Electronic horn driven by constant power and implementation method thereof

An electronic horn and constant power technology, which is applied in the direction of sounding equipment and instruments, can solve the problems of inability to achieve accurate control, inability to accurately control driving power, inability to eliminate failure modes, etc., and achieve the effect of eliminating speaker noise and shortening the life of the speaker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

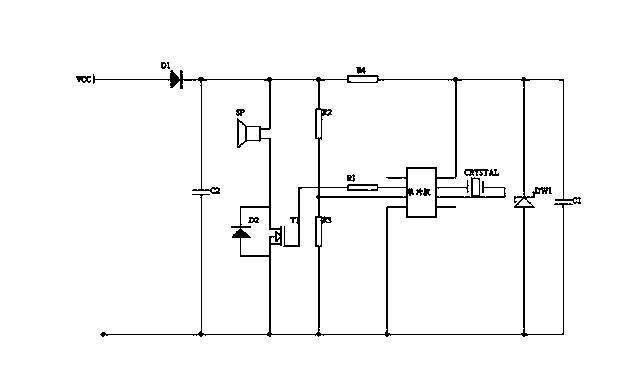

[0012] figure 1 It is a circuit diagram of an electronic horn driven by constant power according to an embodiment of the present invention.

[0013] Such as figure 1 As shown, the circuit diagram of this embodiment includes a power supply part, a power amplification part, a horn sound signal generation part and a supply voltage detection part.

[0014] The power supply part includes a series voltage stabilizing circuit composed of an anti-reverse polarity diode D1, a current limiting resistor R4, and a voltage stabilizing diode DW1. The anode of the anti-reverse polarity diode D1 is connected to the positive terminal VCC of the power supply, and the cathode is connected to the current limiting resistor R4. The capacitor C1 is connected in parallel with the Zener diode DW1, and then connected between the negative ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com