Tail aluminum foil treatment method for improving safety test of lithium ion battery

A lithium-ion battery, safety testing technology, applied in the manufacture of battery electrodes, secondary batteries, electrolyte batteries, etc., can solve problems such as thermal runaway, and achieve the effect of preventing direct contact and not easy to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

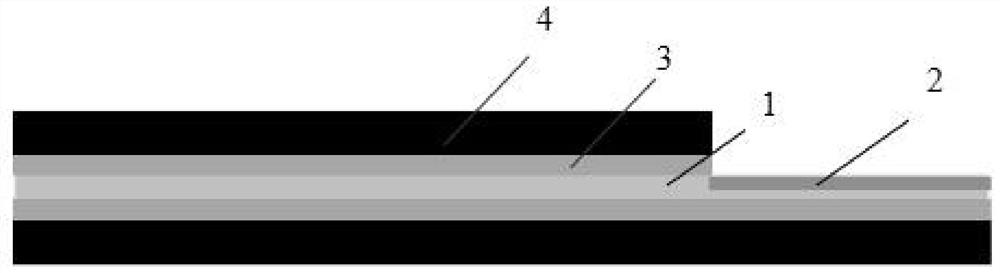

[0035] Tail foil treatments for improved safety testing of lithium-ion batteries, including:

[0036] Step 1, oxidizing the surface of the metal foil 1 at the tail of the short film surface of the cathode sheet;

[0037] Step 2, coating the slurry of the safety coating 3 on the surface of the metal foil 1, and then baking;

[0038] Step 3, coating the cathode active material slurry 4 on the surface of the safety coating 3, and then baking;

[0039] Step 4: Carry out rolling, slitting, winding, and top-side sealing of the baked cathode sheet to form a battery cell.

[0040] It should be noted that: in the existing structure, the ceramic coating has a certain thickness, resulting in the loss of energy density of the cell; at the same time, the ceramic coating is easy to peel off during the process of acupuncture and foreign matter extrusion, resulting in the exposure of the aluminum foil and the negative electrode active material. A short circuit occurs at the end of the conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com