A kind of beneficiation method for separating rare metal concentrate and quartz feldspar concentrate

A technology of rare metals and mineral processing methods, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of difficult development, low recovery rate, complex mineral composition, etc., achieve low cost of mineral processing and increase recovery rate , The effect of improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

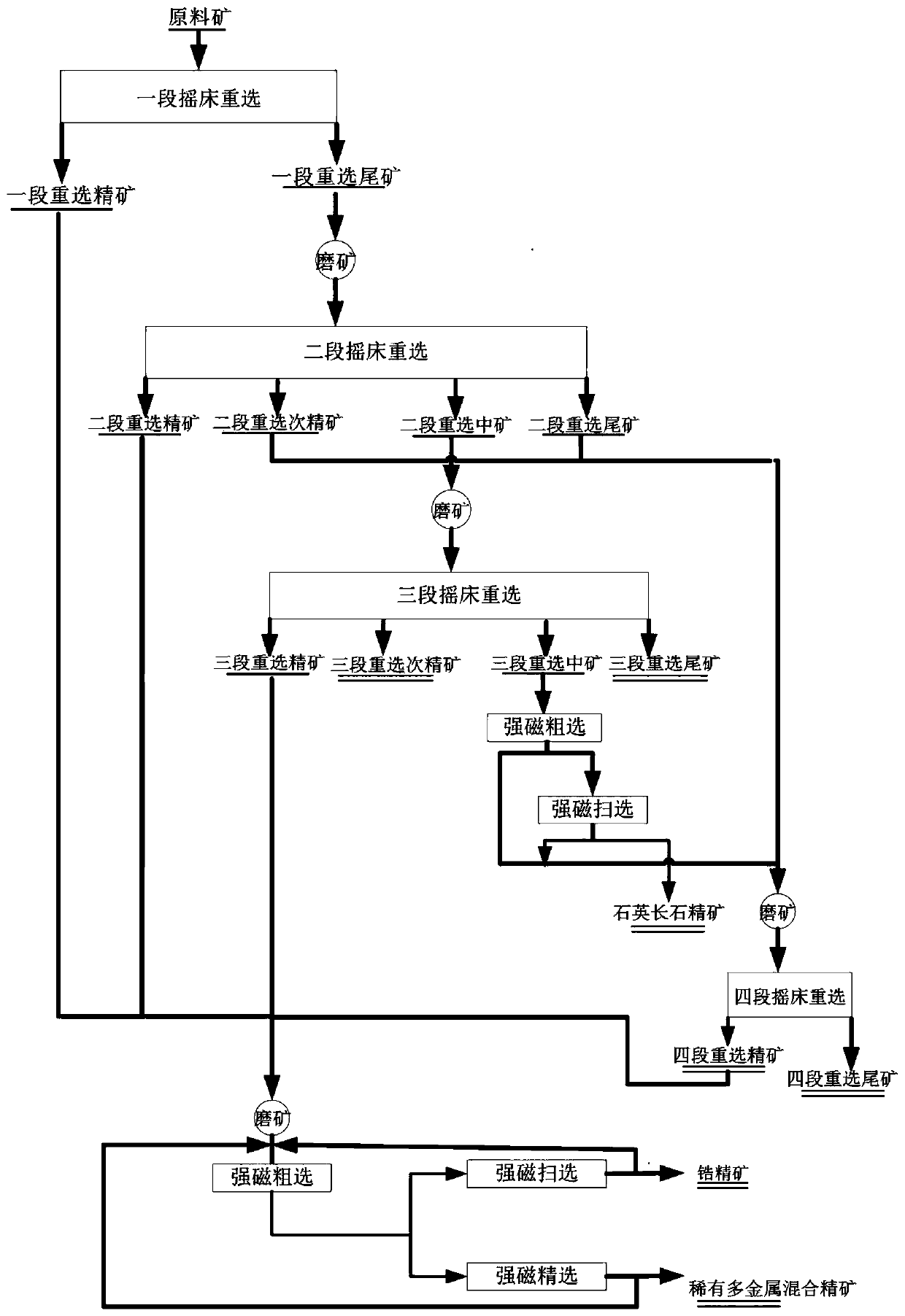

[0037] With the rare metal zirconium, uranium, niobium, beryllium, rare earth, titanium mineral total amount as 5.0%, the polymetallic ore with quartz feldspar content of 85.0% as raw material ore, using the process method of the present invention, such as figure 1 As shown, the following process steps are carried out:

[0038] (1) Take the polymetallic ore whose particle size is -0.5mm and account for more than 50%, carry out one stage of shaker gravity separation, obtain one stage of gravity separation concentrate and one stage of gravity separation tailings; the condition of the first stage of shaker gravity separation is 30% , the mass ratio of the first section of gravity separation concentrate and one section of gravity separation tailings is 2:98;

[0039] (2) Grinding the one-stage gravity-selection tailings described in step (1) until the particle size is -0.1mm, the weight percentage accounts for more than 80%, and carrying out two-stage shaker gravity separation to ...

Embodiment 2

[0045] With the rare metal zirconium, uranium, niobium, beryllium, rare earth, titanium mineral total amount as 8.65%, the polymetallic ore with quartz feldspar content 78.30% as raw material ore, utilize the process method of the present invention to carry out the following process steps:

[0046] (1) Take the polymetallic ore whose particle size is -0.5mm and account for more than 85%, and carry out one stage of shaking table gravity separation to obtain one stage of gravity separation concentrate and one stage of gravity separation tailings; the condition of said one stage of shaking table gravity separation is ore pulp concentration 10%, the mass ratio of the first stage of gravity separation concentrate and the first stage of gravity separation tailings is 1.8:98.2;

[0047] (2) Grinding the one-stage gravity-selection tailings described in step (1) until the particle size is -0.1mm, the weight percentage accounts for more than 85%, and carrying out two-stage shaker gravit...

Embodiment 3

[0053] With the rare metal zirconium, uranium, niobium, beryllium, rare earth, titanium mineral total amount as 10.25%, the polymetallic ore with quartz feldspar content 82.67% as raw material ore, utilize the process method of the present invention to carry out the following process steps:

[0054] (1) Take the polymetallic ore whose particle size is -0.5mm and account for more than 70%, carry out one stage of shaking table gravity separation, obtain one stage of gravity separation concentrate and one stage of gravity separation tailings; the condition of said one stage of shaking table gravity separation is the concentration of ore pulp 30%, the mass ratio of the first stage of gravity separation concentrate and the first stage of gravity separation tailings is 5:95;

[0055] (2) Grinding the one-stage gravity-selection tailings described in step (1) until the particle size is -0.1mm, the weight percentage accounts for more than 80%, and carrying out two-stage shaker gravity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com