Efficient heat exchange tube fin for filler coupling coil evaporative condenser

A technology of evaporative condenser and heat exchange fins, which is applied in evaporator/condenser, direct contact heat exchanger, water shower cooler, etc., can solve the problems of reduced heat exchange efficiency, achieve reduced usage, The effect of increasing the evaporation heat transfer surface area and improving the heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

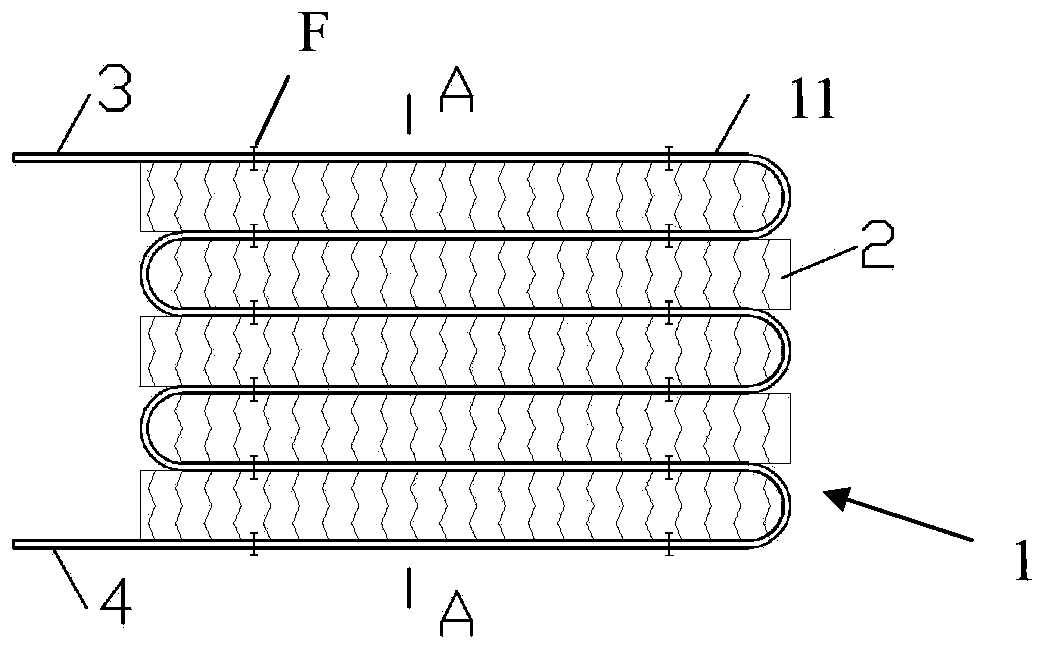

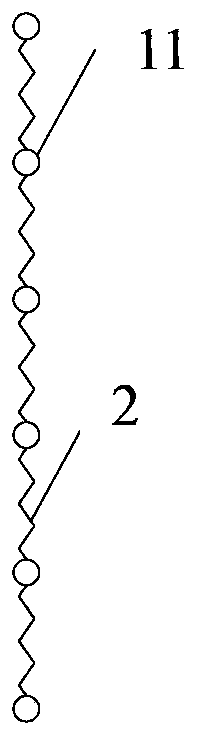

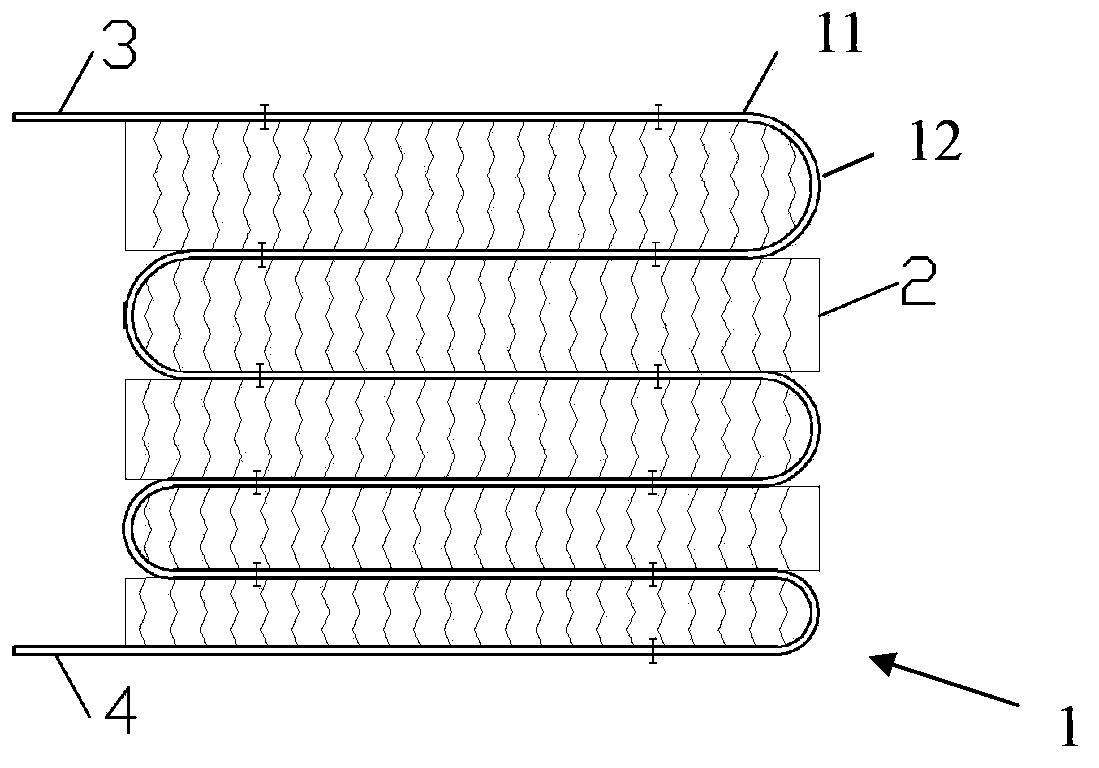

[0037] Image 6 shows another preferred heat exchange fin of the present invention, including coil 1 and packing 2 . The difference from the first embodiment above is that in the heat exchange tube sheet, the length of the straight pipe section of the heat exchange tube 11 gradually increases from the upper layer to the lower layer. To flow down to the heat exchange tube 11 located in the lower floor. The heat exchange fins provided in this embodiment are more suitable for an evaporative condenser using two sets of heat exchangers. Compared with Embodiment 1, in this embodiment, a fan with a larger size and horsepower can be installed by changing the length of the straight pipe section of the heat exchange tube 11 without changing the overall size of the condenser. see again Image 6 , the fans in the solid line are the heat exchange fins provided by this embodiment, and the fans in the dotted lines are the heat exchange fins with heat exchange tubes of equal length and str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com