 2 are installed on the base 1, and a shaft pressing plate 4 is installed on the pair of adjusting screws 2 , the end of each adjusting screw 2 is provided with a nut 5 and a washer 6, and the center of the base 1 is provided with an anti-slip positioning pin 8. The shaft pressing plate 4 is a BT50 shaft pressing plate or a BT40 shaft pressing plate. A washer 6 is provided between the nut 5 and the shaft pressing plate 4 to further avoid friction between the nut and the shaft pressing plate. In the present invention, the bottom plate 1 is installed on the workbench 14 and fixed with fixing bolts 12, usually on two T-shaped slots 13.

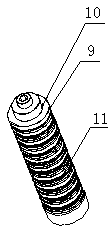

[0015] Embodiment one of the present invention, for BT50 spring assembly series, such as figure 1 , 3 As shown, use th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com