Safety fill tank system pressurized by separate nitrogen tank

A technology of safe injection and nitrogen, which is applied in a field of application, can solve problems such as unsatisfactory devices or methods, and achieve the effect of increasing the injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

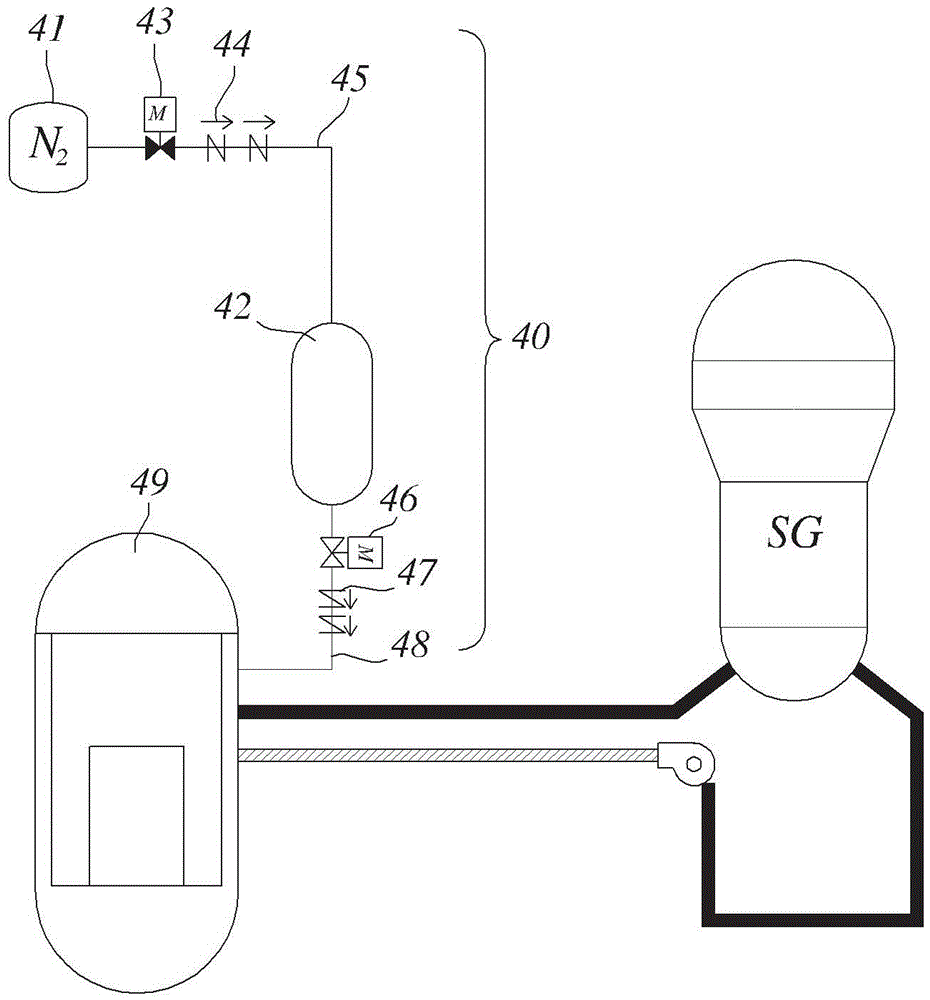

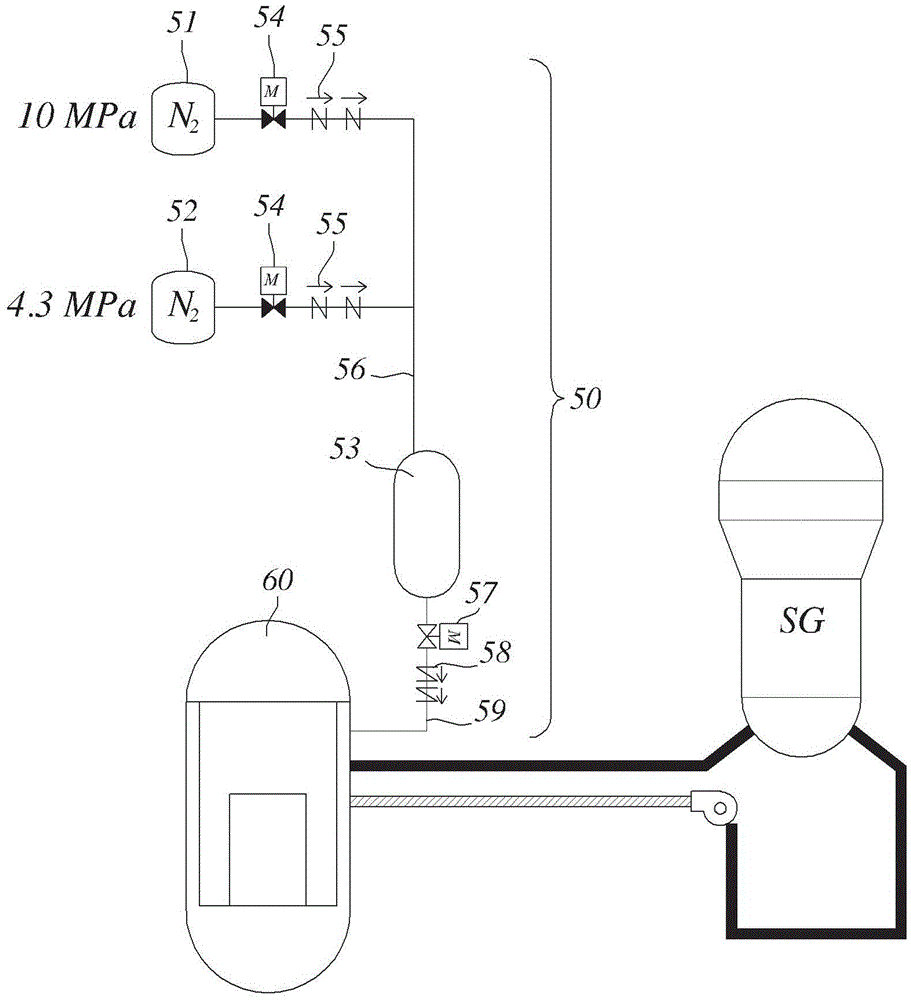

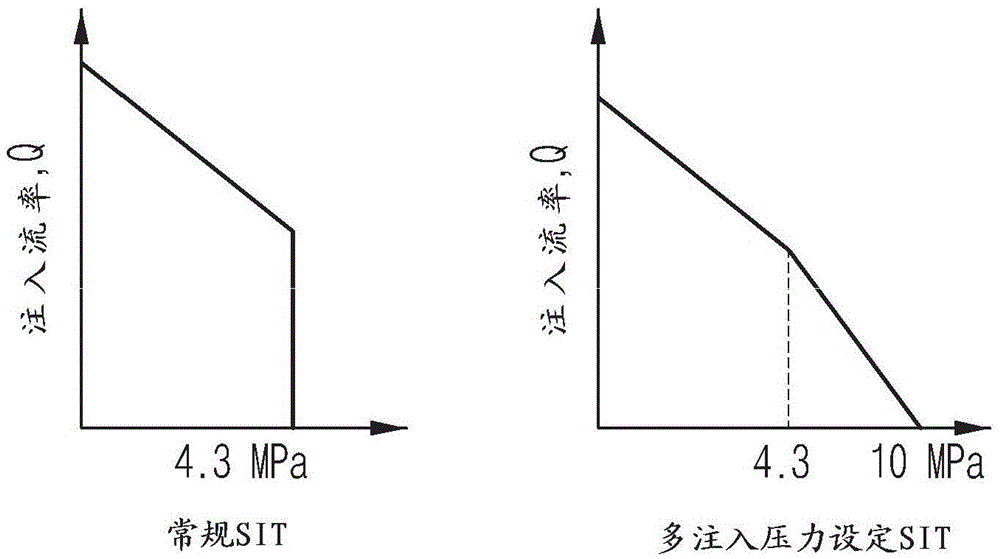

[0038] Hereinafter, a nitrogen tank separation type safety injection tank system pressurized by a separate nitrogen tank according to the present invention will be described in detail with reference to the accompanying drawings.

[0039] Here, it should be noted that the following description only relates to the embodiments for realizing the present invention, but the present invention is not limited to the following embodiments described herein.

[0040] In other words, as will be described later, the present invention relates to a nitrogen tank separate type safety injection tank system pressurized by a separate nitrogen tank in which the nitrogen tank is separated from the emergency core cooling The water tanks are separated from each other, and the two tanks are connected by pipes, thereby substantially preventing phase contact between the emergency core cooling water and the nitrogen gas at the free surface in the conventional safety injection tank when in an operational s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com