Shrinking device with optimised energy management

A technology of equipment and shrinking medium, which is applied in the direction of wrapping paper shrinkage, packaging, wrapping paper, etc., and can solve the problem of low heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

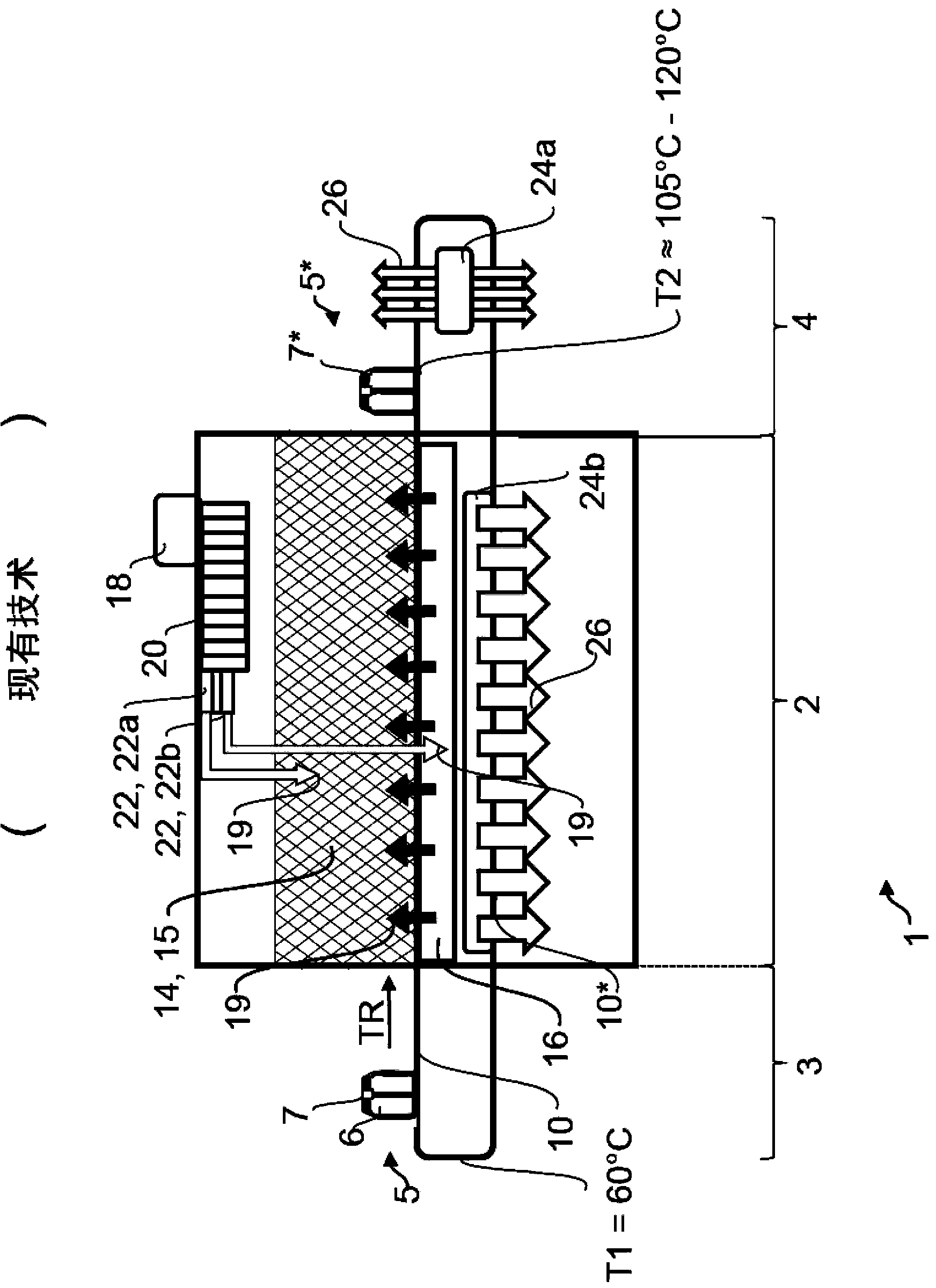

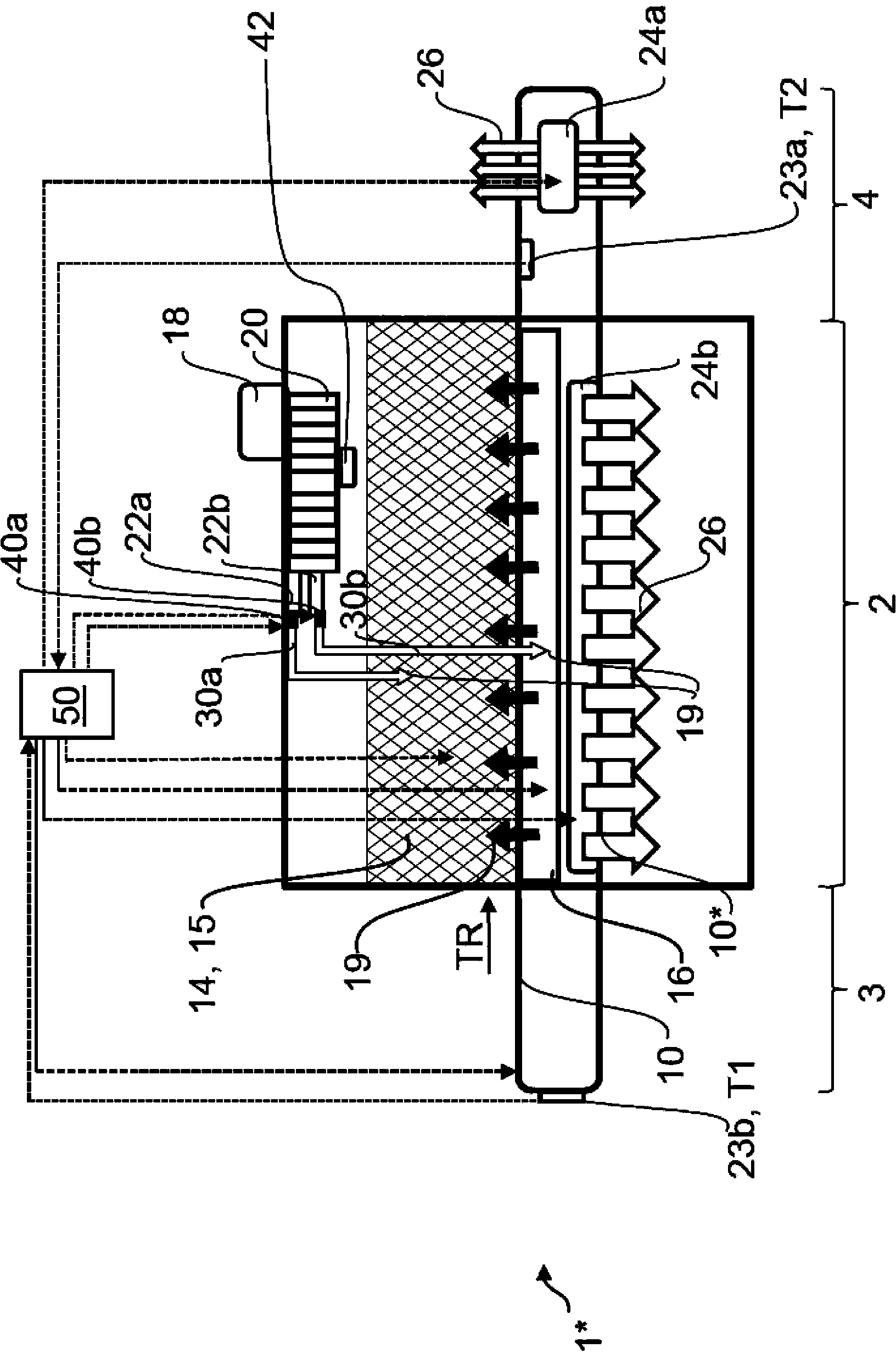

[0051] The same reference numerals are used for the same or the same elements of the present invention. In addition, for the sake of clarity, only the reference numerals necessary for describing each drawing are shown in each drawing. The illustrated embodiment is only an example to describe how the device according to the invention or the method according to the invention can be constructed, but it is not a closed limitation.

[0052] figure 2 In the schematic diagram, a contraction device 1* with energy management according to the invention is shown. The shrinking device 1* is mostly the same as the shrinking device 1 known from the prior art (refer to figure 1 ) Is similar, so you can refer to its description. The throttle valves 22a and 22b are respectively equipped with adjusting drivers 40a and 40b, and the throttle valves 22a and 22b can be opened or closed by means of the adjusting drivers. The adjusting drives 40a, 40b are connected to the control unit 50, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com