MCF equipment vacuum chamber-oriented remote conveying manipulator

A technology of manipulators and vacuum chambers, which is applied in the field of long-distance transport manipulators, can solve problems such as complex, narrow entrances restricting the scope of large-scale maneuvers, and high control complexity, so as to save use costs, reduce wiring complexity, and increase versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention are described in detail below: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

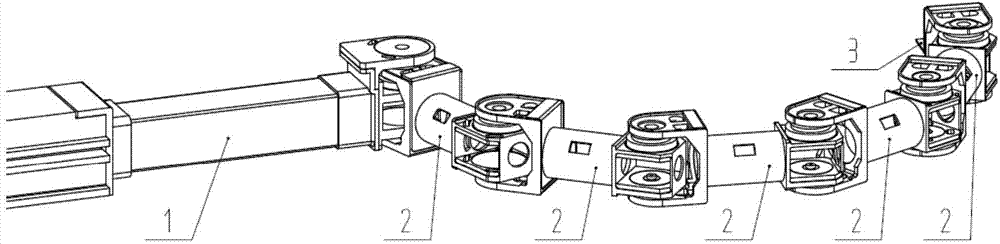

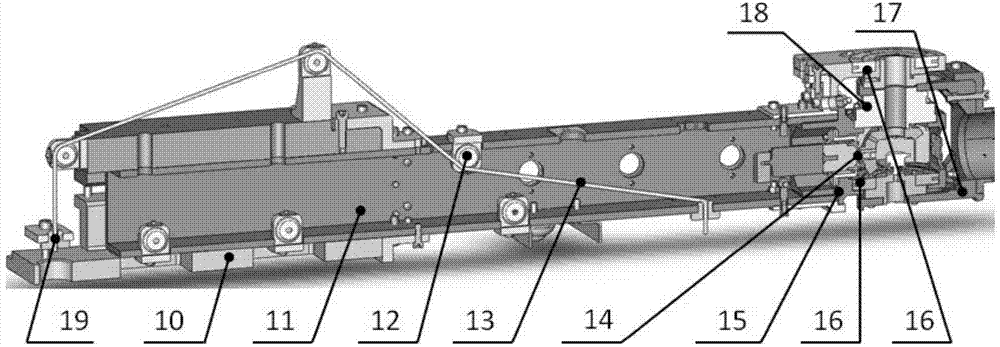

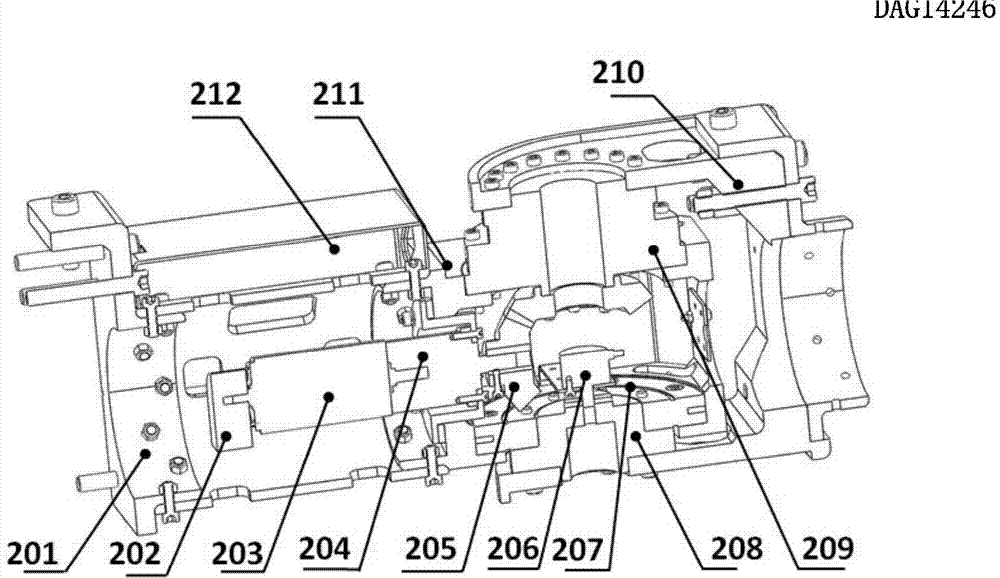

[0027] Such as figure 1 As shown, this embodiment provides a remote carrying manipulator oriented to MCF equipped with a vacuum chamber, including a torque compensation type manipulator joint 1, a plurality of space bearing component manipulator joints 2, a remote operation and maintenance manipulator support Seat 3. All the joints are connected through the EtherCAT bus, and the transmission mechanism of each space-bearing componentized manipulator joint is similar to the torque-compensated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com