A kind of short fiber rotor composite yarn spinning method

A composite yarn and short fiber technology, which is applied in the field of rotor spinning machine and short fiber rotor composite yarn spinning, can solve the problems affecting the appearance and strength of the rotor spinning yarn, and the fiber strength cannot be fully utilized, and achieves an increase in the Aesthetics, reduced straddle fiber formation, improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the drawings and embodiments.

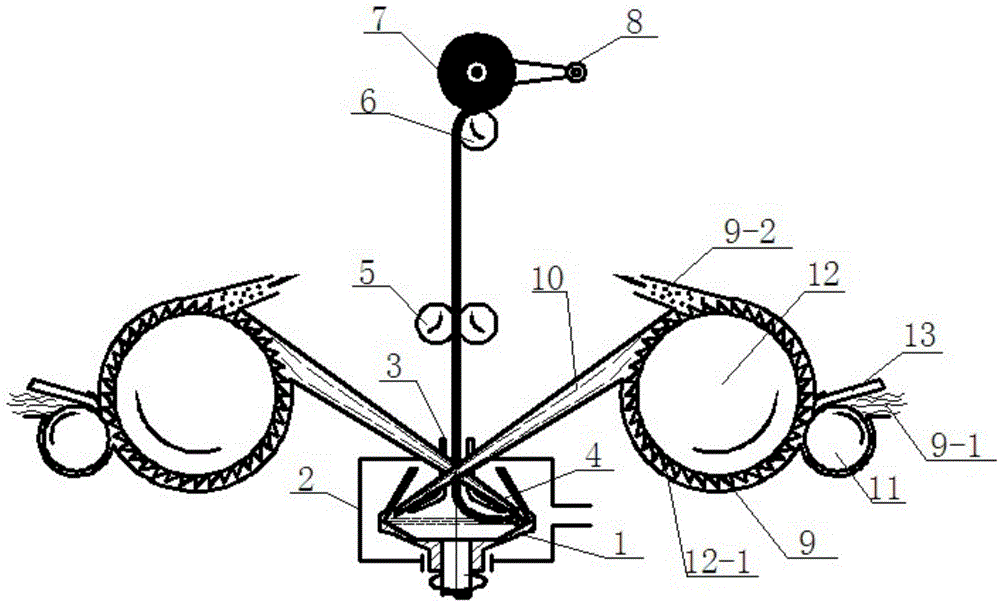

[0029] Such as figure 1 As shown, a device used in the spinning method of short fiber rotor composite yarn includes a condensing and twisting mechanism, a winding forming mechanism and a feeding and opening mechanism; two feeding and opening mechanisms are symmetrically arranged on both sides of the condensing and twisting mechanism .

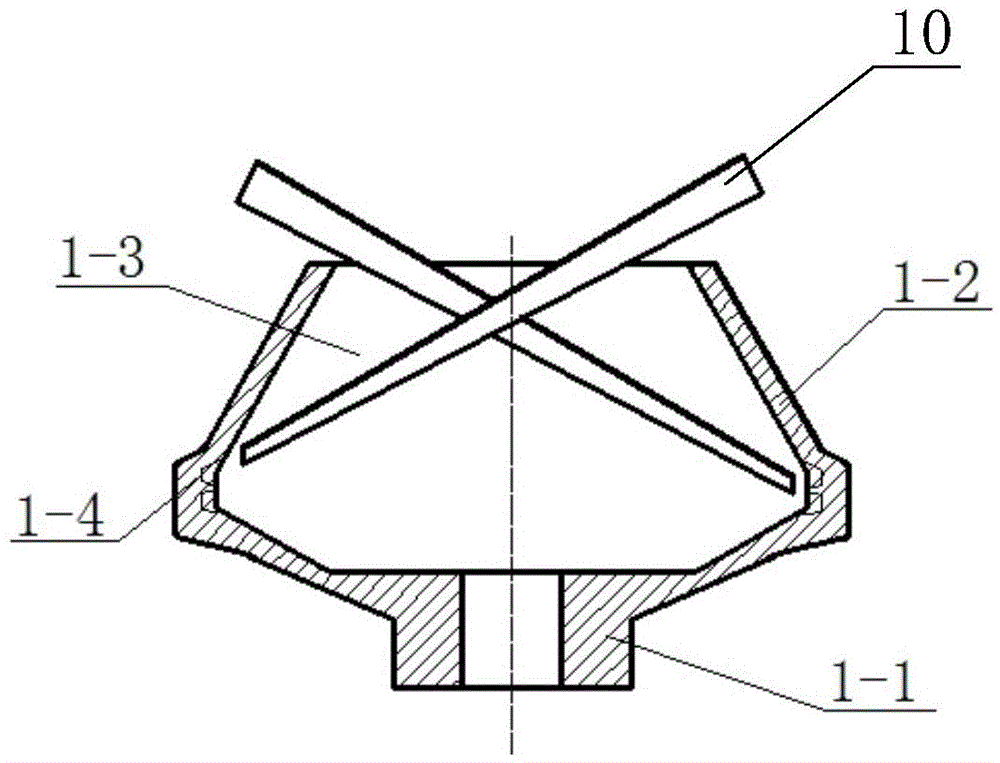

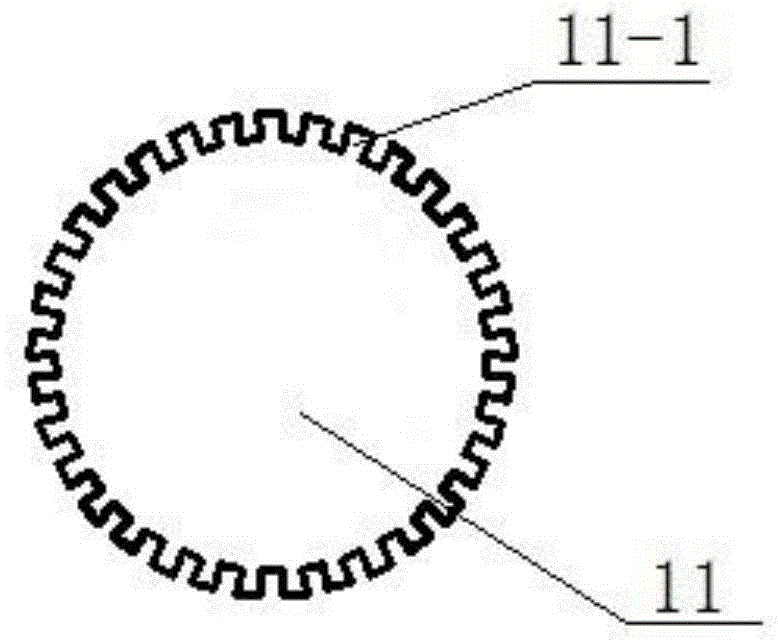

[0030] Such as figure 1 with 2 As shown, the condensing and twisting mechanism includes a spinning cup 1, an air extraction device 2, a yarn take-up tube 3, and a twist blocking disk 4. The spinning cup 1 includes an integrally formed and coaxially arranged cup holder 1-1 and a cup body 1-2, the cup holder 1-1 is arranged at the bottom of the cup body 1-2; the upper part of the cup body 1-2 is upright Round truncated cone shape, the lower part is inverted truncated truncated cone shape, the inside is opened along the axis with cavities 1-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com