Variable-diameter biological drip-filter device for gas processing

A technology for biological trickling filtration and gas treatment, which is used in air quality improvement, dispersed particle separation, chemical instruments and methods, etc. It can solve the problems of high pressure drop, easy blockage, and poor circulation of nutrient solution, and achieve a large inlet cross-sectional area. , The effect of removing large load and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

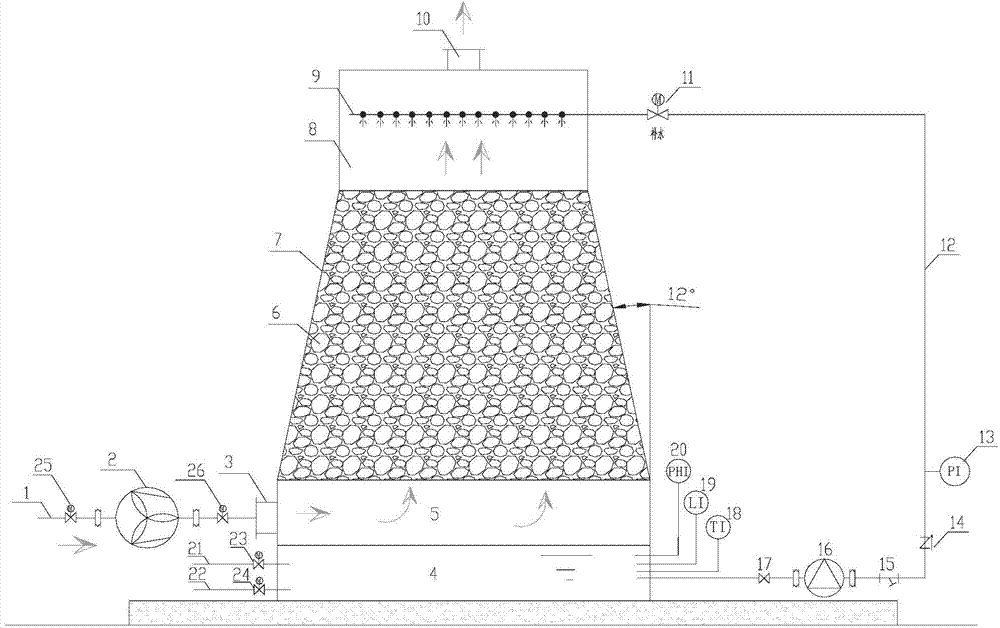

[0019] Attached below figure 1 To illustrate the specific implementation. A variable-diameter biological trickling filter device for treating gas, including an air inlet pipe (1), an induced draft fan (2), an air inlet (3), a liquid storage tank (4), an air inlet chamber (5), and a composite filler ( 6), biological filter tower (7), air outlet chamber (8), spray water pipe (9), air outlet pipe (10), spray water solenoid valve (11), circulating water pipe (12), water pressure gauge (13 ), outlet pipe shut-off valve (14), pipe filter (15), circulating water pump (16), butterfly valve (17), temperature sensor (18), liquid level gauge (19), pH value monitor (20), water replenishment Pipe (21), drain pipe (22), replenishment solenoid valve (23), drain solenoid valve (24), fan inlet air valve (25), fan outlet air valve (26). Among them, the air inlet pipe (1), the fan inlet air valve (25), the induced draft fan (2), the fan outlet air valve (26), and the air inlet of the biologica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com