Method for sucking printing ink, printing device, and print head for same and

A printing device and printing ink technology, used in packaging, printing, typewriters, etc., can solve problems such as the reduction of the quality of printed images, and achieve the effect of small mechanical pollution and high printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

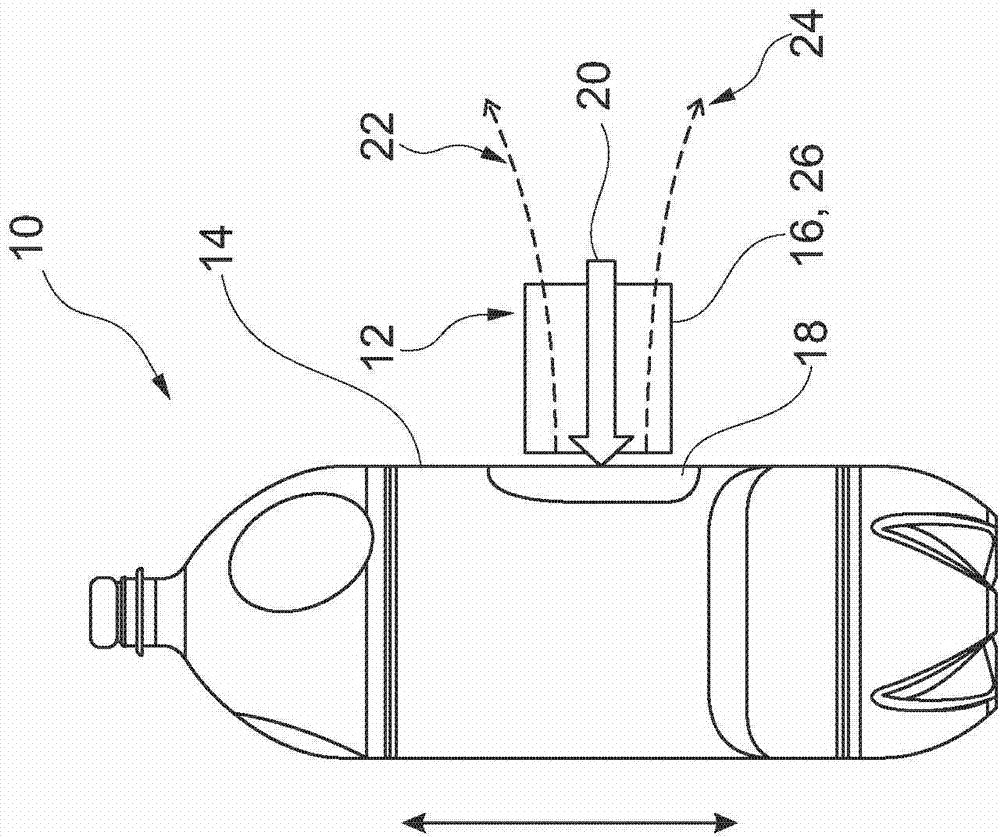

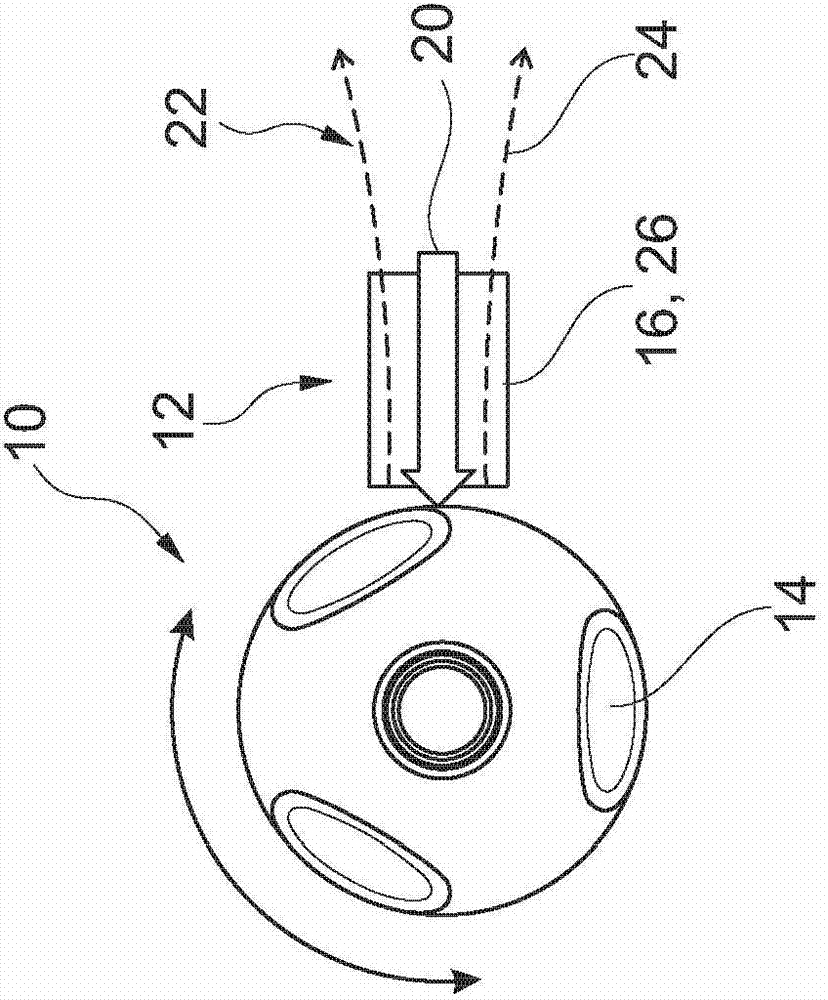

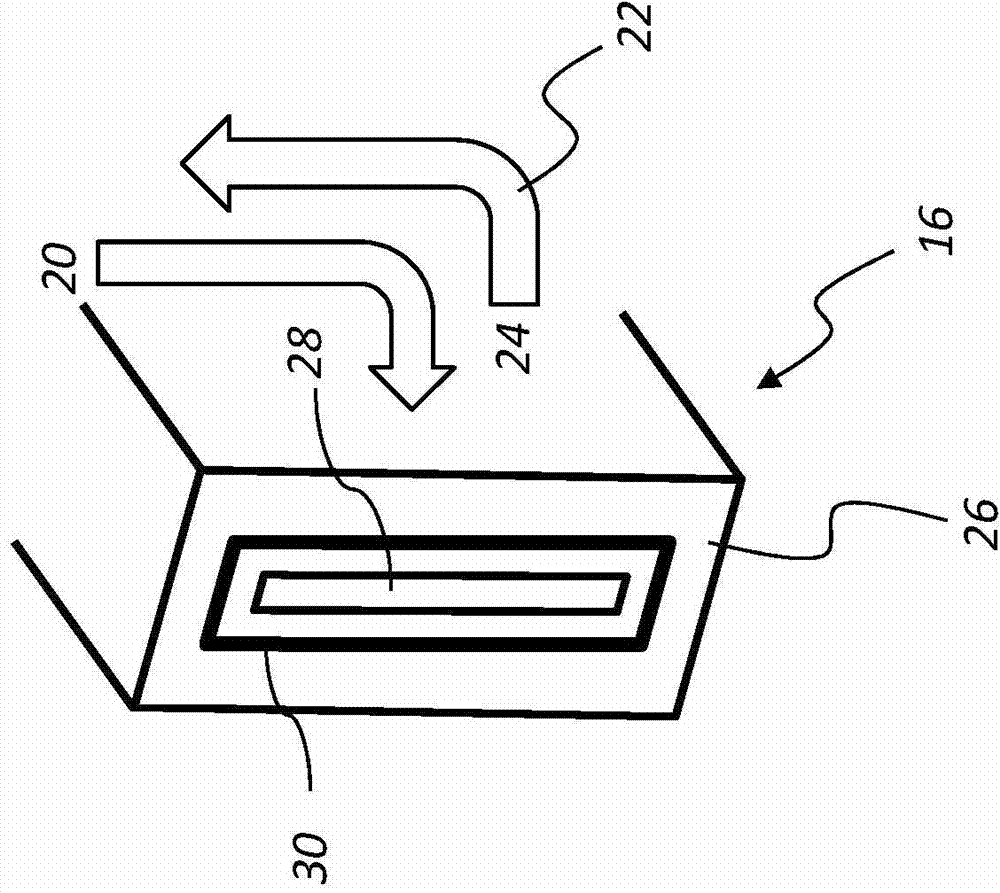

[0034] The two schematic views of FIG. 1 show a plastic container 10 which has been printed on its outer surface 14 by means of a printing device 12 according to the invention in a direct printing method. The plastic container 10 may especially be a PET container, as it is widely used in the beverage industry. After printing, the container 10 can be filled with a liquid, such as a beverage, in a downstream filling station and then closed hermetically at the opening on its top side. The printing device 12 comprises at least one printing head 16 which is at least during the printing process in a defined relative position with respect to the printing area 18 on the container surface 14 and which is prepared to apply liquid printing ink 20 to the container 10 or on the bottle. After the container 10 has been printed, the printing ink 20 applied in the printing zone 18 can be cured, for example by means of UV curing, by means of heat or by other suitable measures. This curing (no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com