Toning lotion bottle

A lotion and bottle cap technology, applied in the field of lotion bottles, can solve the problem of easily polluted lotion and achieve the effect of reducing pollution and preventing direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

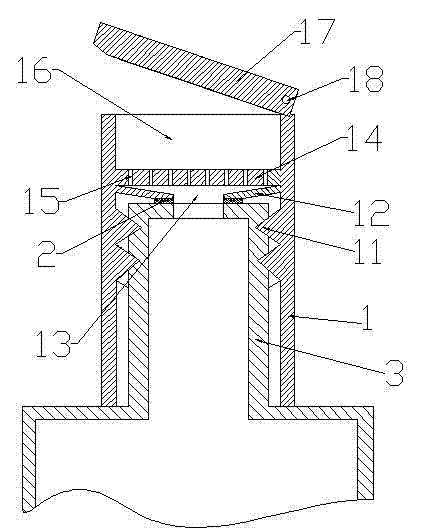

[0012] The specific embodiment of the present invention is described in conjunction with accompanying drawing, as figure 1 As shown, the lotion bottle includes a bottle body 3 and a bottle cap 1. The bottle body 3 has a bottle mouth, and the bottle mouth has external threads that match the internal threads 11 of the bottle cap 1. The top of the bottle cap 1 has a flip cap 17, The bottom of the flip cover 17 and the side wall of the bottle cap 1 form a cavity 16. There is a partition 14 at the bottom of the cavity 16. There is an inverted cone-shaped bottom plate 12 below the partition 14. The inverted cone-shaped bottom plate 12 and the partition 14 form an inverted cone. Cavity 13, a plurality of evenly distributed small holes 15 on the partition 14, the small holes connect the cavity 16 and the inverted conical cavity 13, there is a hole in the bottom of the inverted conical bottom plate 12, and the hole is pressed tightly with the bottle mouth And interlinked.

[0013] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com