Flat transposed aluminum conductor with cooling channel

A cooling channel and aluminum wire technology, applied in the direction of conductors, insulated conductors, flat/ribbon cables, etc., can solve the problem that reactors and transformers reach very high temperatures, which affect the efficiency and safety of power grid power supply, reactors, and transformer windings. Advanced problems, to achieve the effect of increasing the rate of qualified products, reducing labor intensity, and ensuring the quality of power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

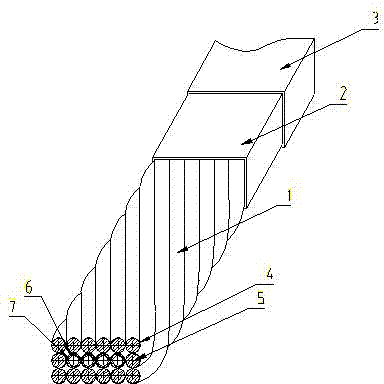

[0014] see figure 1 , a flat transposed aluminum conductor with a cooling channel, comprising a flat transposed aluminum conductor core 1, a film insulating layer 2, a composite insulating layer 3 and a cooling channel soft copper tube 7; the flat transposed aluminum conductor core 1 It is an orderly arranged transposition rectangular strand made of a plurality of defect-free single-strand round aluminum wires 5 with a round aluminum wire film wrapping layer 4 surrounding a cooling channel soft copper tube 7 with an insulating film wrapping layer 6 wire; the film insulating layer 2 is a wrapping layer of two layers of insulating film; the composite insulating layer 3 is a composite non-woven wrapping layer with an insulating film; the film insulating layer 2 is wrapped i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com