Flotation recovery method of micro-fine particle ilmenite

A recovery method, ilmenite technology, applied in flotation, solid separation, etc., can solve the problems of high operating cost, complex process, long process, etc., and achieve the goal of improving the overall recovery rate, simple process flow, and increasing recovery efforts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

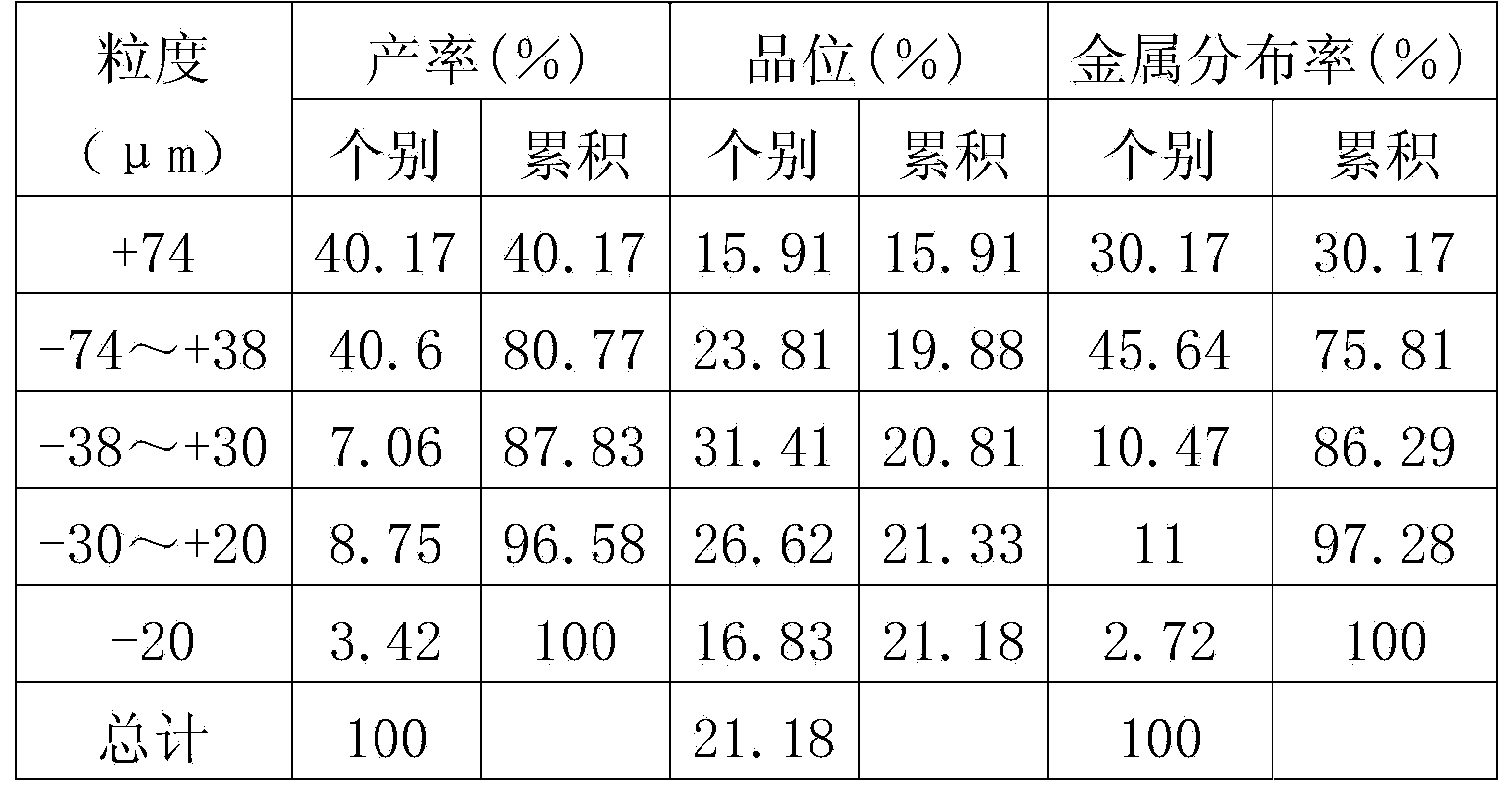

[0020] Hereinafter, the flotation recovery method of fine-grained ilmenite according to an exemplary embodiment of the present invention will be described in detail with reference to the accompanying drawings. It should be noted that, in this specification, unless otherwise specified, the percentages involved refer to percentages by weight.

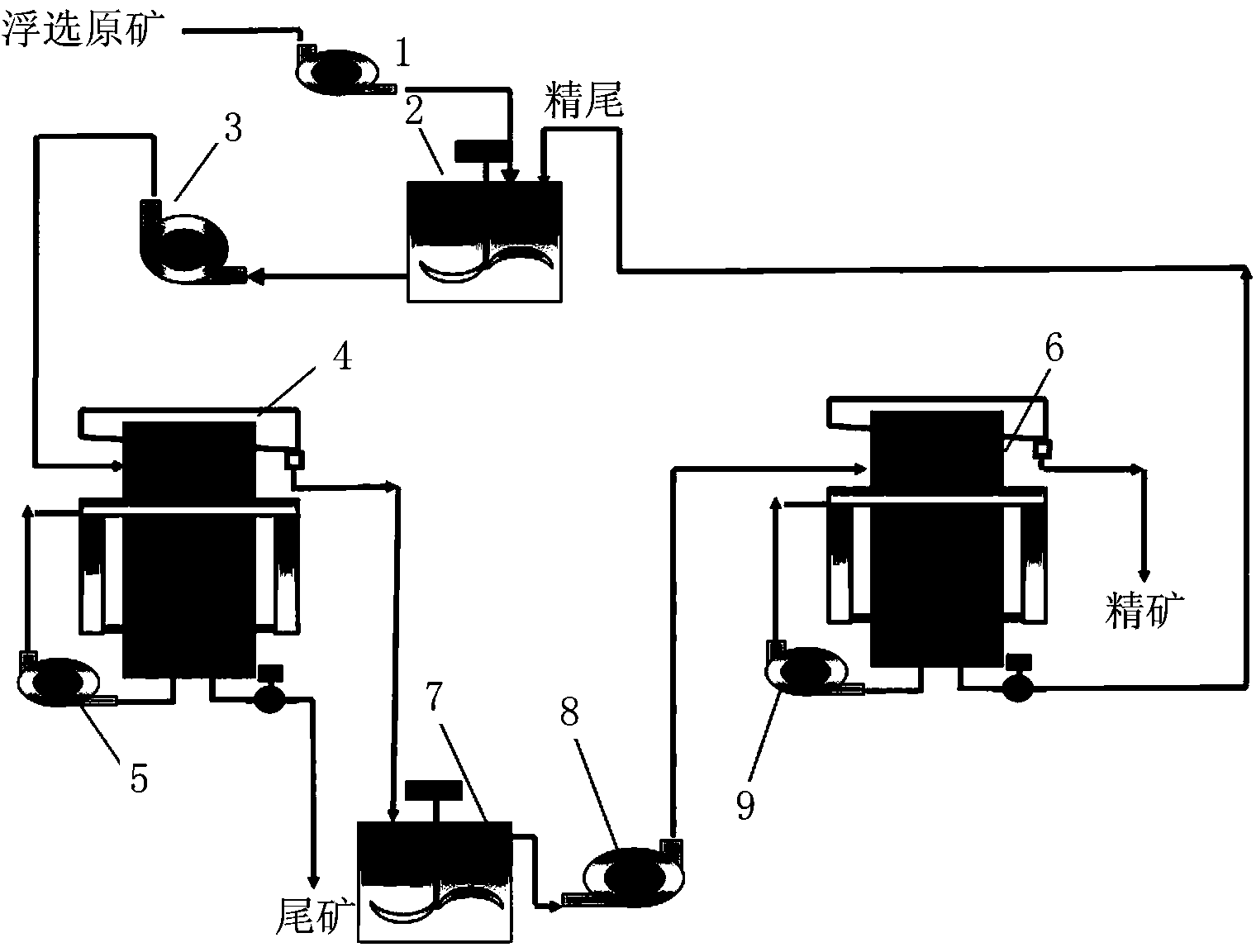

[0021] The specific idea of the present invention is to use a cyclone-static micro-bubble flotation column for flotation, and provide a new and effective flotation recovery method for fine-grained ilmenite by optimizing the process flow and reagent system.

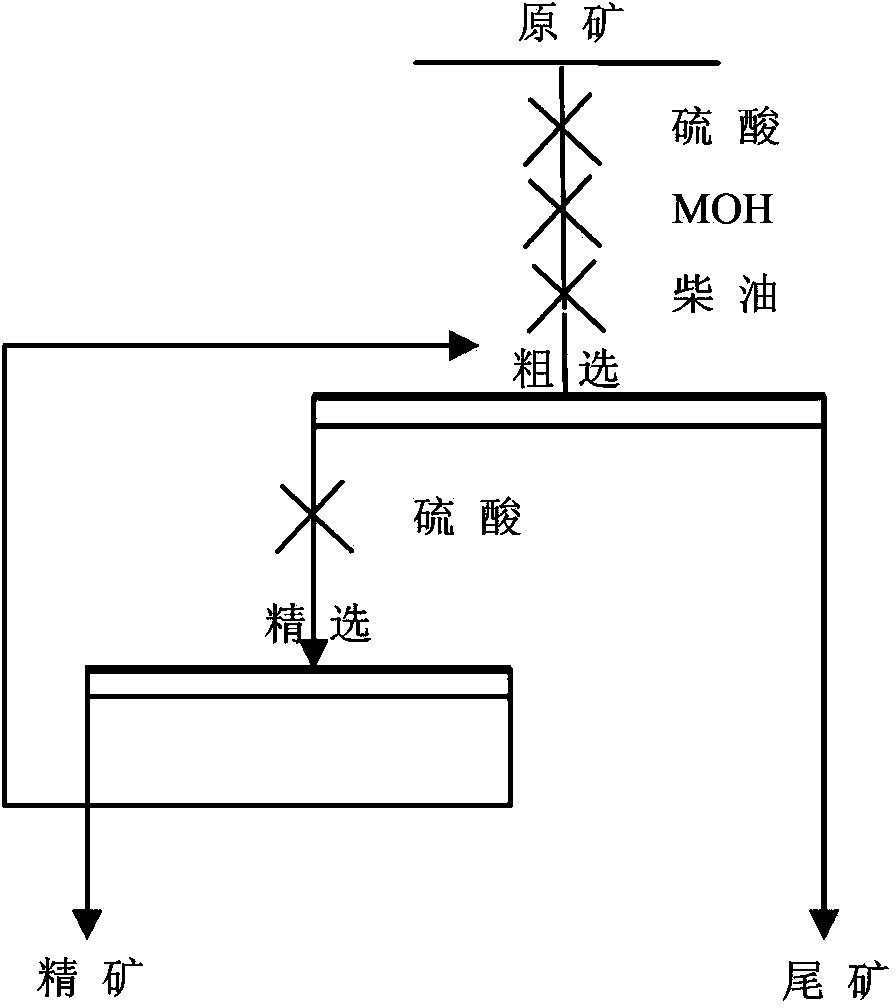

[0022] Such as figure 1 As shown, the flotation recovery method of fine-grained ilmenite according to an exemplary embodiment of the present invention includes the following steps: 1) roughing the flotation raw ore through the first cyclone-static micro-bubble flotation column, and using Sulfuric acid is used as regulator, and MOH and diesel oil are used as collectors to obtain rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com