A water chiller with packing coupling coil evaporative condenser

A technology for evaporative condensers and water chillers, which is applied in the direction of evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of no mechanical cleaning operation space, difficult cleaning, and increased coil length, etc. The effect of reducing the risk of fouling, improving heat exchange efficiency, and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

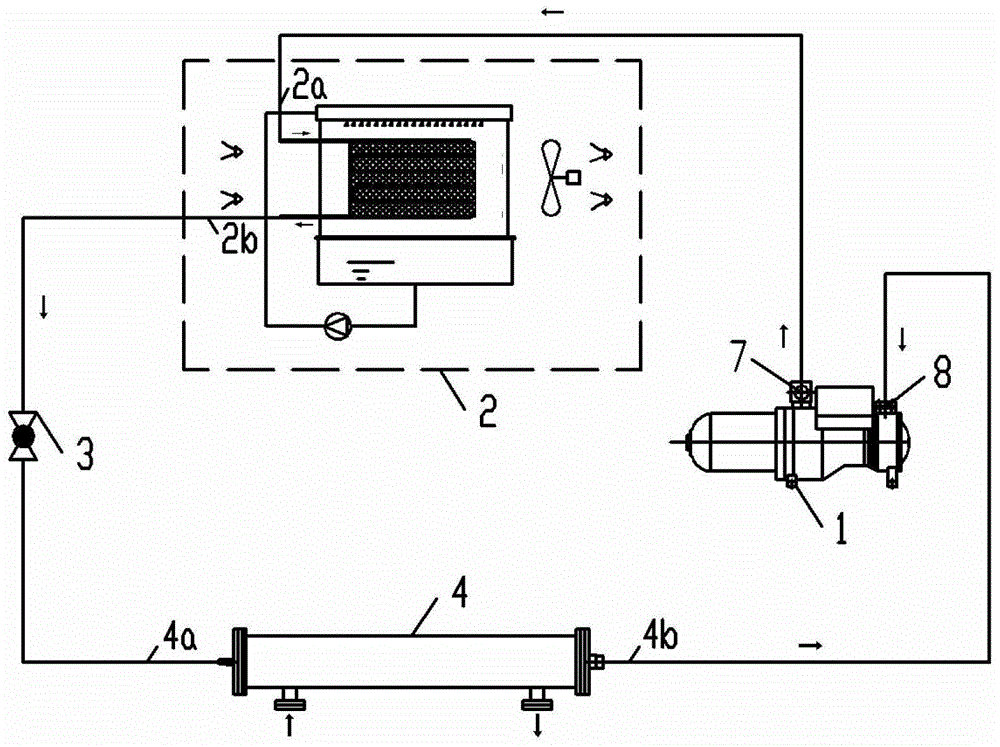

[0044] figure 1 A schematic diagram showing the principle of the refrigerating cycle mode of the water chiller of the present invention, by figure 1 It can be seen that the water chiller includes a compressor 1, an evaporative condenser 2, a throttling device 3 and an evaporator 4; the exhaust port 7 of the compressor is connected with the gas pipe 2a of the evaporative condenser, and the evaporative condenser The liquid pipe 2b is connected to the liquid pipe 4a of the evaporator through a throttling device, and the gas pipe 4b of the evaporator is connected to the suction port 8 of the compressor. The evaporative condenser 2 adopts longitudinally arranged coils coupled with fillers, which will not be described in detail here.

[0045]The working principle of the present invention: when the refrigerant is compressed by the compressor 1 and becomes a high-temperature and high-pressure gas, it enters the evaporative condenser 2 through the refrigeration system pipeline, and af...

Embodiment 2

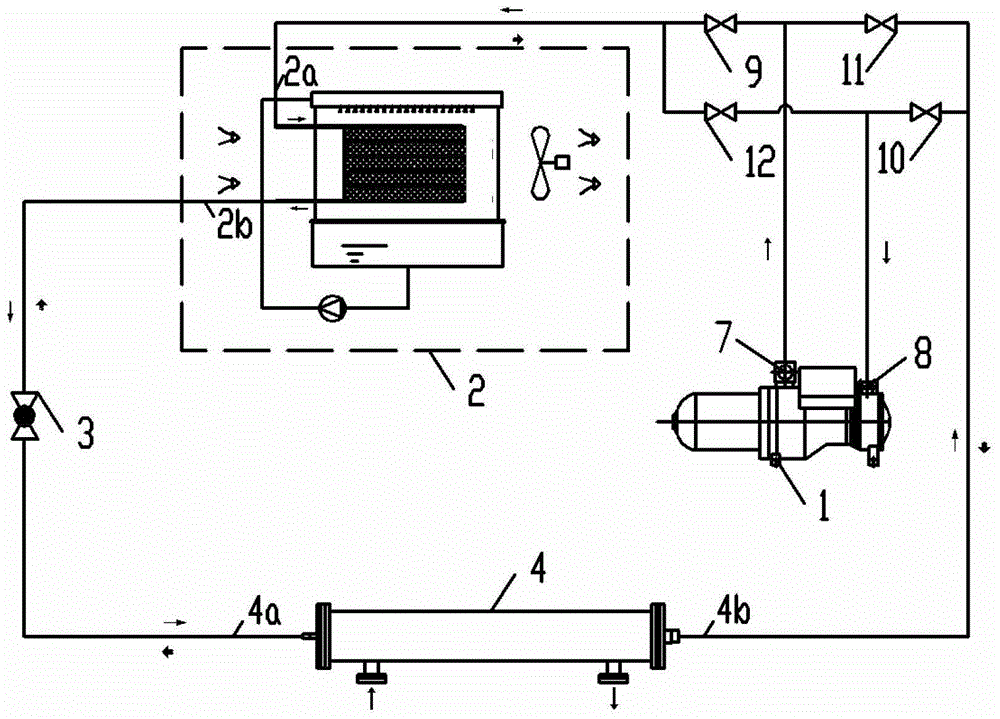

[0047] figure 2 It shows a schematic diagram of the principle of the water chiller of the present invention. Compared with Embodiment 1, the difference is that the water chiller is provided with a first refrigeration valve 9, a second refrigeration valve 10, a first heat pump valve 11 and a second refrigeration valve. Two heat pump valves 12; the first refrigeration valve 9 is arranged on the connecting pipeline between the exhaust port 7 of the compressor and the gas pipe 2a of the evaporative condenser, and the second refrigeration valve 10 is arranged on the air inlet 8 of the compressor and the evaporator On the connecting pipeline of the gas pipe 4b of the evaporator, the first heat pump valve 11 is arranged on the connecting pipeline between the exhaust port 7 of the compressor and the gas pipe 4b of the evaporator, and the second heat pump valve 12 is arranged on the suction of the compressor. On the connecting pipeline between port 8 and gas pipe 2a of the evaporative...

Embodiment 3

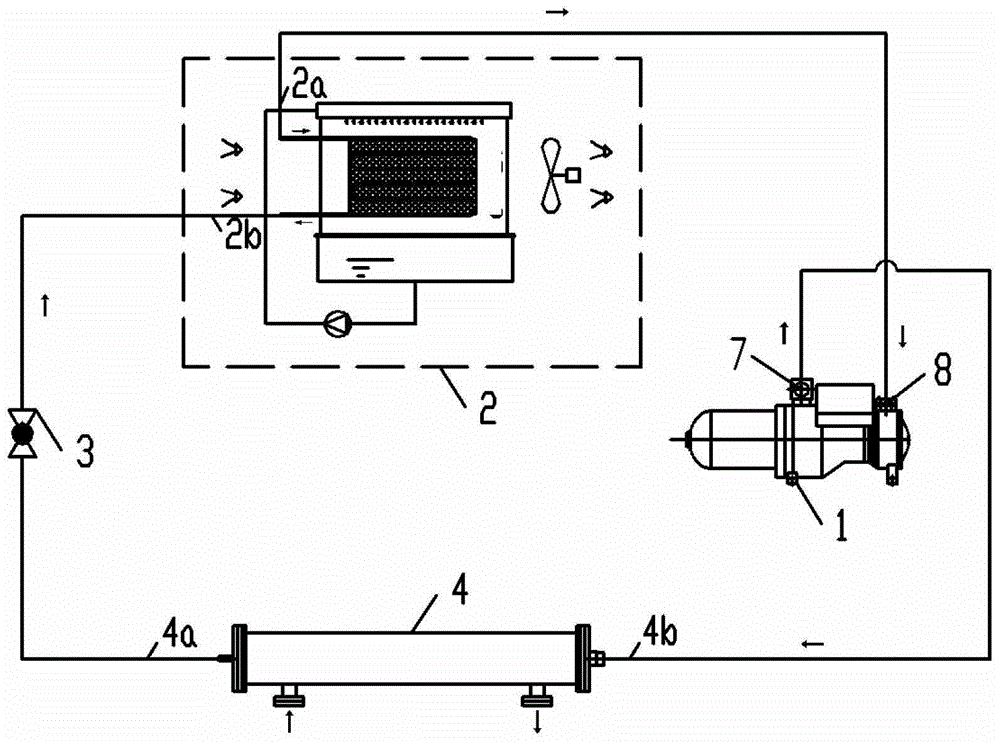

[0050] Figure 4 It shows a schematic diagram of the principle of the water chiller of the present invention using a two-position three-way reversing valve. Compared with Embodiment 1, the difference is that the exhaust port 7 of the compressor 1 is provided with a first two-position three-way Reversing valve 13, the suction port 8 of the compressor is provided with a second two-position three-way reversing valve 14; the two outlets of the first two-position three-way reversing valve 13 are respectively connected to the gas pipe 2a and the gas pipe 2a of the evaporative condenser The gas pipe 4b of the evaporator is connected, and the two inlets of the second two-position three-way reversing valve 14 are respectively connected with the gas pipe 2a of the evaporative condenser and the gas pipe 4b of the evaporator. Also, the evaporative condenser 2 employs packing-coupled longitudinally arranged coils.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com