Filler coupling coil evaporative condenser

An evaporative condenser and coil technology, applied in evaporator/condenser, water shower cooler, direct contact heat exchanger, etc., can solve the problem of unreasonable utilization of heat exchange area, no mechanical cleaning operation space, increase The use of metal materials and other issues can reduce the risk of scaling, reduce backward drift or flying water, and reduce the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

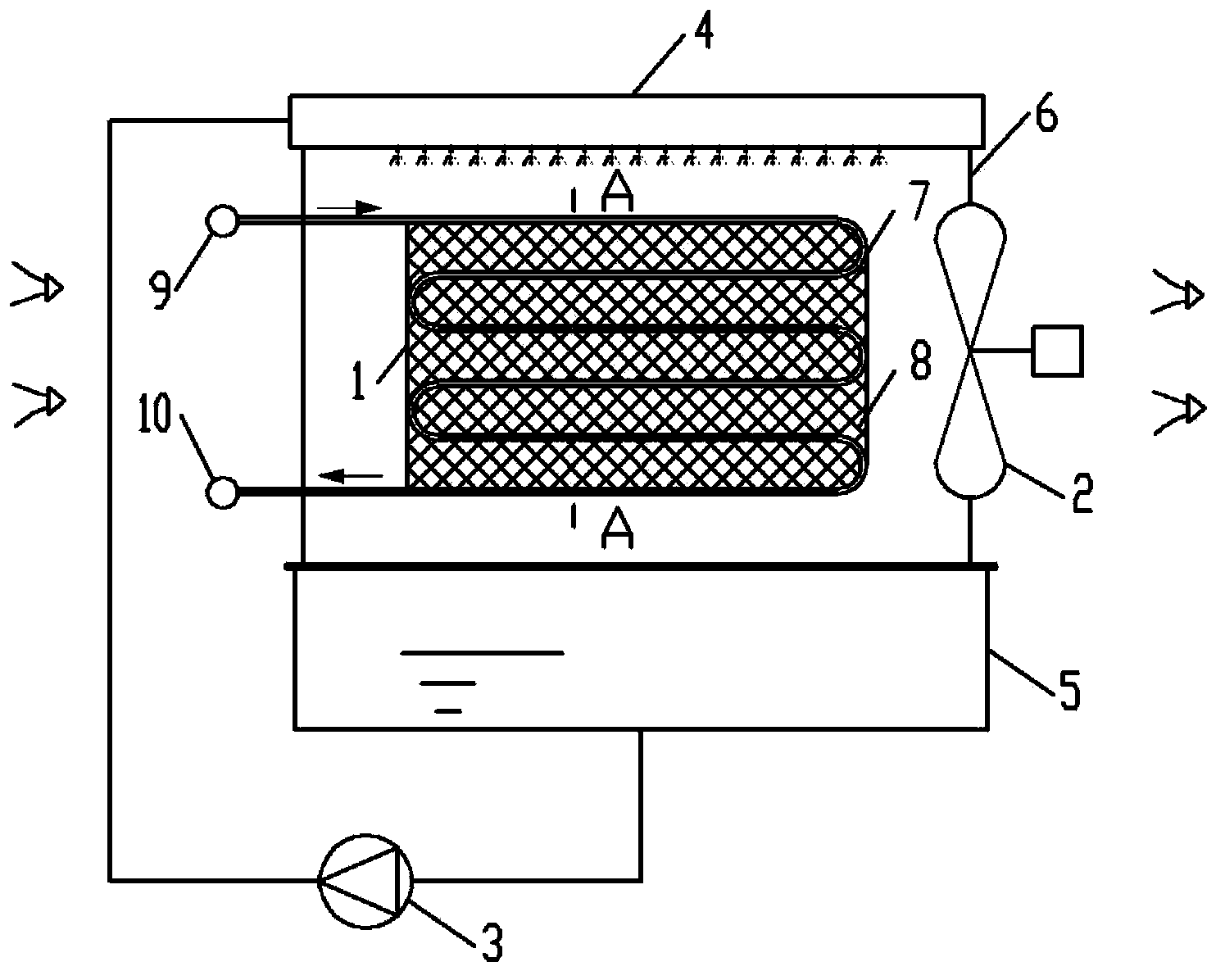

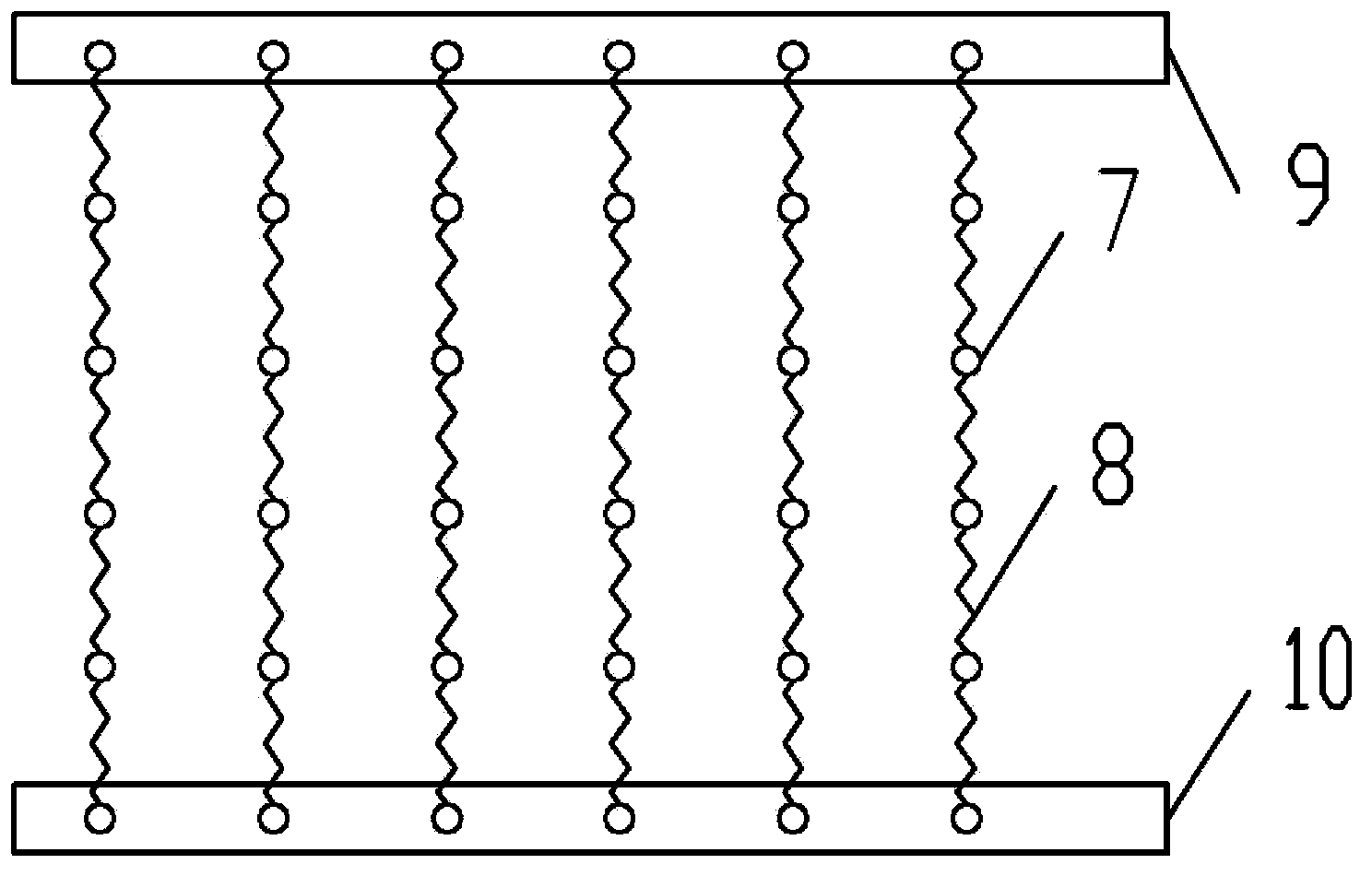

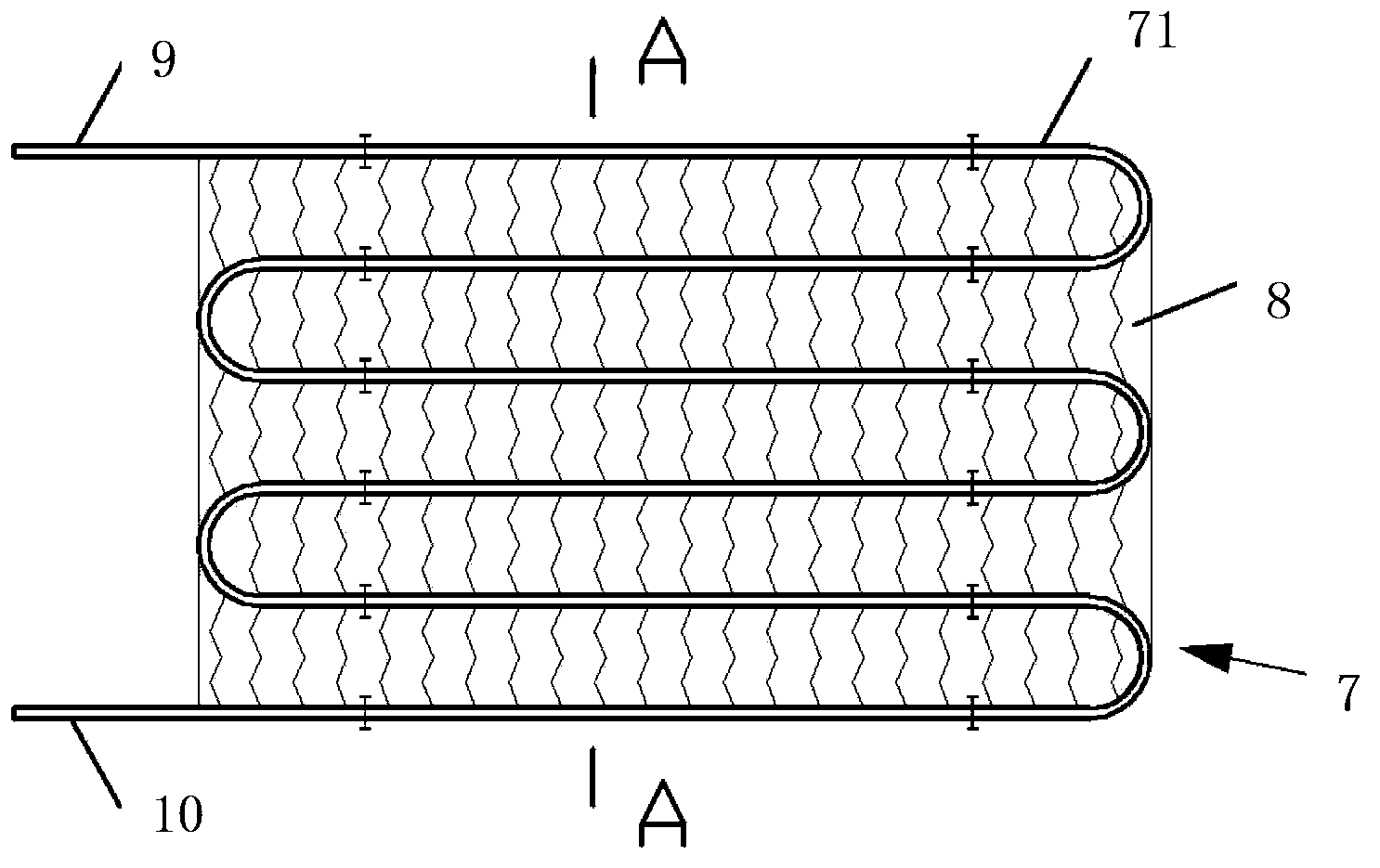

[0042] figure 1 , figure 2 The structure of the evaporative condenser of the present invention is shown, and the evaporative condenser includes a coil heat exchanger 1, a fan 2, a water pump 3, a water distributor 4, a sump 5 and a frame 6; the heat exchanger 1 consists of The heat exchange tube fins formed by a plurality of serpentine coils are connected by an inlet header 9 and an outlet header 10 . Each heat exchange fin includes a longitudinal serpentine (S-shaped) coil 7 and packing 8. The packing is arranged between the plane spaces formed by the serpentine coil. The packing and the coil form a tightly fitting structure, that is, the two are coupled. connected to form a segment structure. The coil is arranged vertically, that is, the cooling air blown by the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com