Glass imbedded mold injection molding method and product thereof

A technology of injection molding and implantation, which can be used in household appliances, other household appliances, household components, etc., and can solve the problems of common glass being easily broken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

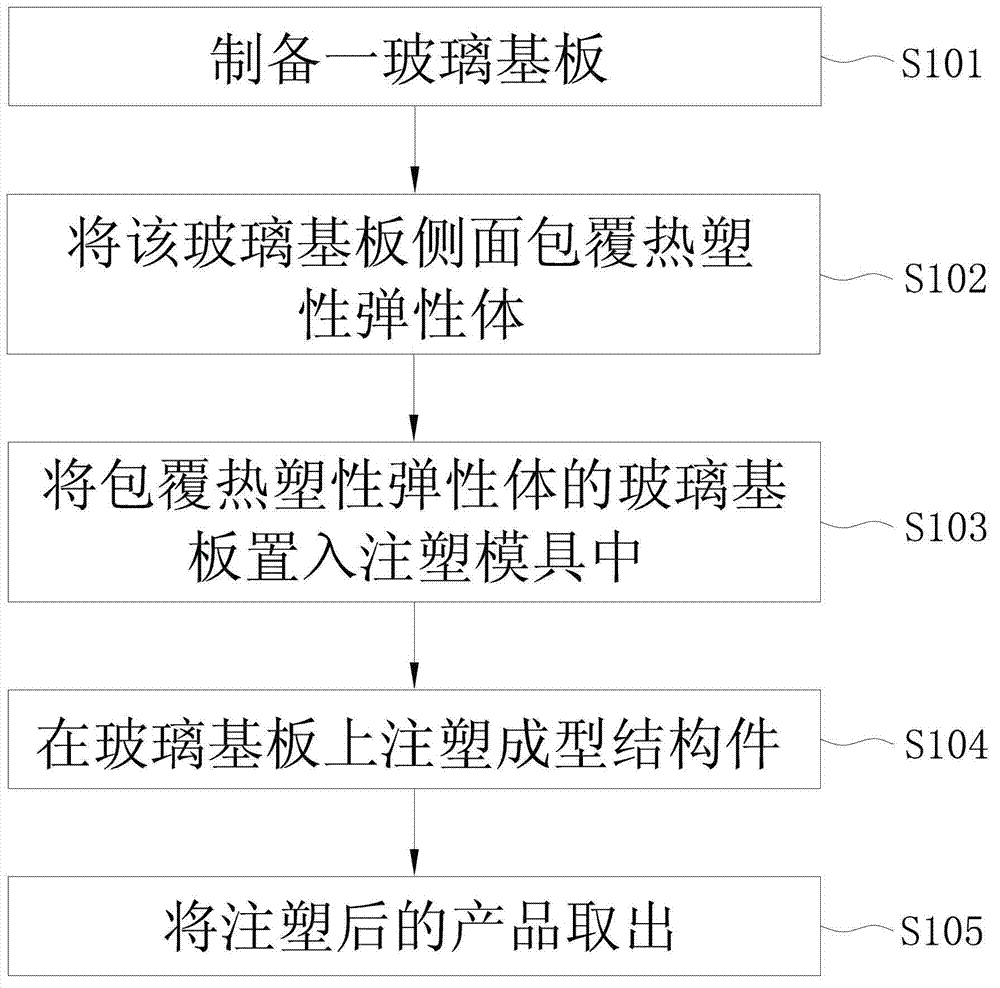

[0026] See figure 1 and figure 2 As shown, in this embodiment, the glass inserting mold injection molding method of the present invention includes the following steps:

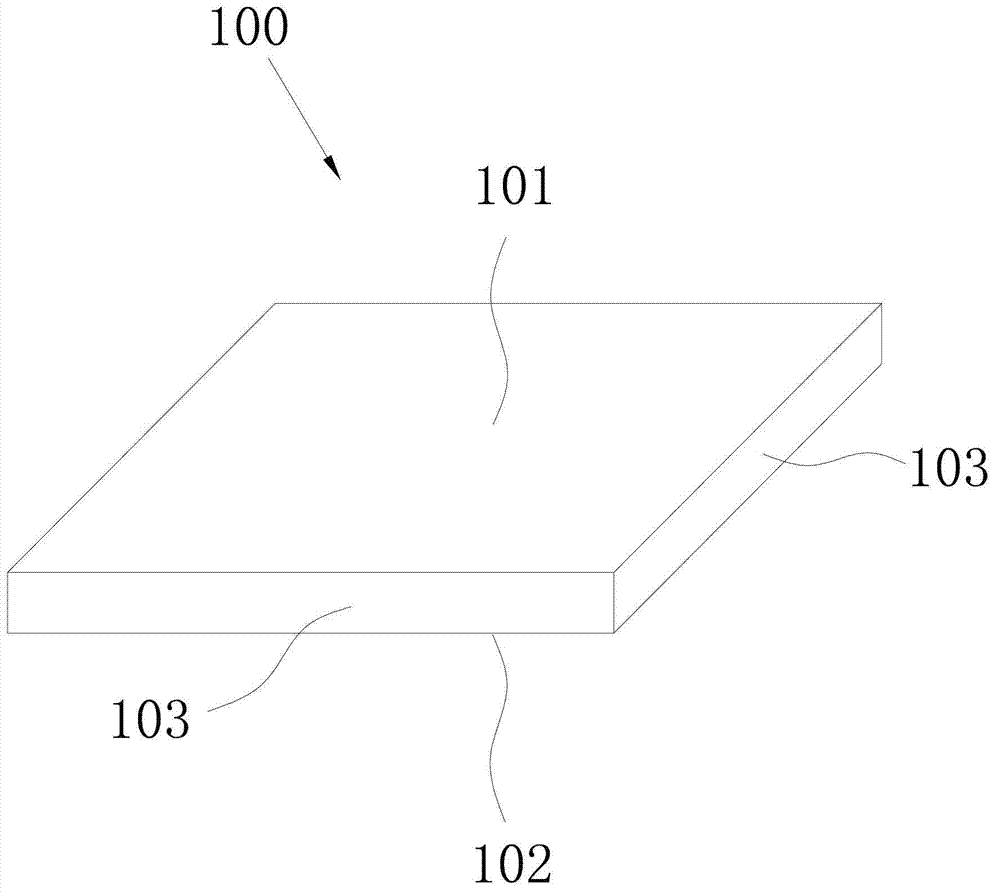

[0027] Step S101: Prepare a glass substrate 100. The glass substrate 100 has a bottom surface 102, a top surface 101, and four side surfaces 103 connecting the bottom surface 102 and the top surface 101. The glass substrate 100 is used in electronic products and can be used as electronic products Touch surface, or other structural parts of electronic products.

[0028] Step S102: Wrap the side 103 of the glass substrate 100 with a thermoplastic elastomer frame. In this embodiment, the method of wrapping the thermoplastic elastomer frame is: dispensing or sticking double-sided tape on the glass substrate 100, and then applying the thermoplastic elastomer The body is attached to the side surface 103 of the glass substrate 100 to combine the glass substrate 100 with the thermoplastic elastomer.

[0029] Step S103: Pl...

Embodiment 2

[0033] In this embodiment, the glass inserting mold injection molding method of the present invention includes the following steps:

[0034] Step S201: Prepare a glass substrate 100. The glass substrate 100 has a bottom surface 102, a top surface 101, and four side surfaces 103 connecting the bottom surface 102 and the top surface 101. The glass substrate 100 is used in electronic products and can be used as electronic products Touch surface, or other structural parts of electronic products.

[0035] Step S202: wrap the side 103 of the glass substrate 100 with a thermoplastic elastomer frame. In this embodiment, the way of covering the frame of the thermoplastic elastomer is to apply glue on the side 103 of the glass substrate 100 or partially glue on the bottom surface 102, and then put the glass substrate 100 into a single-color machine injection mold; The temperature of the mold is increased and the pressure is increased; then the liquid thermoplastic elastomer is injected into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com