Plastic cutting device

A cutting device and plastic technology, applied in the direction of metal processing, etc., can solve the problems that the plastic cutting device has a single structure and cannot adapt to various workplaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

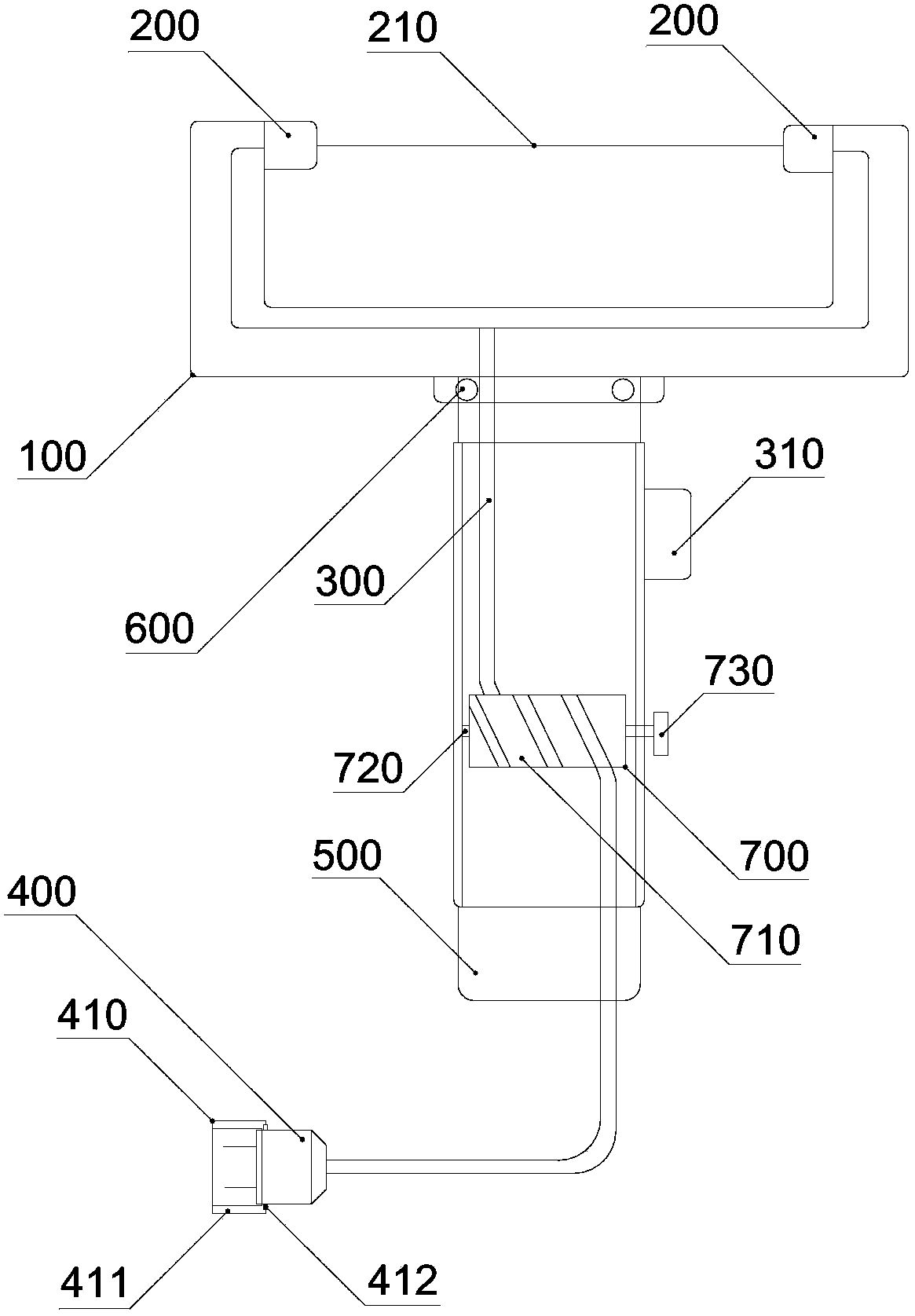

[0022] see figure 1 , a plastic cutting device, including a housing 100 with a handle 500, two corresponding metal probes 200 are installed on the housing 100, and a metal probe that generates heat through an electric current and cuts plastic is connected between the two metal probes 200 The wire 210 and the metal probe 200 are connected to the power plug 400 through the wire 300, and the wire 300 has a switch 310, and the handle 500 is hingedly connected with the housing 100 to achieve the purpose of adjusting different working states of the cutting device.

[0023] A plastic cutting device, which also includes a limit hole 600 and a limit post (not shown in the figure) arranged at the hinge joint between the housing 100 and the handle 500. The limit post is installed in the limit hole 600 for adjusting the hinge Fix the handle 500 and the housing 100 after the angle of connection is fixed. When the cutting device is expanded horizontally, a limit post is inserted into the ve...

Embodiment 2

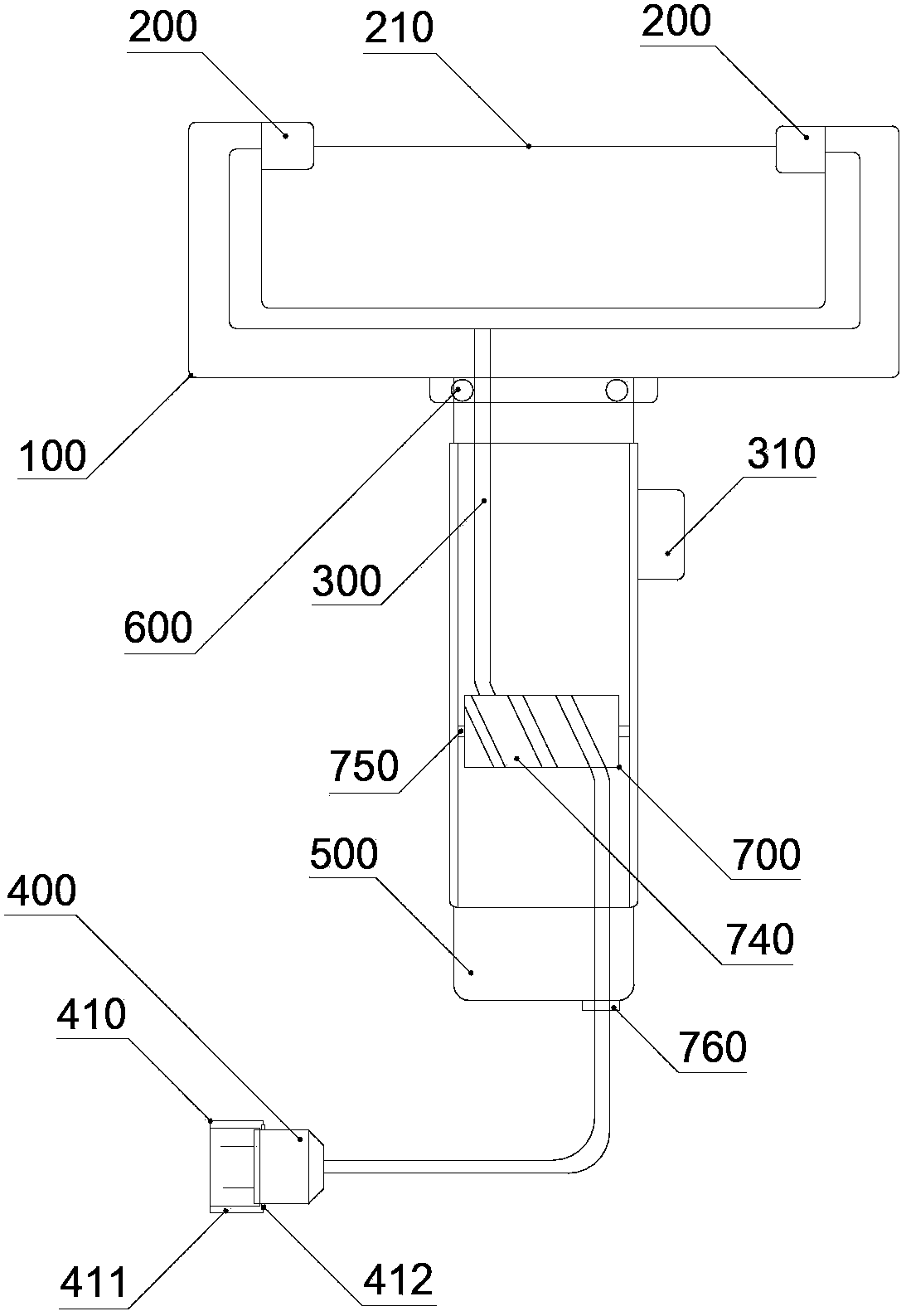

[0033] see figure 2 , a plastic cutting device, including a housing 100 with a handle 500 for hand holding, two corresponding metal probes 200 are installed on the housing 100, and the two metal probes 200 are connected to generate heat through an electric current and The metal wire 210 for cutting plastic, the metal probe 200 is connected to the power plug 400 through the wire 300, and the wire 300 has a switch 310, and the handle 500 is hinged with the housing 100 to achieve the purpose of adjusting different working states of the cutting device.

[0034] A plastic cutting device, which also includes a limit hole 600 and a limit post (not shown in the figure) arranged at the hinge joint between the housing 100 and the handle 500. The limit post is installed in the limit hole 600 for adjusting the hinge Fix the handle 500 and the housing 100 after the angle of connection is fixed. When the cutting device is expanded horizontally, a limit post is inserted into the vertical li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com