Photo-curing 3D (three dimensional) printer based on helical scanning and flexible interface

A 3D printer and helical scanning technology, which is applied in the field of light-curing 3D printers, can solve problems such as short coating life, economical decline, and complex coating process, so as to ensure work efficiency and machine cost, and improve scanning speed and curing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

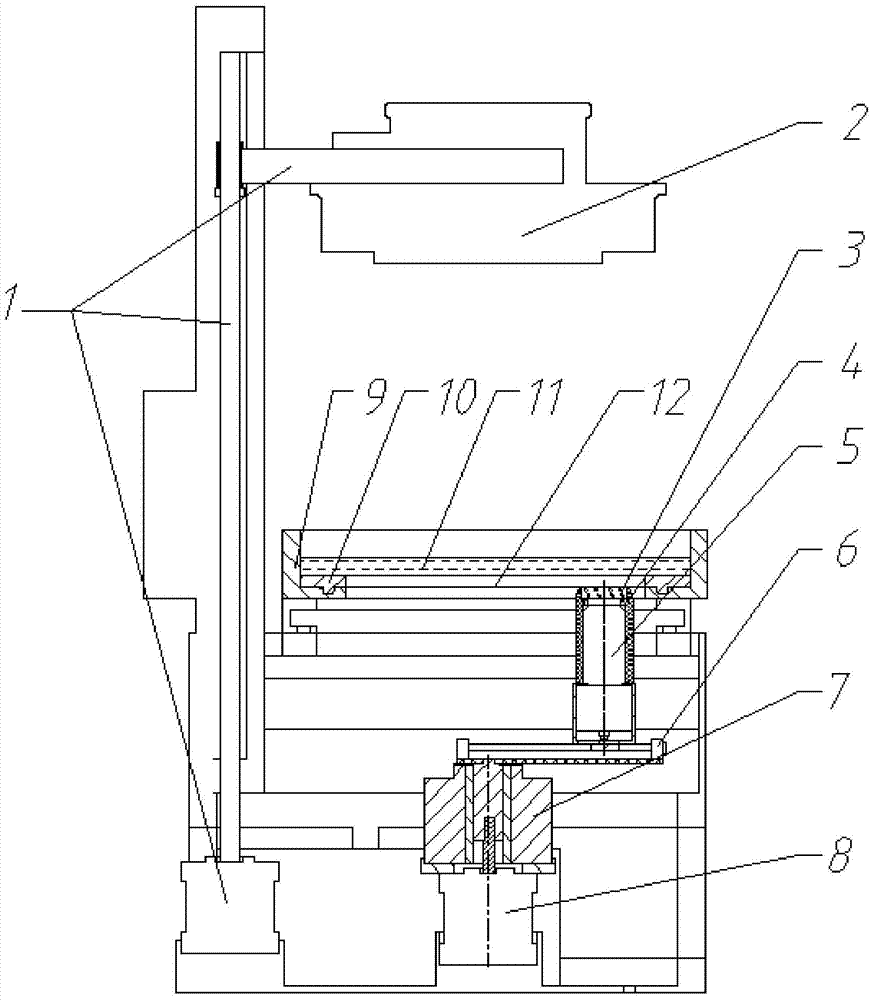

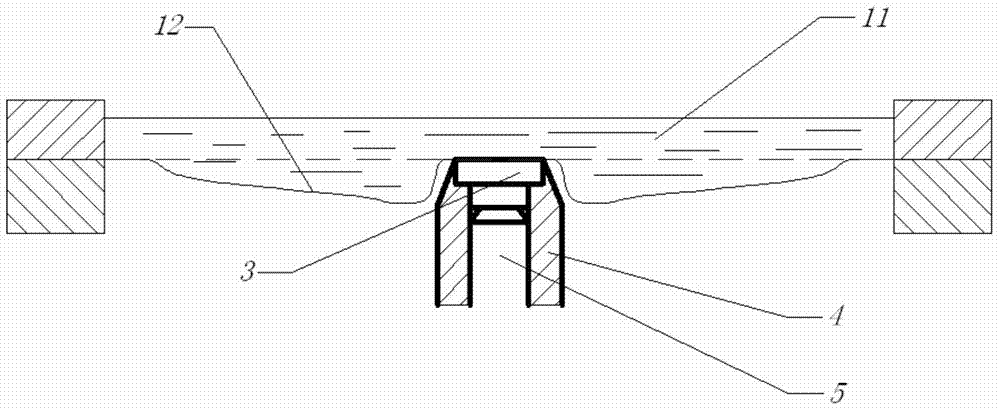

[0014] refer to figure 1 , a light-curing 3D printer based on spiral scanning and flexible interface, including a stepping motor 8 in the middle of the bottom of the machine, the output of the stepping motor 8 is connected to the electric slip ring 7, and the linear feed motion platform 6 is arranged on the electric slip ring 7 The linear feed motion platform 6 rotates on the plane through the electric slip ring 7, the integrated LED lens 5 is connected to the linear feed motion platform 6, and the linear feed motion platform 6 drives the integrated LED lens 5 to perform linear motion, stepping The combination of the rotary motion output by the motor 8 and the linear motion makes the integrated LED lens 5 perform a planar spiral scanning motion on the plane.

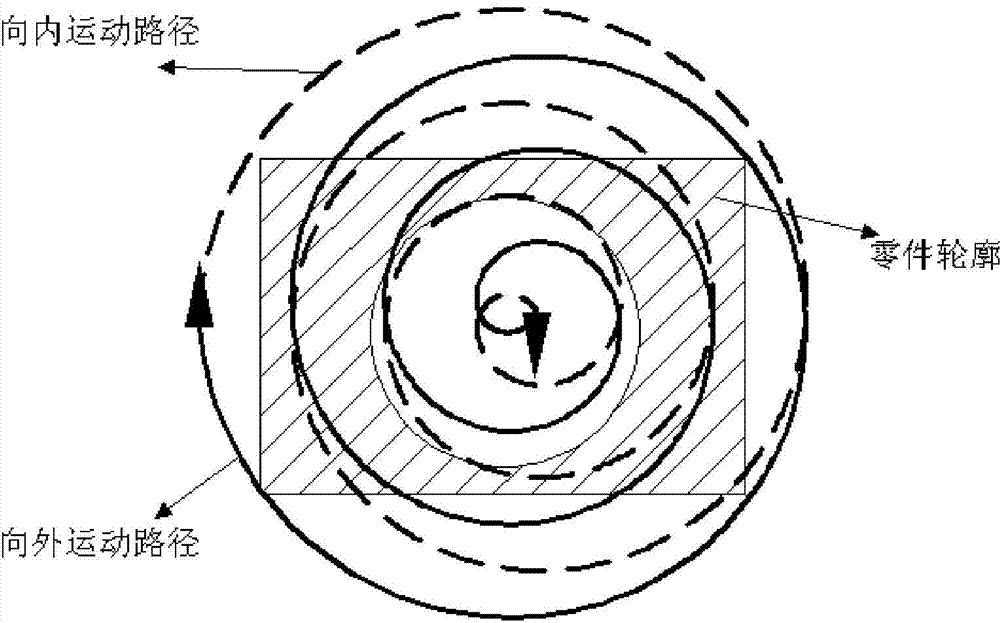

[0015] refer to figure 2 , the scanning path is an Archimedes spiral. When scanning the first lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com