Tube

A marking and fluid flow technology, applied in the direction of hoses, pipes, piping systems, etc., can solve problems such as delay in connecting pipes, pipe identification, and inability to fall off marks, so as to reduce costs, save labor and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

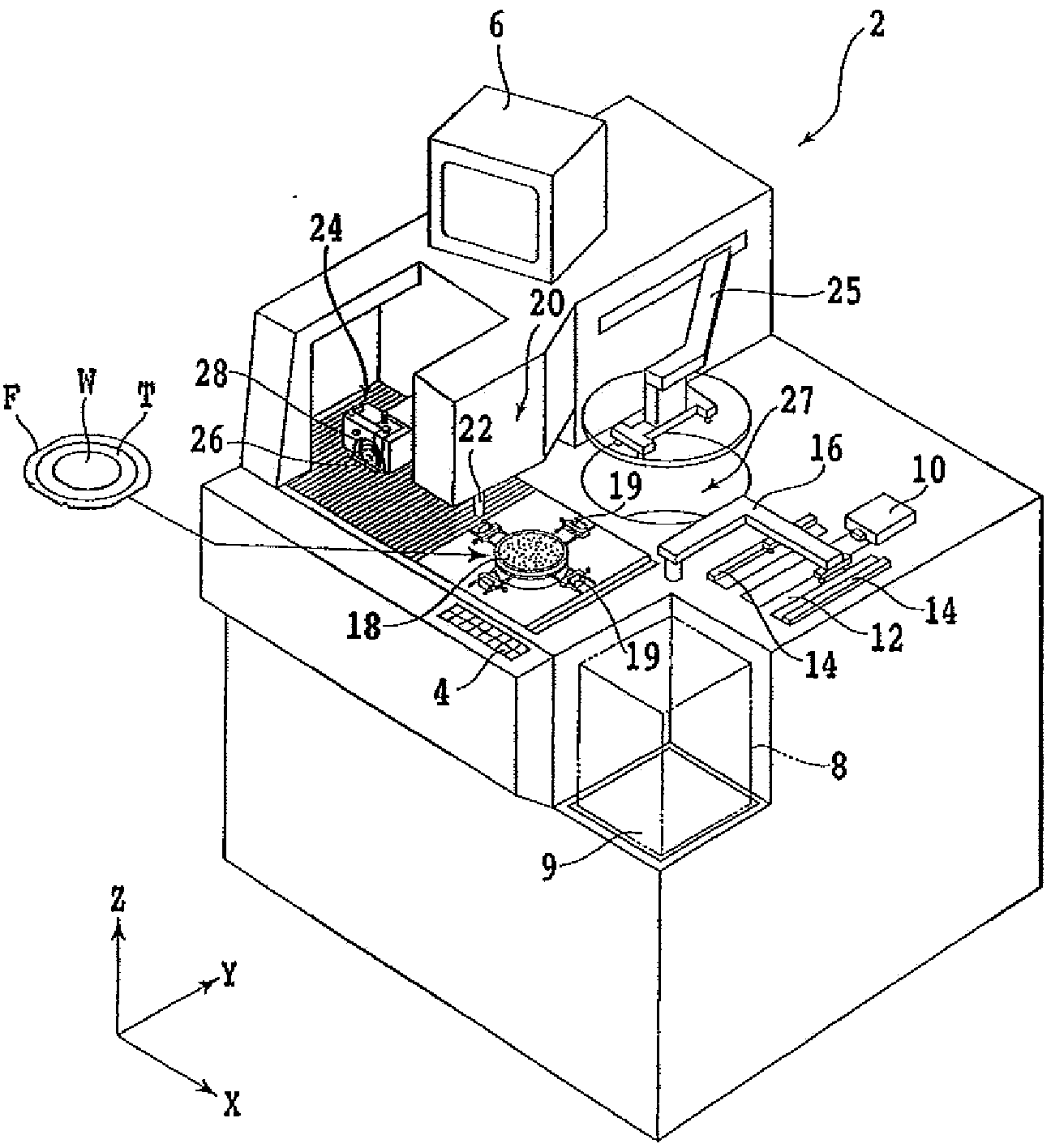

[0034] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is an external perspective view showing a cutting device 2 using the pipe of the present invention for piping. On the front side of the cutting device 2 is provided an operating member 4 for an operator to input instructions to the device such as machining conditions. A display unit 6 such as a CRT is installed on the upper part of the device, and the display unit 6 displays a guidance screen for an operator and an image captured by an imaging unit described later.

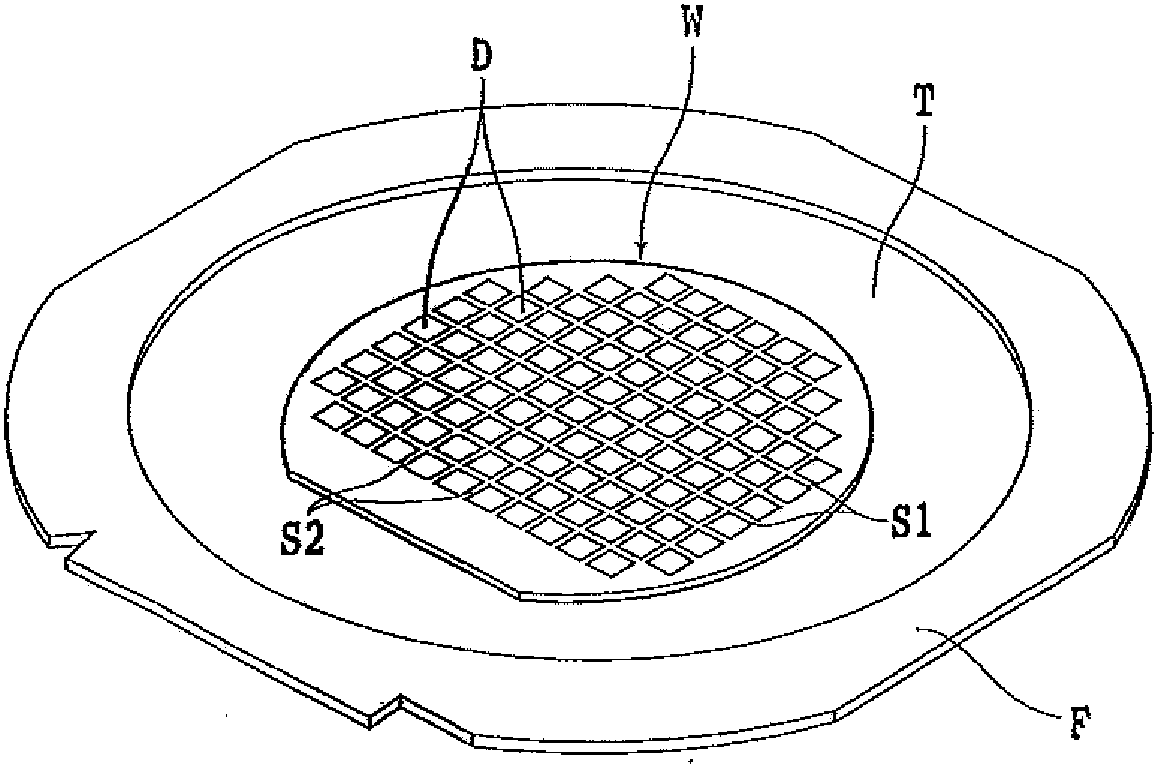

[0035] like figure 2 As shown, on the surface of a light-emitting device wafer W (hereinafter, simply referred to as "wafer W") as a dicing object, first street (segmentation plan line) S1 and second street S2 are formed orthogonally. A plurality of devices D such as LEDs divided by the first spacer S1 and the second spacer S2 are formed thereon.

[0036] The wafer W is attached to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com