Gravity center measurement instrument based on moment balance principle

A technology of torque balance and measuring instrument, which is applied in static/dynamic balance test, machine/structural component test, instrument, etc., and can solve problems such as high technical cost, large degree of freedom, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

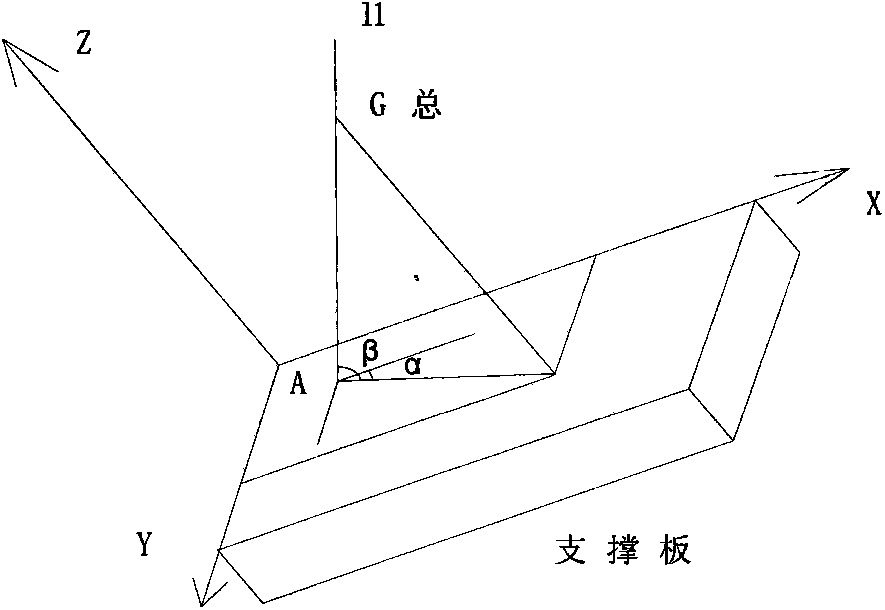

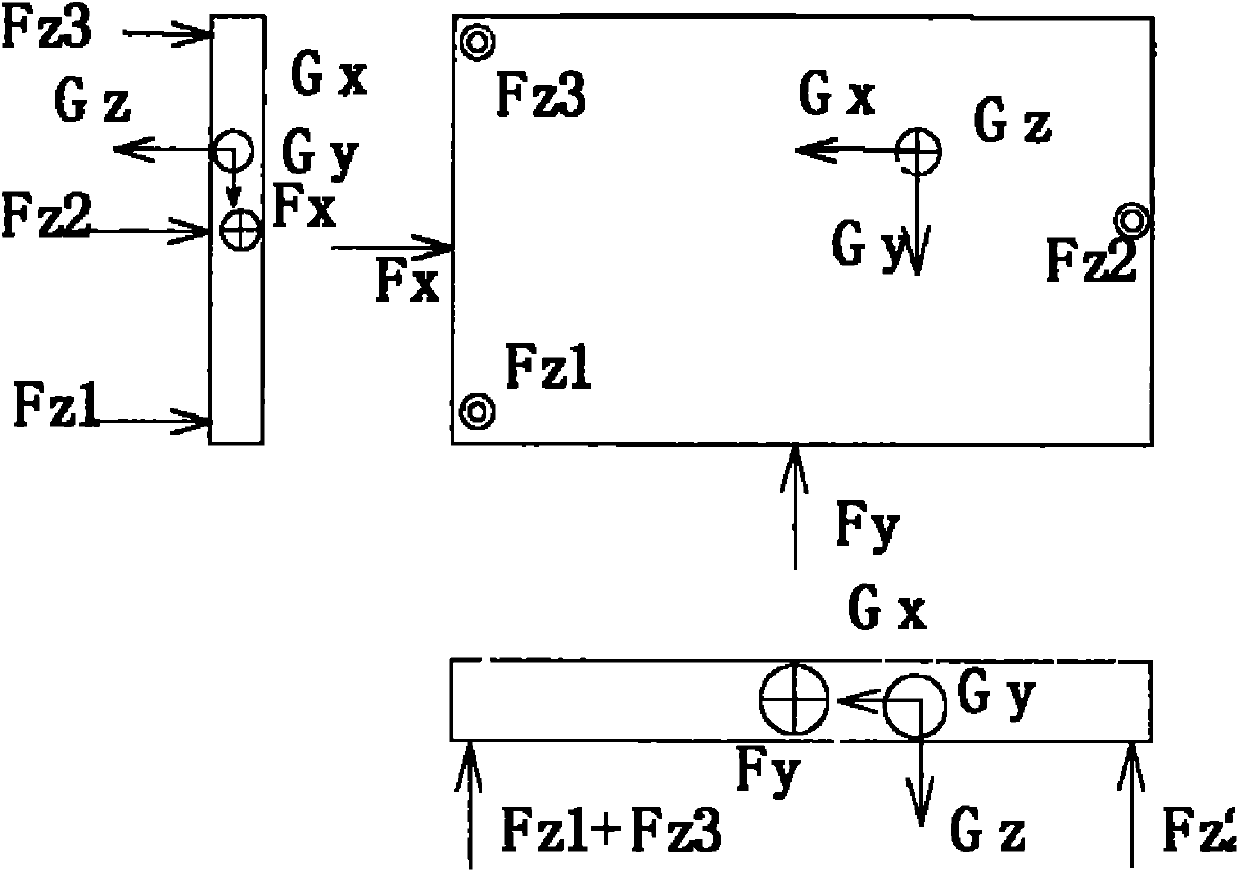

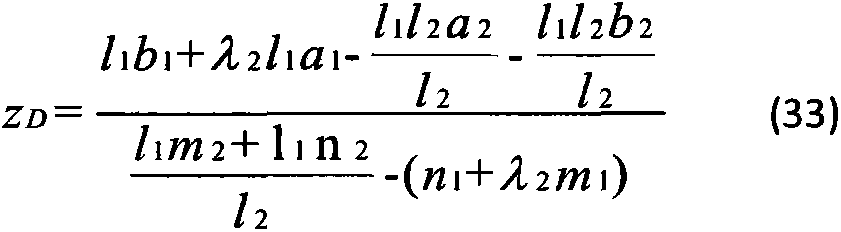

[0010] The line of action of the gravity of an object always passes through the center of gravity of the object. If the object is placed on a slanted plate of known size, and a corner of the plate is used as the origin to establish a spatial rectangular coordinate system, then there must be an intersection between the line of gravity and the surface of the plate. , according to the principle of space moment balance, the coordinates of this point of action relative to the coordinate system on the plate can be obtained. Let this point be point A, and its line of action of gravity passes. At the same time, the direction of the line of action of gravity can be obtained by balancing the space moment The direction vector of the gravitational action line obtained by the principle relative to the component forces in the three directions of the coordinates on the plate is obtained. According to the principle of knowing a point on the line and the direction vector of the line in linear a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com