Feeding and propelling device for pipe internal leakage flux detector

A technology of propulsion device and detector, applied in the direction of special pipe, pipe element, pipe/pipe joint/pipe fitting, etc., to achieve the effect of easy operation, improved efficiency and reduced work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

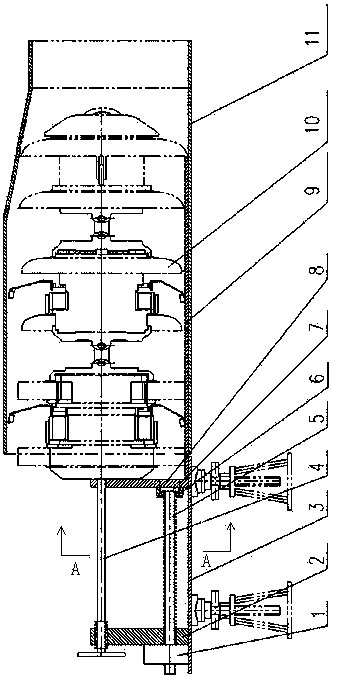

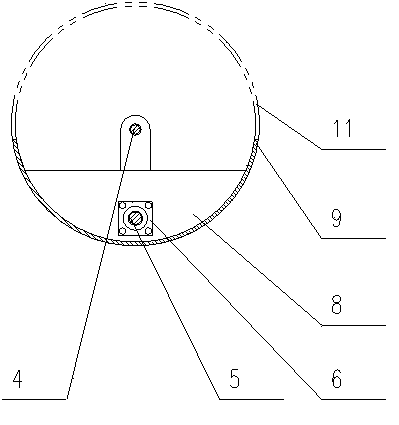

[0010] Now combined with the manual figure 1 , attached figure 2 The present invention is further described.

[0011] The feeding propulsion device is composed of a lead screw driving device 1, a solid block 2, a bracket 3, a push rod 4, a lead screw 5, a cover plate 6, an end plate 7, a baffle plate 8, a half-section pipe 9, and a variable-section feeder 11. It is used in conjunction with the magnetic flux leakage detector 10 . Bracket 3 and half-cut tube 9 have arc-shaped cross-sectional shapes. The radius of half-cut tube 9 is smaller than that of bracket 3. Half-cut tube 9 can be placed on bracket 3 and can slide. It is a circular structure with a radius not smaller than the radius of the bracket. The small end is a circular structure with the same radius as the pipeline to be detected. The large end and the small end are connected by a variable-section tube, and the bottom is horizontal. The bracket 3 is horizontally aligned with the variable-section dispenser 11, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com